Laser hardening and cladding

in perfection

Technologies for laser processing

Hardening, repairing, cladding

and additive manufacturing

Whether hardening, repairing, cladding or additive manufacturing – our laser applications can process metallic surfaces in a wide variety of geometries precisely, quickly and economically.

The low energy consumption thanks to precise laser power and various laser settings makes our technologies an energy-efficient and environmentally friendly application.

High processing quality is achieved through permanent laser power control with E-MAqS thermal imaging camera and LompocPro control.

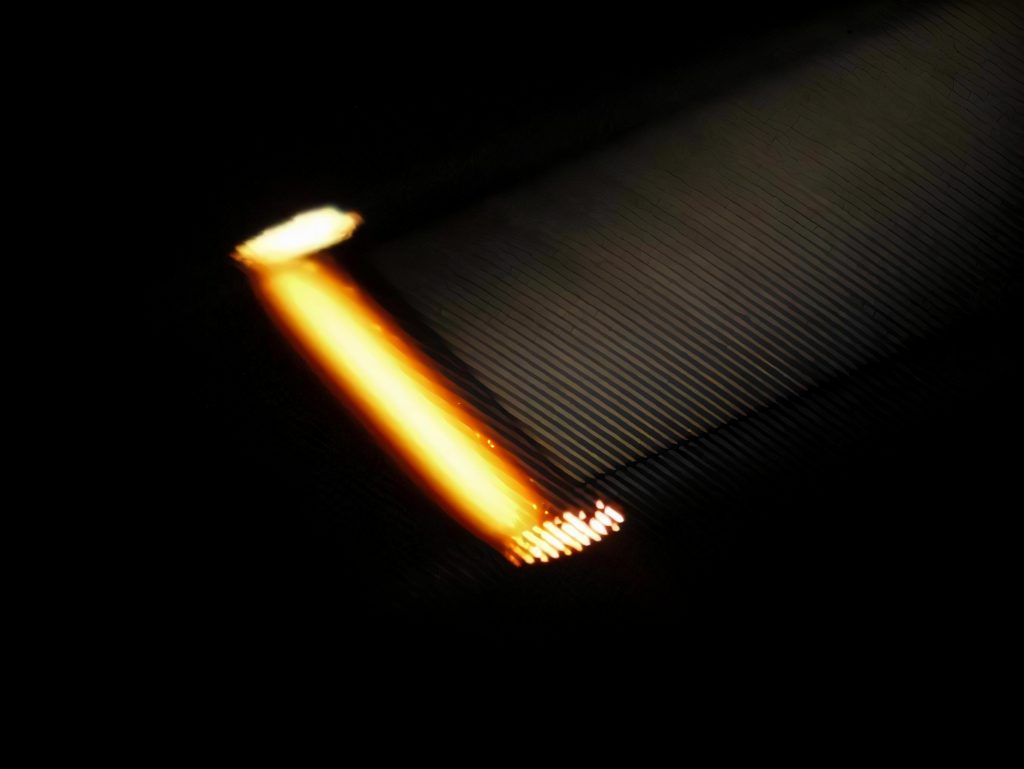

Laser hardening

ALOhard

ALOhard laser hardening is a surface hardening process that produces maximum hardness values on the component surface with a very low energy input. This achieves a specific improvement in the wear behaviour of components.

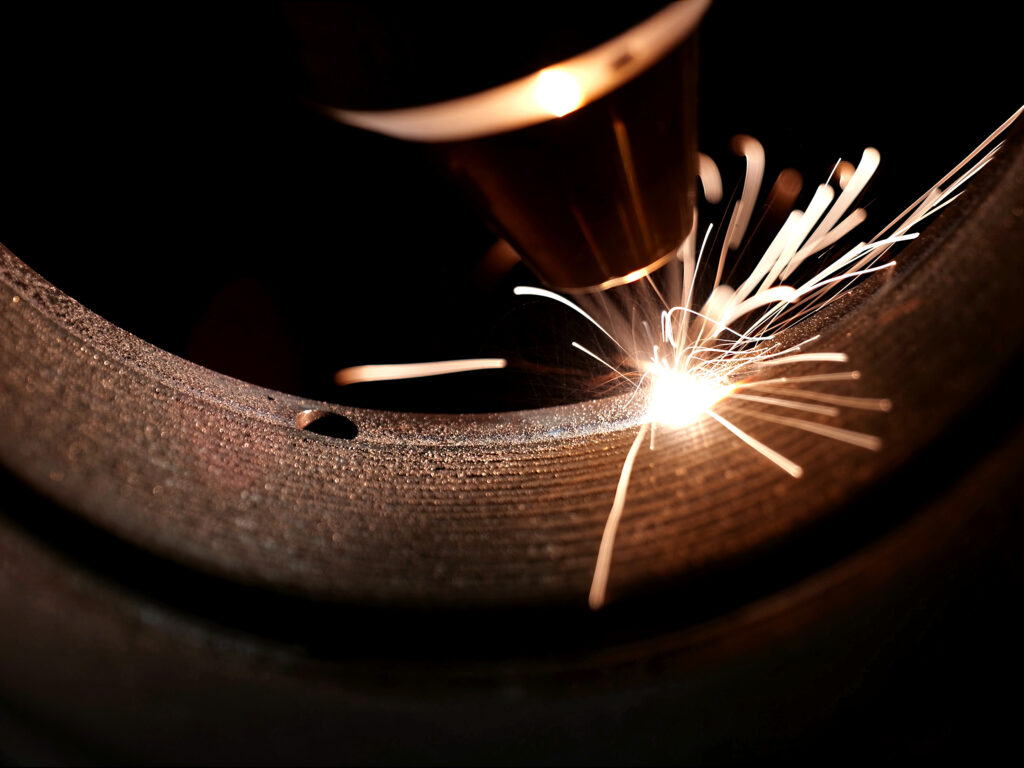

Laser powder cladding

ALOpowder

ALOpowder laser cladding is a manufacturing process in which the laser beam melts a substrate on the surface and a pulverised filler material is introduced into the molten pool via a nozzle.

There are numerous possible applications: corrosion and wear protection, repair, design modification or additive manufacturing of 3D components.

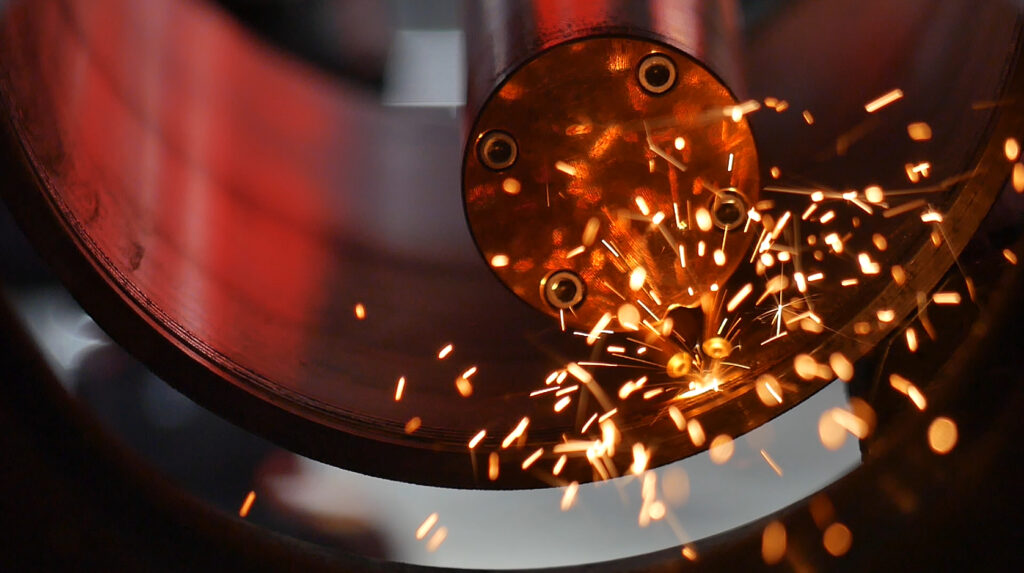

Laser wire cladding

ALOwire

In ALOwire laser wire cladding, the laser beam is split into individual beams using optical elements. These create a localised molten pool on the surface of the base material, into which a wire is fed concentrically.

There are numerous possible applications: corrosion and wear protection, repair, design modification or additive manufacturing of 3D components.

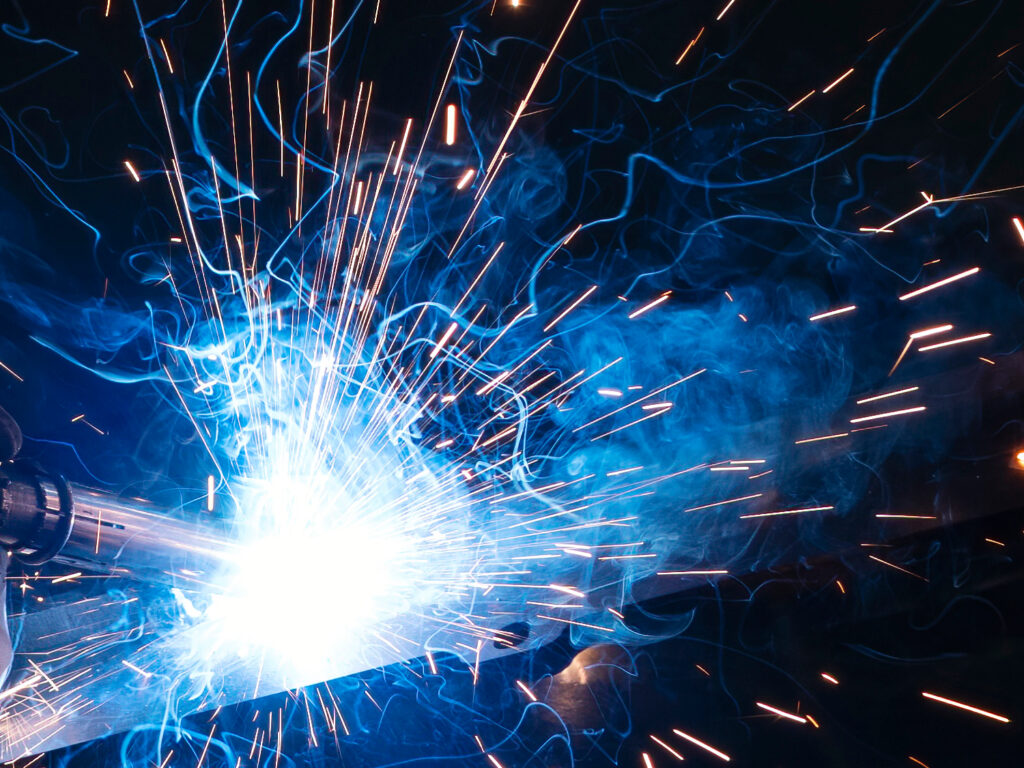

Arc welding

ALOarc

Arc welding is particularly suitable for high deposition rates and is used for cladding and additive manufacturing.

You find our technologies exciting?

Let’s talk.

Find out more about maximum hardness values on highly stressed component surfaces, corrosion and wear protection, repair, design modification or additive manufacturing of 3D components.

Our applications in moving images

Roll it – laser on

Laser hardening

Laser powder cladding

Laser wire cladding