Laser hardening and cladding

in perfection

Technologies for laser processing

Laser hardening, cladding and additive manufacturing

ALOtec Dresden offers innovative solutions such as laser hardening, laser cladding and additive manufacturing to provide components with long-lasting wear and corrosion protection. With precise cladding, whether powder or wire, we enable efficient repairs and long-lasting coatings. Our additive manufacturing enables the resource-saving and precise production and design modification of complex 3D components, offering maximum flexibility and efficiency.

Laser hardening extends the service life of metallic surfaces through targeted hardness improvement. In addition to repairs, laser cladding also offers excellent wear and corrosion protection as well as design adjustments. Thanks to real-time process control with laser power regulation and thermal imaging camera systems, we achieve high processing quality. Our technologies are energy-efficient and environmentally friendly.

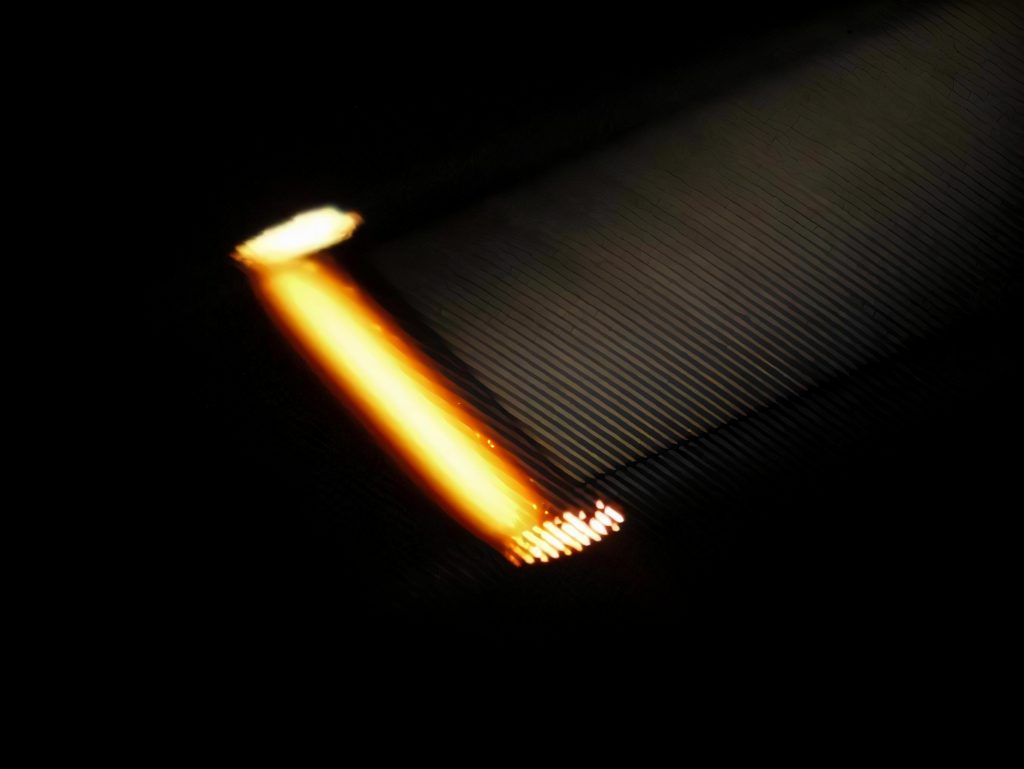

ALOhard

Laser hardening

Our ALOhard laser hardening technology offers a precise and efficient way to increase the wear resistance of metal surfaces.

Laser hardening is a surface hardening process that generates maximum hardness values on the component surface with very low energy input. The advantages speak for themselves: low distortion, no quenching media required, energy-efficient and environmentally friendly.

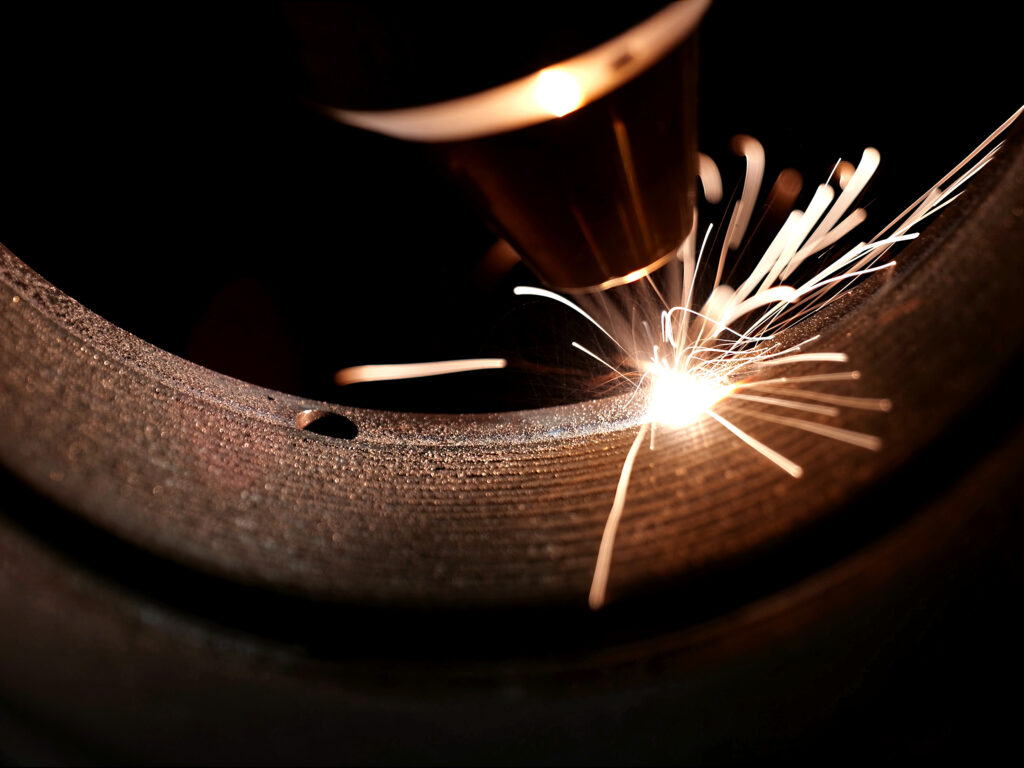

ALOpowder

Cladding with powder

With ALOpowder laser cladding, we can repair and modify components with high precision and strength.

The possible applications are numerous: repair, corrosion and wear protection, design modification and additive manufacturing.

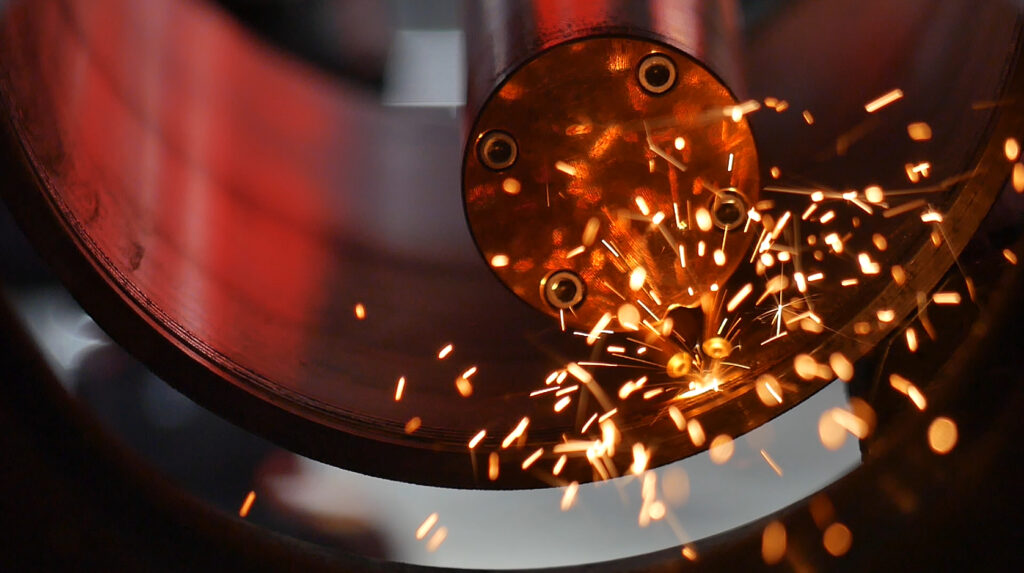

ALOwire

Cladding with wire

With ALOwire laser wire cladding, we can modify and repair components with high precision and strength.

Deposition welding with wire is used for wear protection, repair, design modification and additive manufacturing..

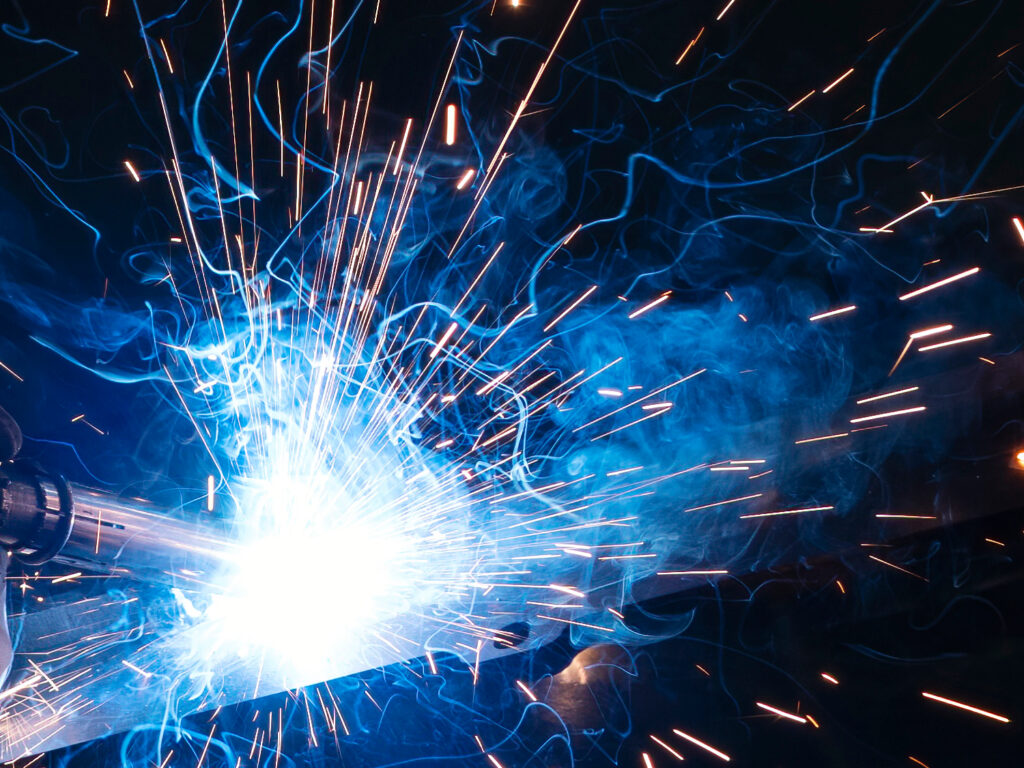

ALOarc

Arc welding

Arc welding is particularly suitable for high deposition rates and is used for coating and joint welding as well as additive manufacturing.

Additive manufacturing makes it possible to produce complex metal structures with maximum precision and strength..

You find our technologies exciting?

Let’s talk.

Find out more about maximum hardness values on highly stressed component surfaces, corrosion and wear protection, repair, design modification or additive manufacturing of 3D components.

Our applications in moving images

Roll it – laser on

Laser hardening

Laser powder cladding

Laser wire cladding