Repairing a damaged pinion shaft – economical, precise and sustainable

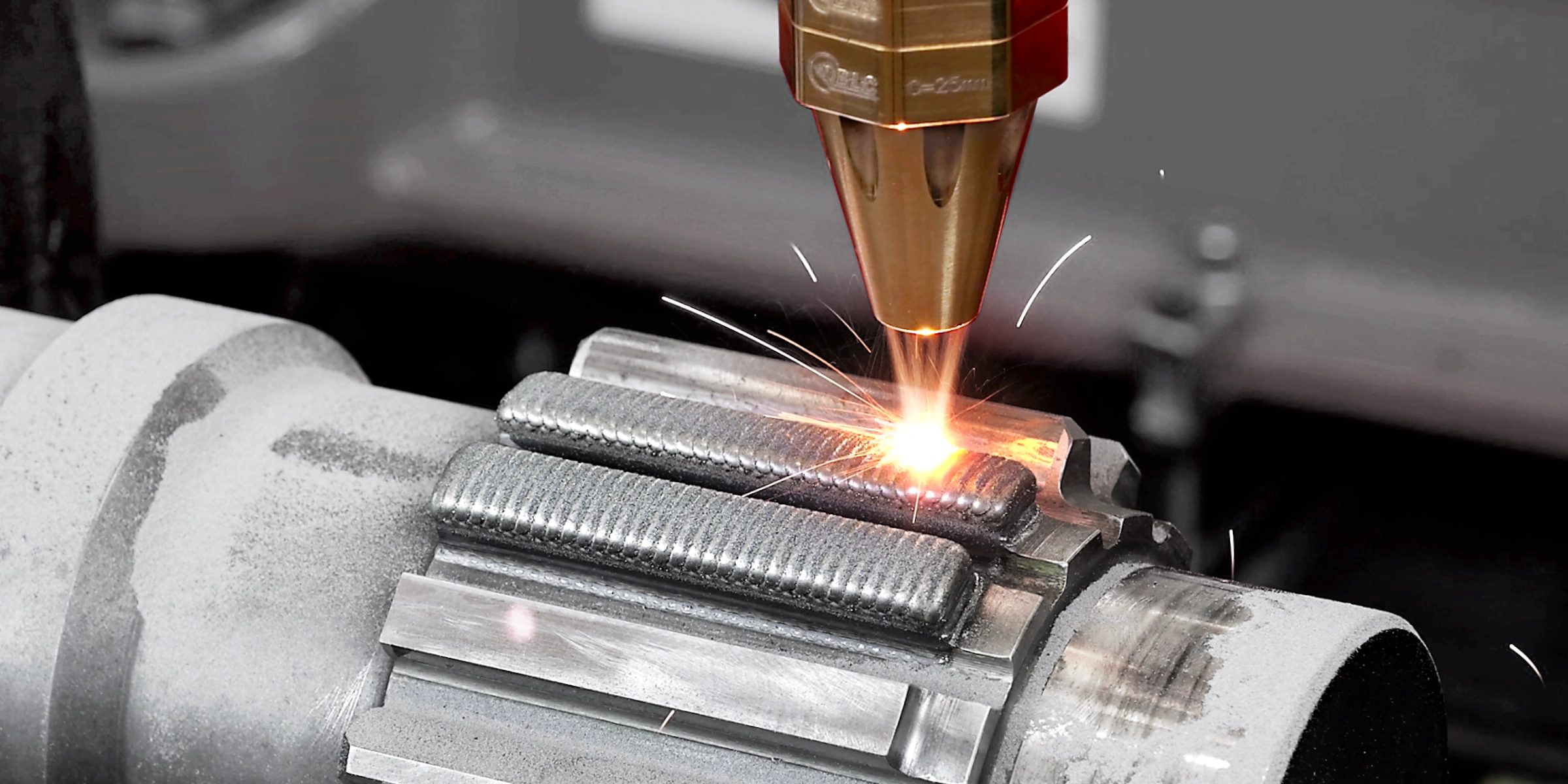

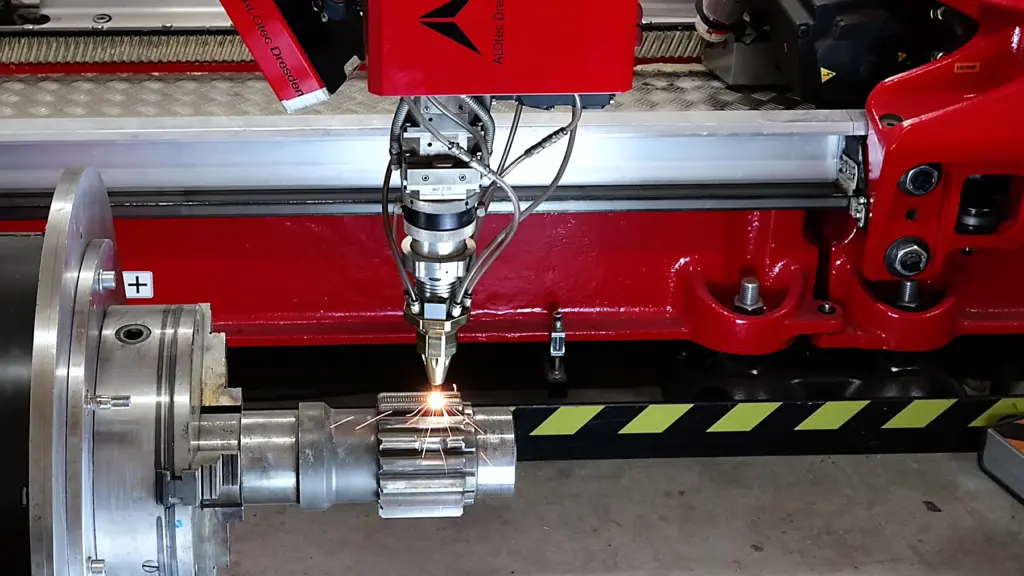

Defective gearing does not necessarily mean replacing entire components. In many cases, a professional repair not only makes technical sense, but is also much more economically efficient. A recent example from our production facility shows how a damaged pinion shaft was repaired using modern laser cladding – with excellent results in terms of load capacity, service life and accuracy of fit.

![]() Overview of the repair process:

Overview of the repair process:

- Preparation: The damaged gearing of the pinion shaft is first milled off precisely. This completely removes any existing cracks, chipping or wear points.

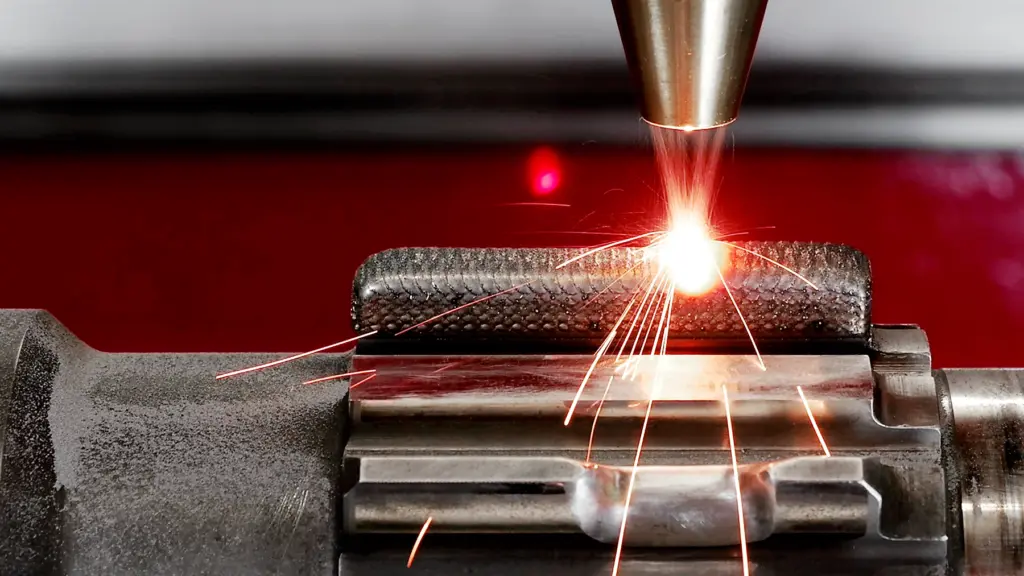

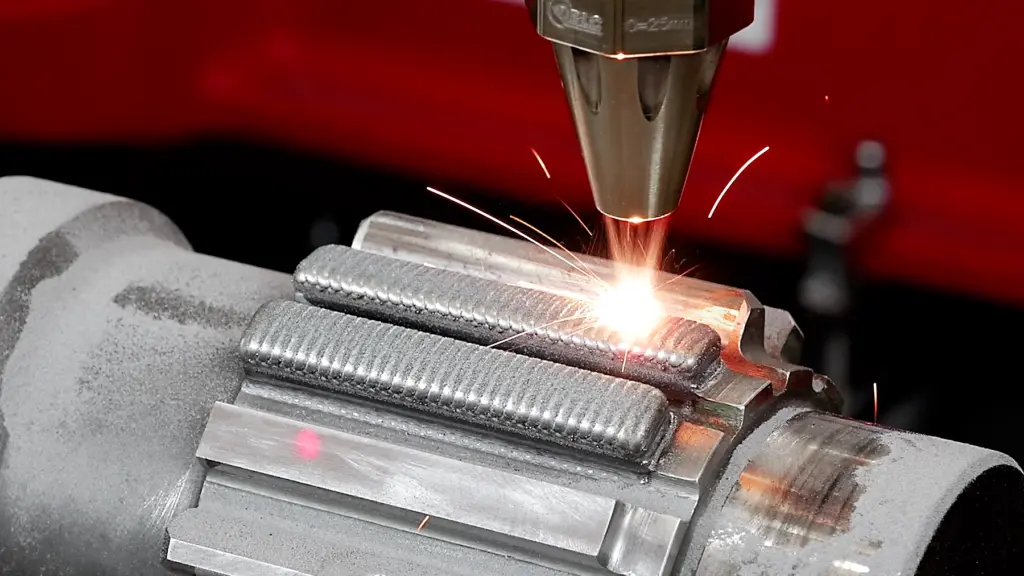

- Cladding: The material is then applied using laser powder cladding. A steel containing FeCrMo was used as the filler material – selected for its high wear resistance and good welding properties.

- Multi-layer structure: The new material is applied in several layers. The welding process follows a meandering pattern that ensures even distribution and excellent adhesion.

- Support contour: A support contour is applied all around for optimization. This stabilizes the application.

- Final processing: After welding, the new toothing is machined to the exact final dimension – with high dimensional accuracy and surface quality.

The result: A fully reconditioned pinion shaft with optimized properties – functional, resilient and ready for use. The expense of new production and long delivery times is eliminated, resources are conserved.

We have created a video about repairing the gearing of a pinion shaft and published it on Youtube:

Summary: Repairing complex components such as gears is a tried-and-tested way of reducing downtimes while acting economically and ecologically. With our laser powder cladding process, we offer precise solutions for sustainable repairs – individually adapted and quality-assured.

ALOtec Dresden – Your partner for repair, wear protection and additive manufacturing.