Anlagenbau und Auftragsfertigung

Laserhärten und Auftragschweißen

Was wir für Sie leisten

Anlagenbau und Auftragsfertigung

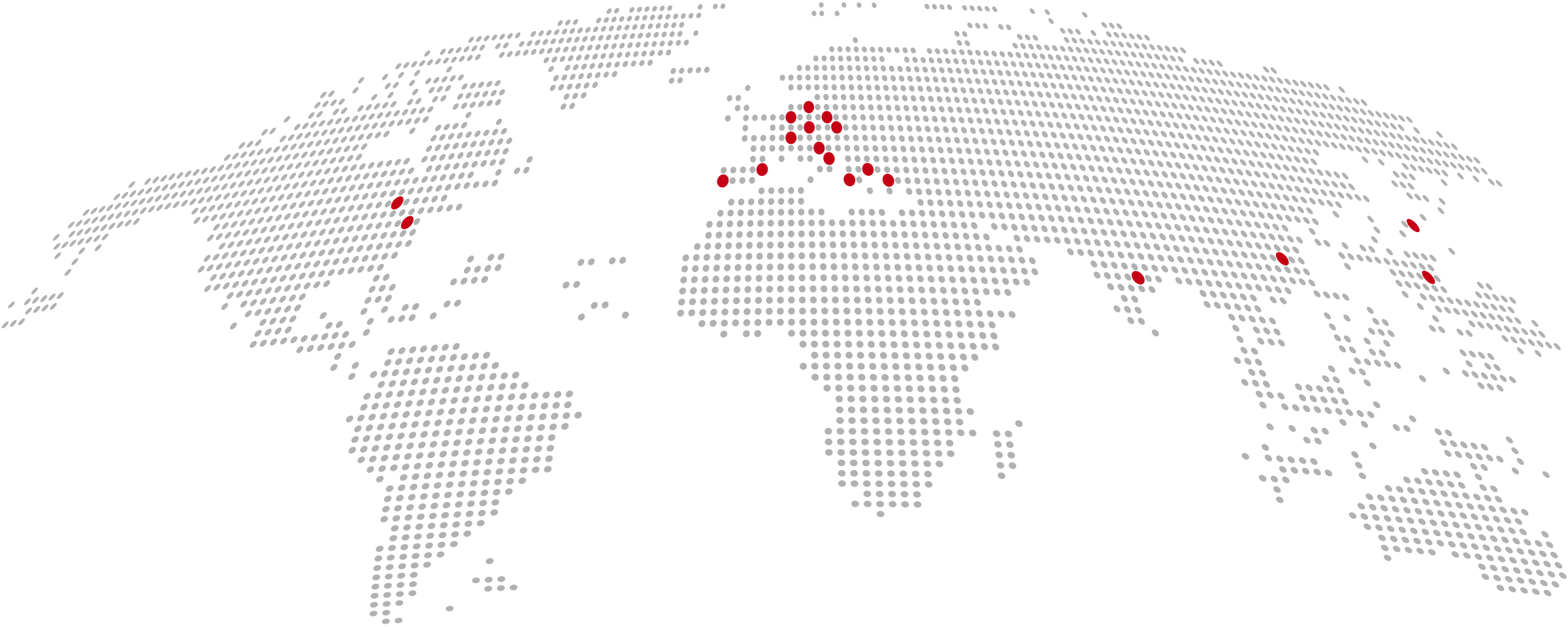

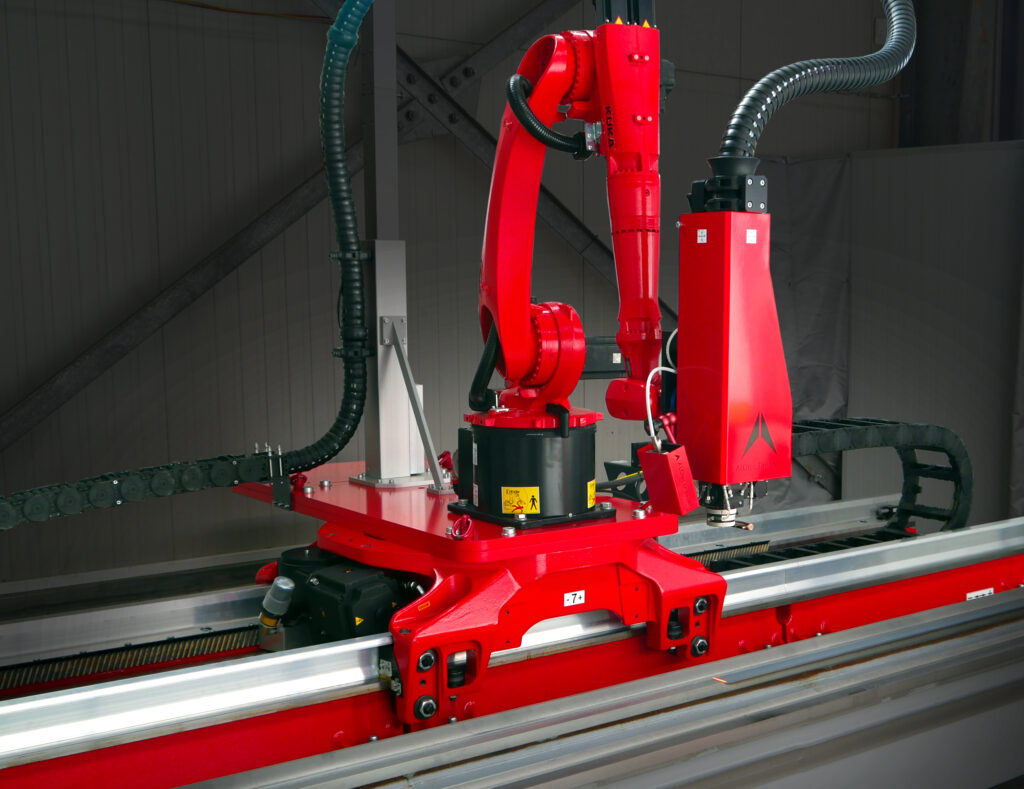

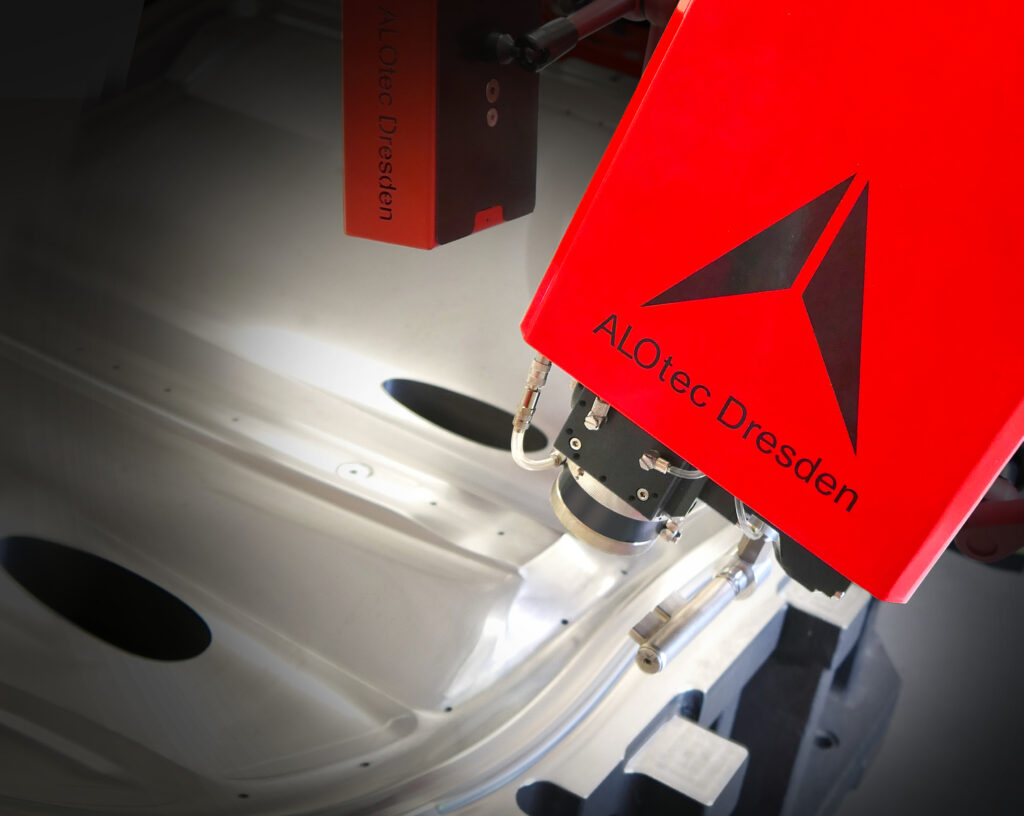

ALOtec Dresden ist ein leistungsstarker Technologiepartner für die metallbearbeitende Industrie, der sich seit über 25 Jahren im Anlagenbau auf die Herstellung von kundenindividuellen und schlüsselfertigen Laseranlagen auf Roboter-Basis zum Laserhärten und Laserauftragschweißen sowie Additive Fertigung spezialisiert hat.

Neben dem bietet die ALOtec Dresden GmbH Dienstleistungen in den Bereichen Laserhärten und Laserauftragschweißen mit Pulver oder Draht an. Diese Lasermaterialbearbeitung kann auch – durch das innovative ALOhybrid-System – vor Ort beim Kunden erfolgen.

Unsere “ALOtec-Innovationen” entstehen aus der langjährigen Erfahrung und täglichen Arbeit in der Auftragsfertigung und Forschung und fließen in Konstruktion und Bau unserer Anlagen mit ein.

Anlagenbau

Härten

Reparatur und Auftragschweißen

Additive

Fertigung

ALOtec – News

Wir sind aktuell

-

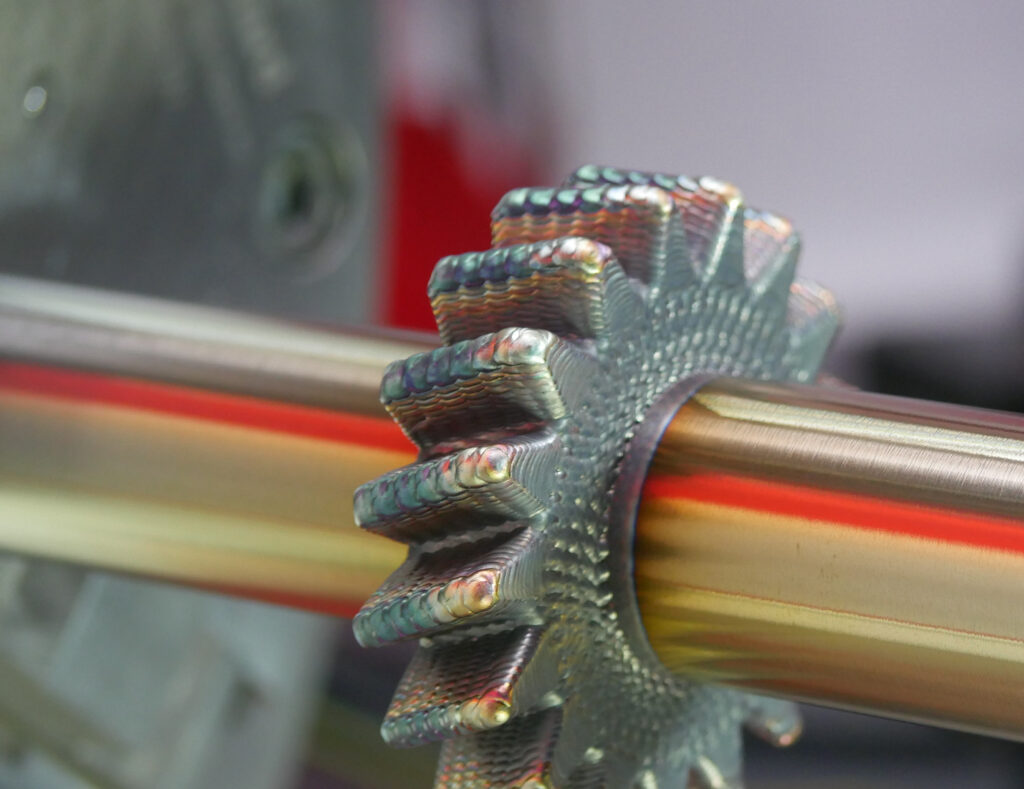

Reparatur einer Flanschwelle

Reparatur lohnt sich – Aufarbeitung von beschädigten Flanschwellen mit Laserpulverauftragschweißen Mit unseren effizienten Laseranlagen und den entsprechenden Technologien wie dem […]

-

Laserhärten mit einem Spiegelsystem

Unser Spiegelsystem kommt beim Laserhärten von komplexen Geometrien mit hohen Kanten und Vertiefungen zum Einsatz. Damit garantieren wir eine optimale […]

-

Messeauftritt auf der NORTEC 2024

Mitte Januar 2024 waren wir auf der Messe NORTEC in Hamburg! Unsere Besucher erhielten tiefe Einblicke in die Welt der […]

Anlagenbau

Skalierbare Laseranlagen

Unsere Laseranlagen können stationär, mobil oder hybrid eingesetzt und um viele weitere Bestandteile unserer modularen Ausstattung erweitert werden.

Aus Erfahrung klug

Innovationen entstehen aus täglicher Arbeit

Unsere tägliche Arbeit mit der Lasertechnologie und Robotik in der Auftragsfertigung und Forschung bringt viele neue Innovationen hervor, welche in den Anlagenbau mit einfließen.

Kundenindividuell

Jede Anlage und jede Laserbearbeitung ist individuell

Wir beraten Sie individuell zu Ihrer Laseranlage oder zur Laserbearbeitung Ihrer Bauteile. Unsere kleinen Teams sind schnell und schlagkräftig und verfügen über viel Erfahrung in der Laserbearbeitung und Anlagenkonstruktion.

Sie wollen mehr über uns erfahren?

Reden wir.

Ob Auftragsfertigung im Bereich Laserhärten und Auftragschweißen, individuelle Laseranlagen oder einfach nur ein Erfahrungsaustausch – unsere Mitarbeiter helfen Ihnen die passende Lösung für Ihre Anliegen zu finden.