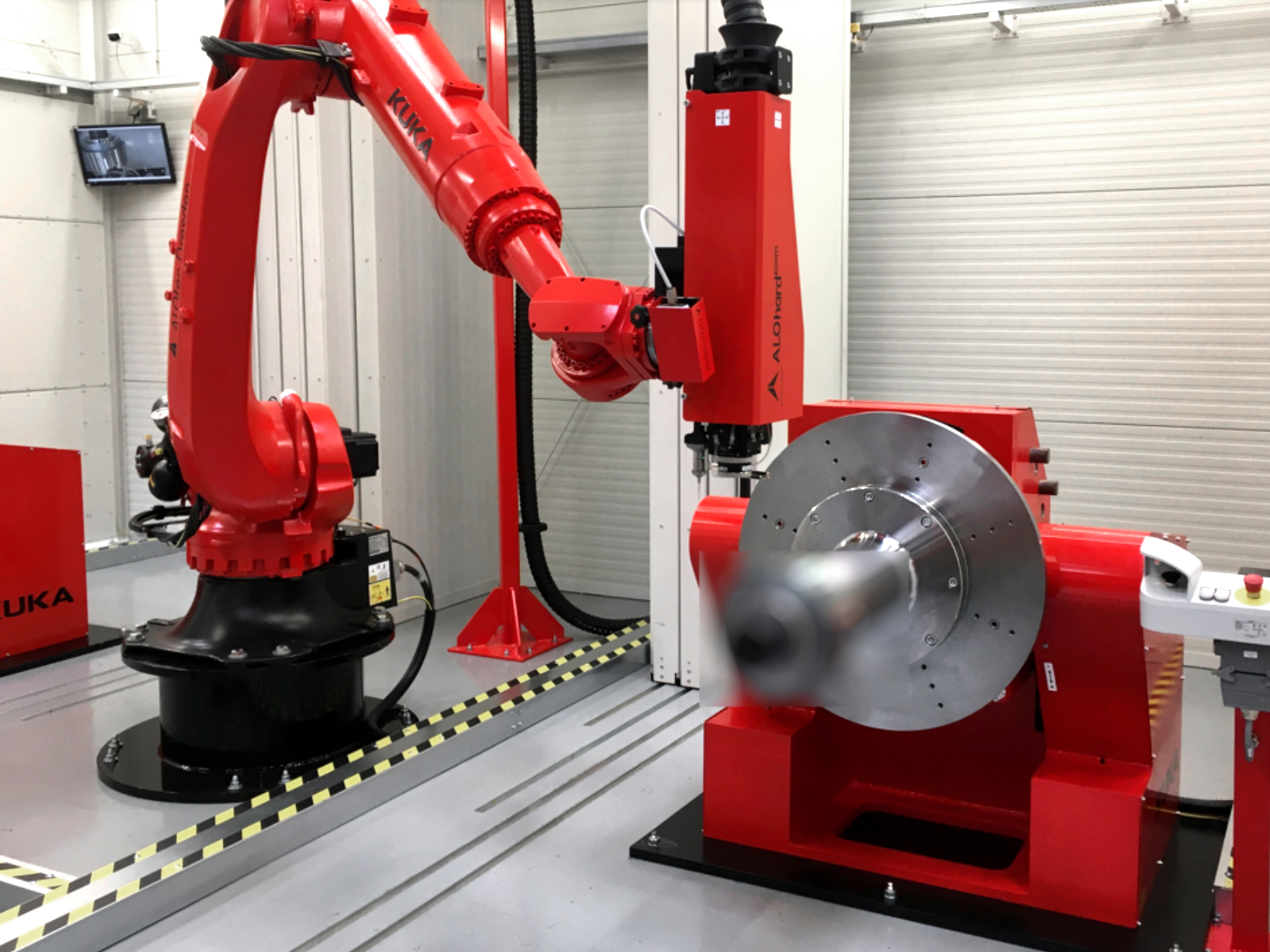

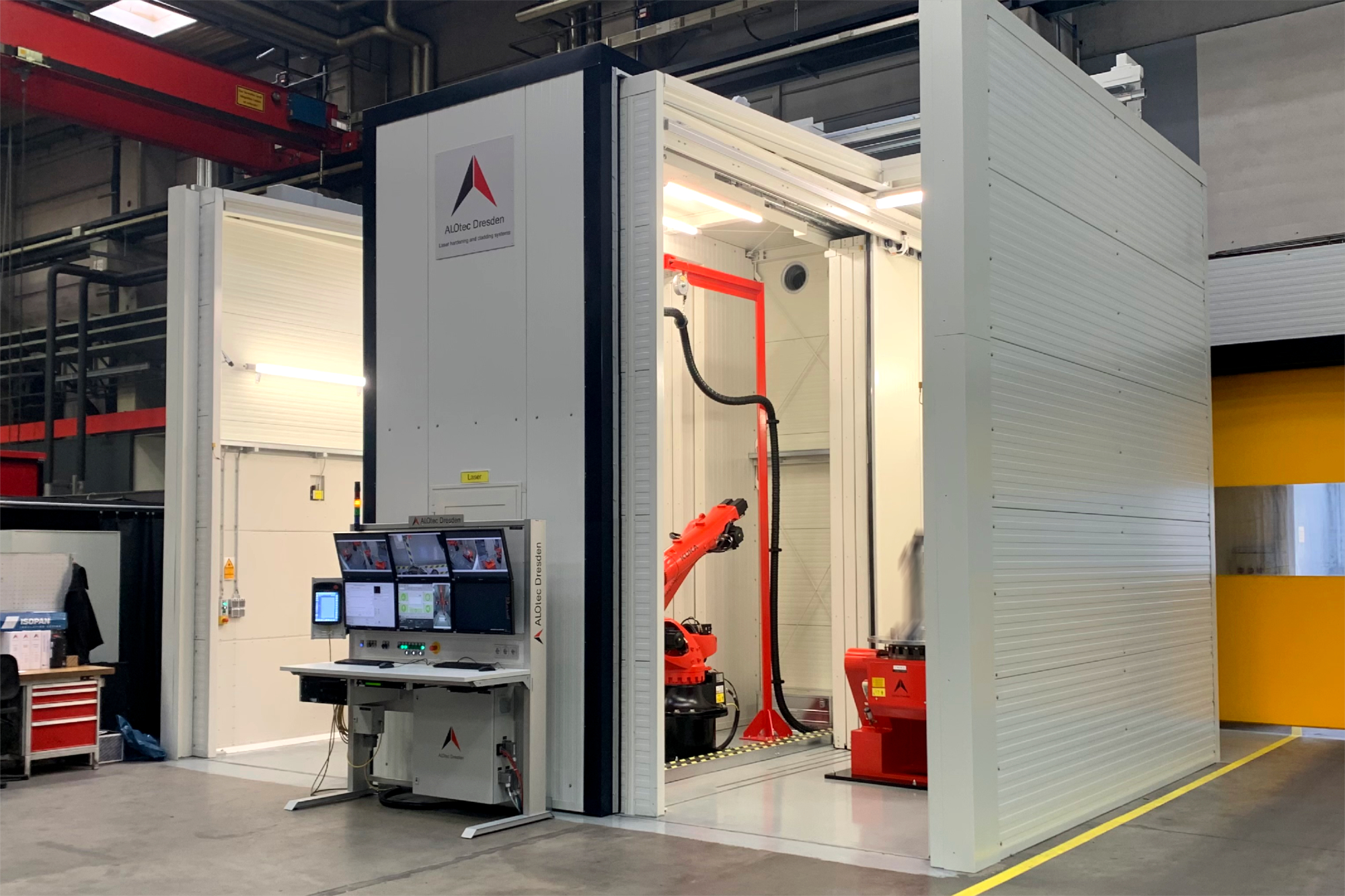

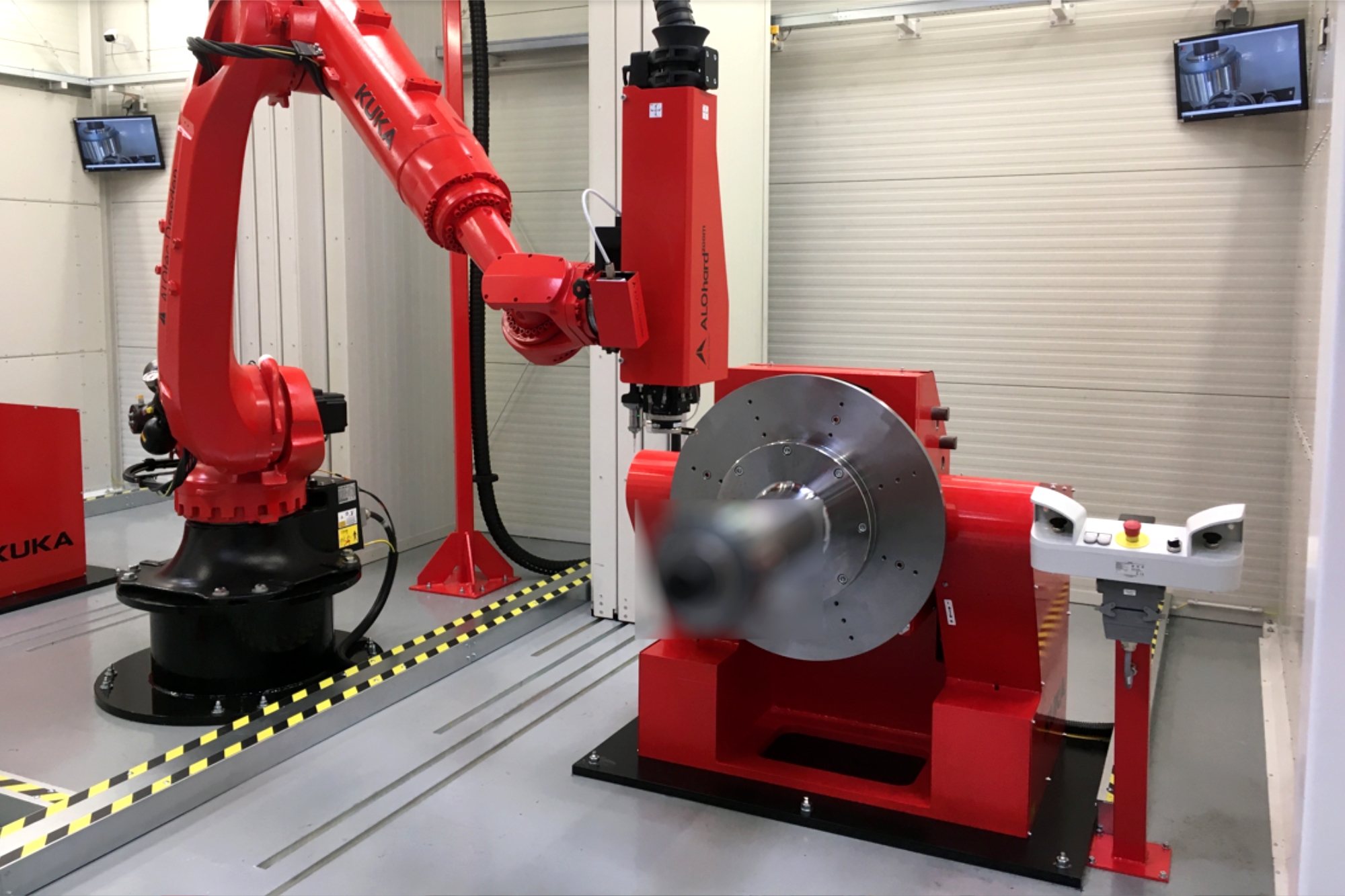

Robot system for laser hardening with turn/tilt table and turn table.

Switzerland · Egerkingen

Härterei Gerster AG

Precise and powerful

ALOstation

ALOstation

Stationary laser systems

We offer our customers state-of-the-art system integration for the optimum processing of components, characterised by high performance and flexibility.

Our stationary laser processing systems are customised and fabricated according to the customer’s requirements and needs. These systems have been proving their worth in laser-assisted surface processing for over 25 years.

Straightforward and efficient

The ALOstation concept

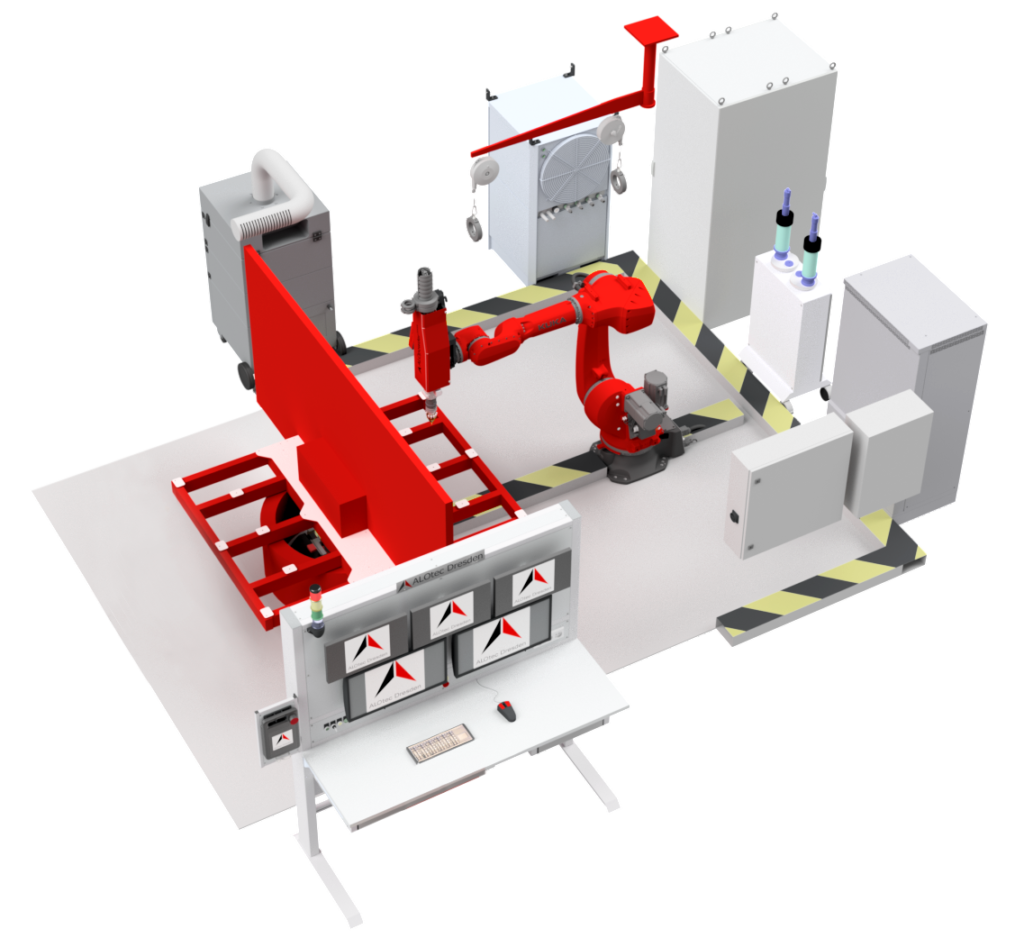

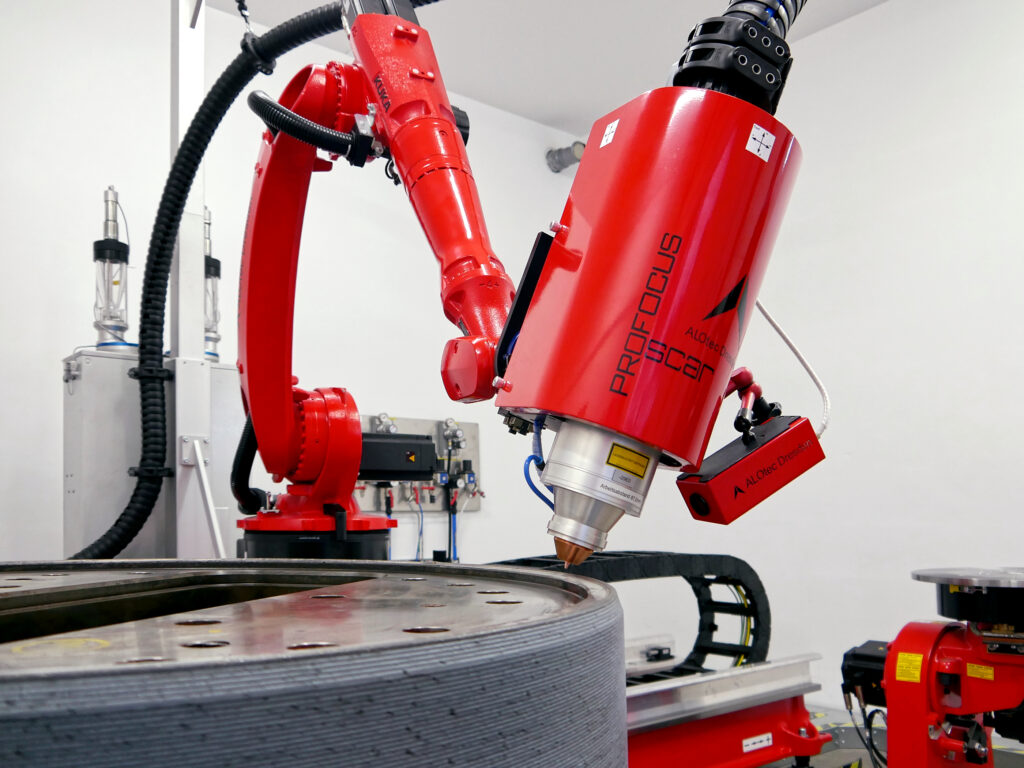

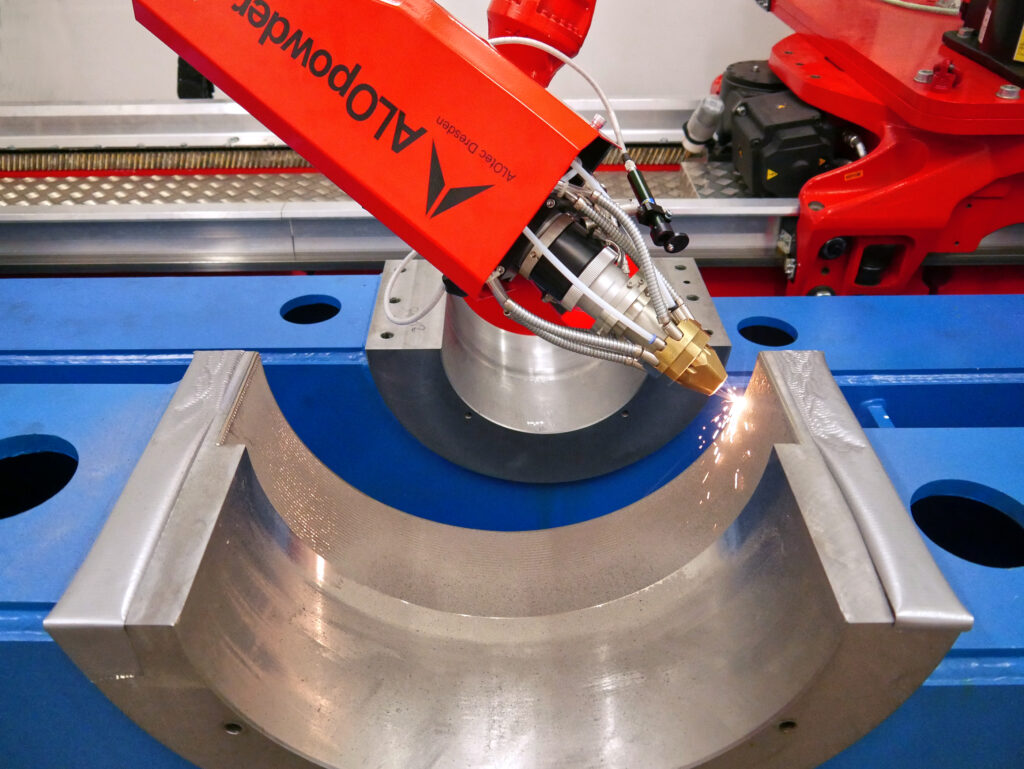

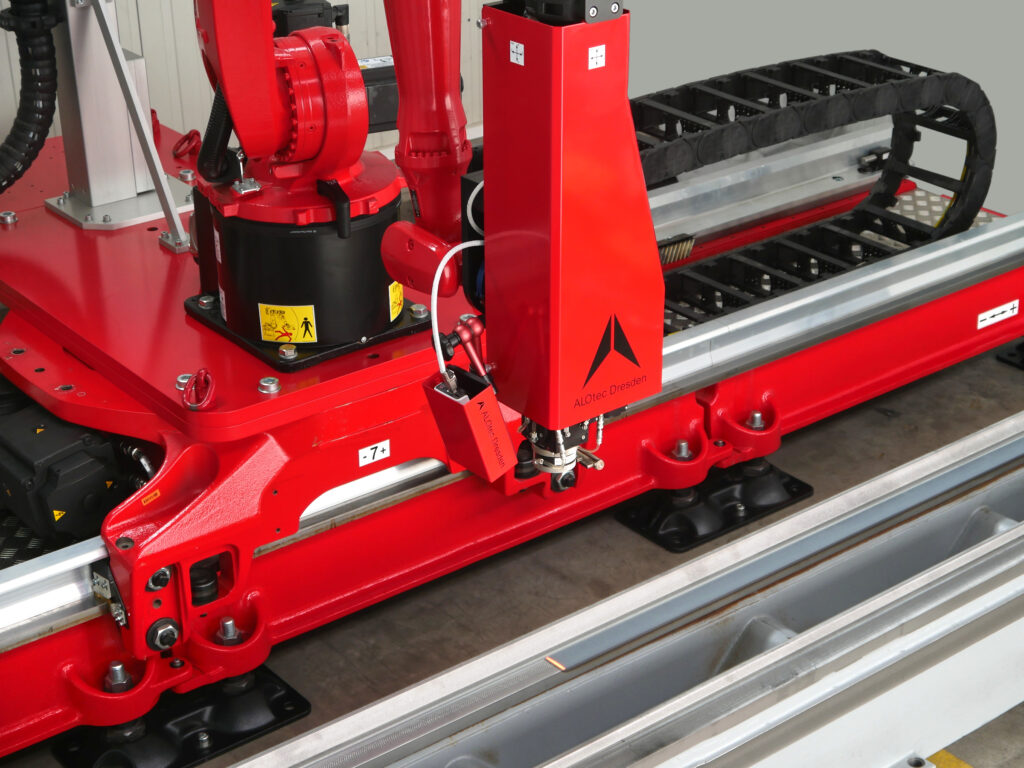

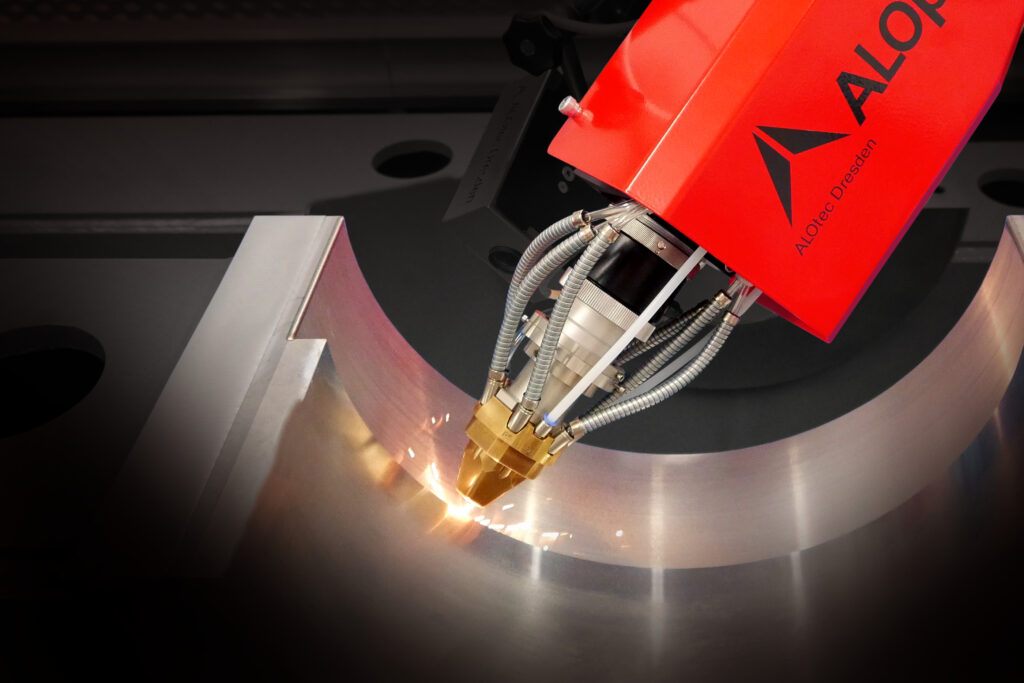

The ALOstation is a stationary robot system for the precise surface processing of components. It combines the technologies of laser hardening, laser cladding with powder or wire as well as arc welding (CMT welding). It is based on a high-quality industrial robot with 6 synchronised axes, which can be expanded to up to 16 synchronised axes using modular components such as a linear unit or turn/tilt table. The surfaces are processed using high-precision processing heads and a fibre-coupled high-performance diode laser with an output power of up to 45 kW. The technology can be changed swiftly and easily thanks to our quickcoupler system.

Operation of the ALOstation is simple and straightforward thanks to predefined macros (programming assistant) and laser power control using the E-MAqS thermal imaging camera and LompocPro control system.

ALOstation – we build your system according to your needs!

ALOstation laser system

Versatile use

In addition to the possible applications for surface hardening, repair and cladding as well as welding and additive manufacturing, the ALOstation impresses with a fast and smooth technology change using a quickcouple system, up to 16 synchronised axes and user-friendly operation and control.

Laser hardening Arc welding

Laser cladding with powder and wire

Quick and easy technology change

Technology in stationary operation

Wide range of applications

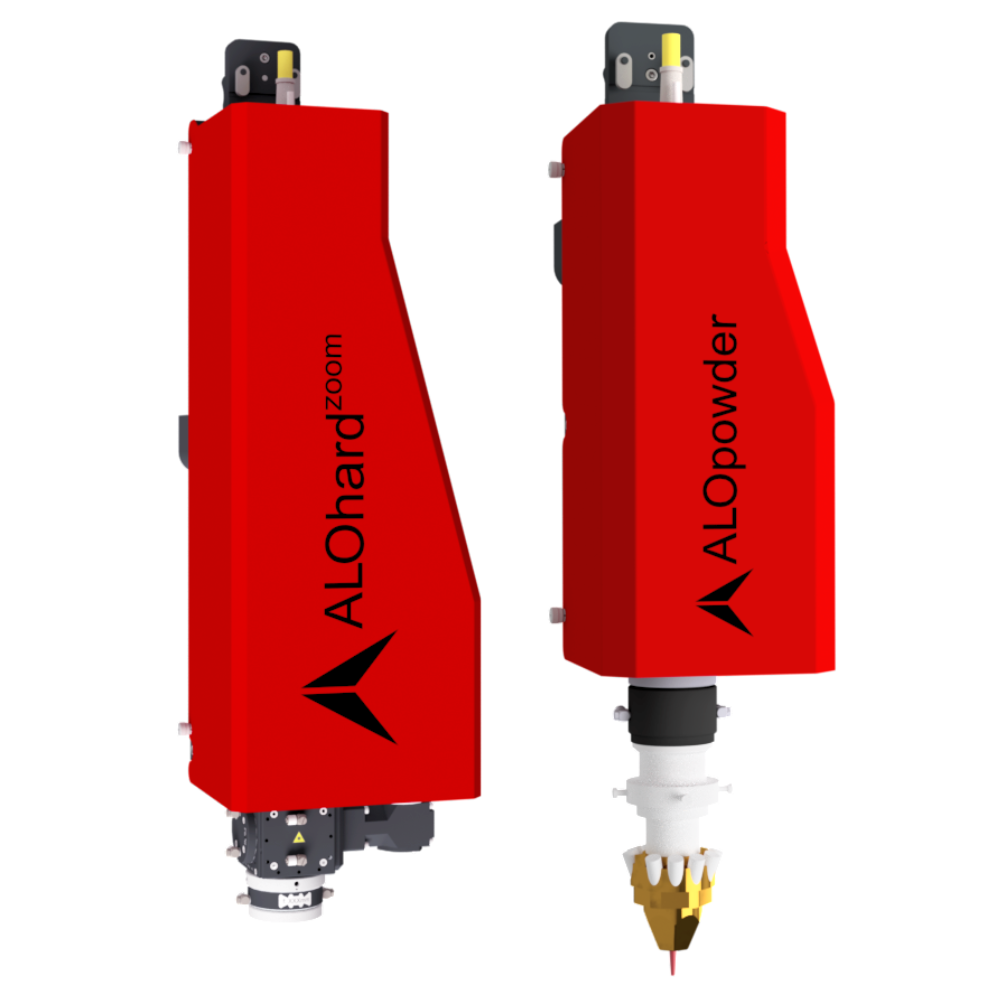

![]() Laser hardening ALOhard with fixed and variable laser track width and dynamic scanning optics, laser powder cladding ALOpowder with fixed and variable laser track width as well as internal cladding, laser wire cladding ALOwire and CMT welding ALOarc in mould and tool making and mechanical engineering

Laser hardening ALOhard with fixed and variable laser track width and dynamic scanning optics, laser powder cladding ALOpowder with fixed and variable laser track width as well as internal cladding, laser wire cladding ALOwire and CMT welding ALOarc in mould and tool making and mechanical engineering

![]() Specific hardening of metallic surfaces and repair or reconditioning of highly stressed component surfaces, cladding and additive manufacturing

Specific hardening of metallic surfaces and repair or reconditioning of highly stressed component surfaces, cladding and additive manufacturing

![]() Suitable for processing forming tools, machine parts, cutting tools or screw conveyors, bearing seats, rollers and much more

Suitable for processing forming tools, machine parts, cutting tools or screw conveyors, bearing seats, rollers and much more

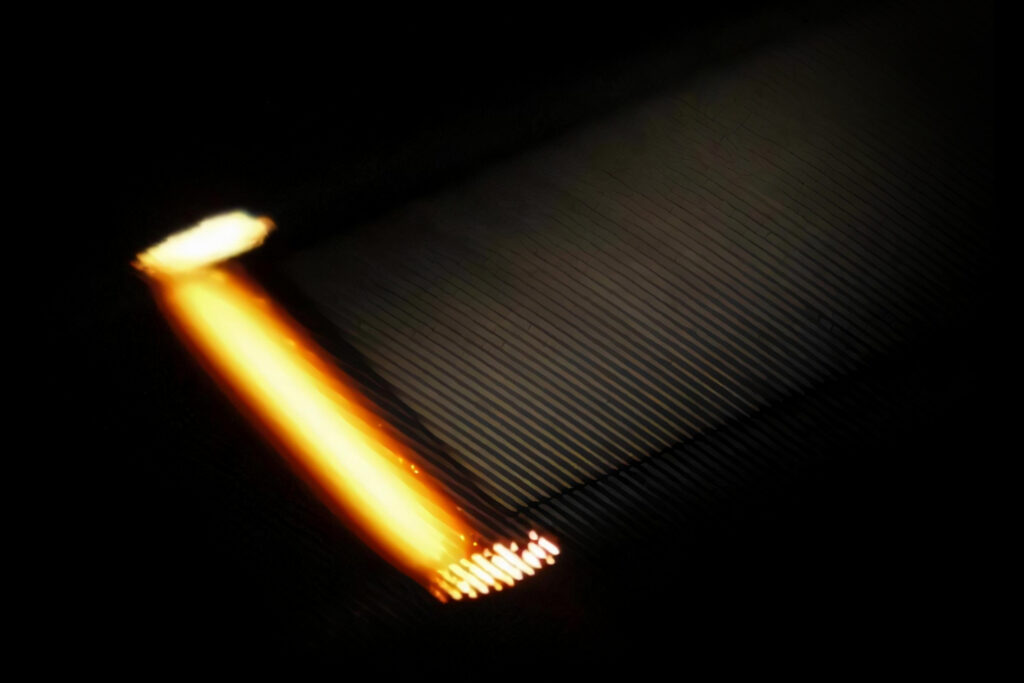

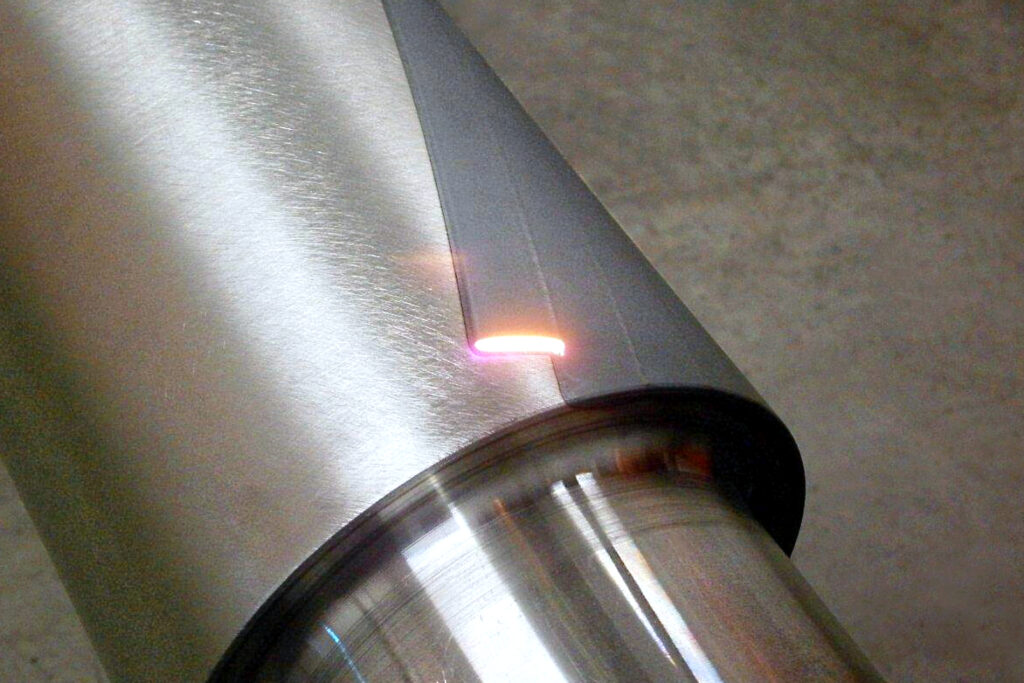

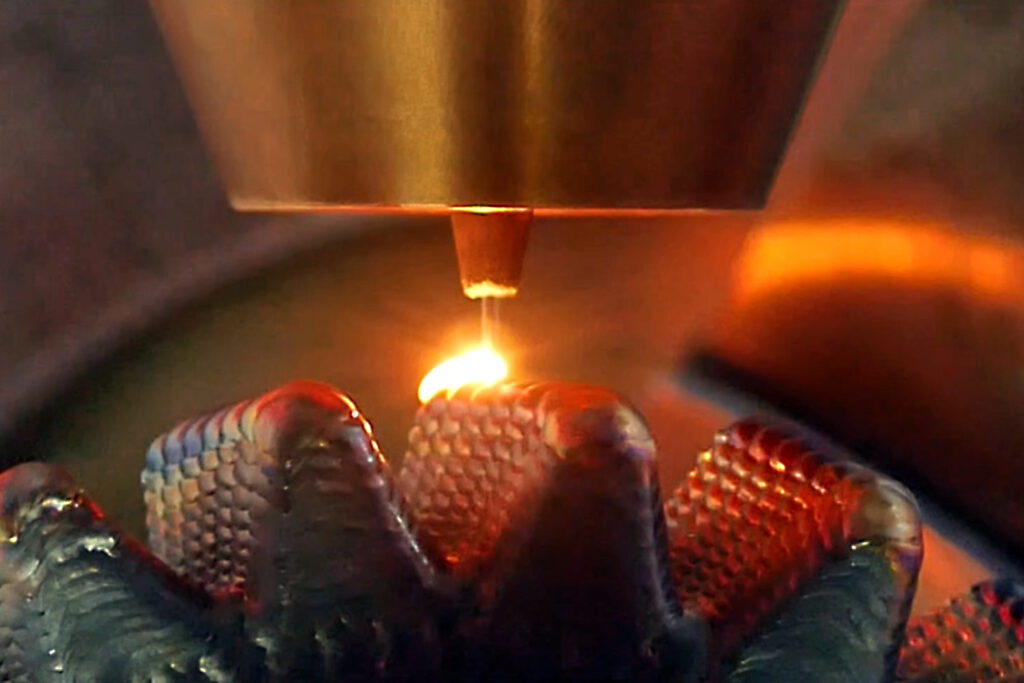

Laser hardening

with fixed and variable laser track widths

Laser cladding

with powder

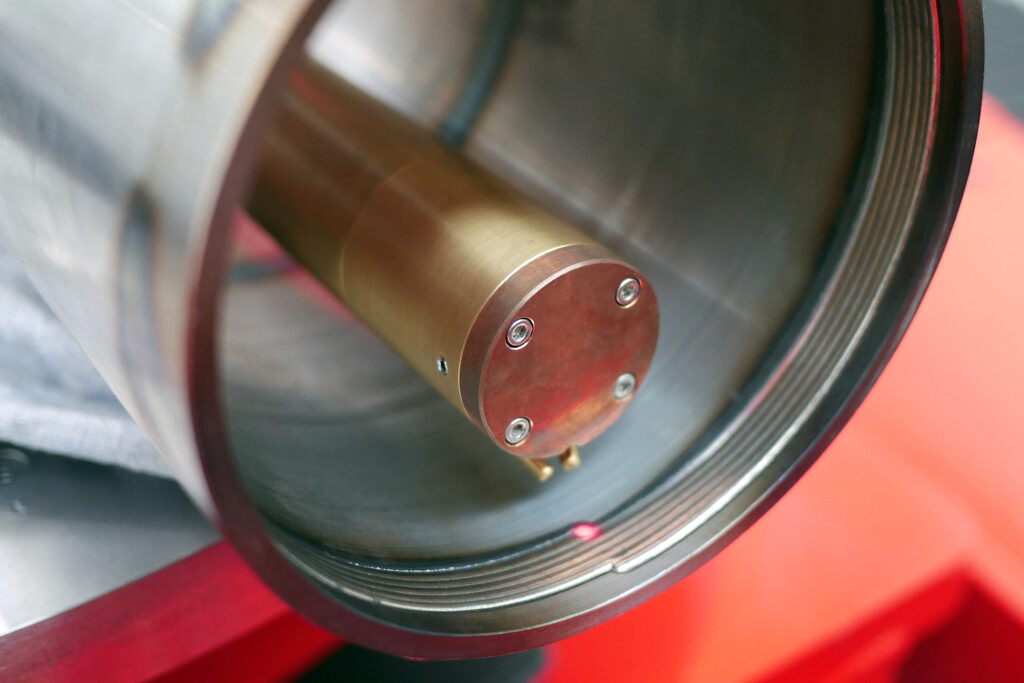

Laser cladding

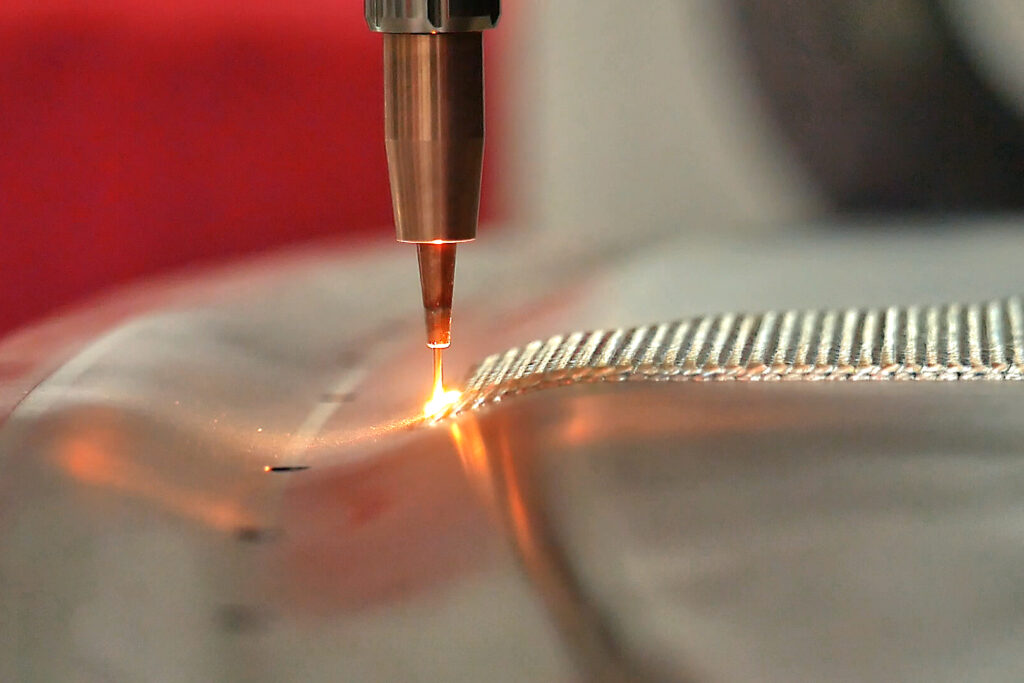

with wire

Arc welding

CMT welding with ALOarc

System engineering

Around the world

-

System for laser hardening

-

System for laser hardening

Setting up the laser system for hardening.

Switzerland · Egerkingen

Härterei Gerster AG -

System for laser hardening

Construction of the robot system for laser hardening.

Switzerland · Egerkingen

Härterei Gerster AG -

System for laser hardening

Handover of the robot system for laser hardening to Härterei Gerster AG in Egerkingen, Switzerland.

Switzerland · Egerkingen

Härterei Gerster AG -

System for laser hardening

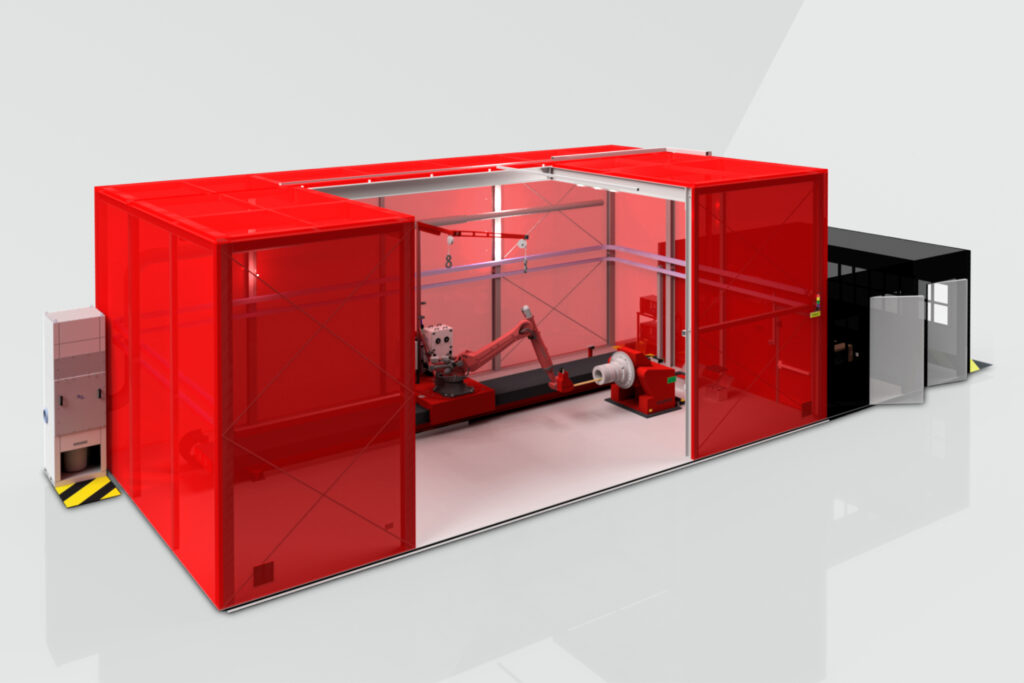

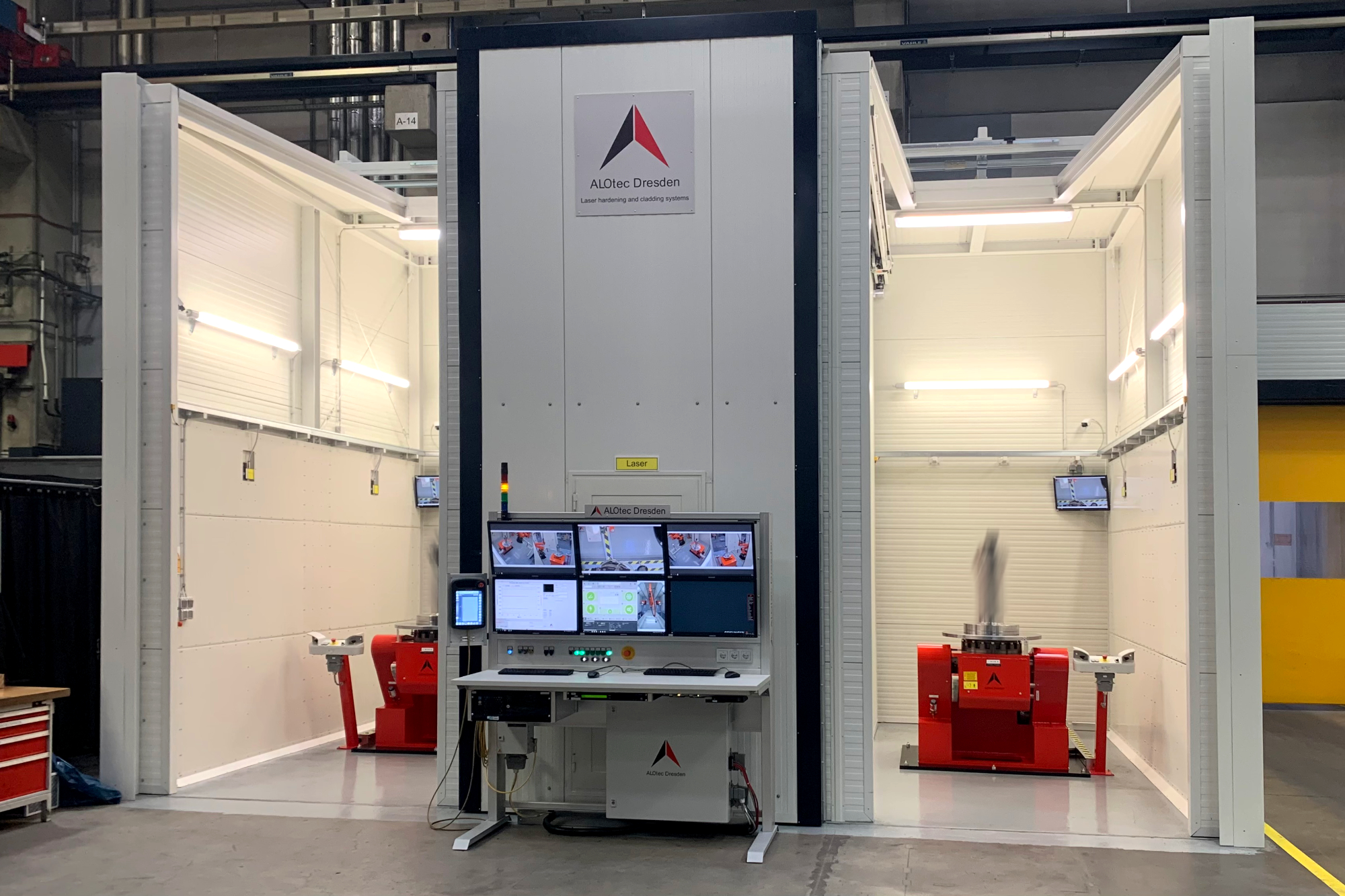

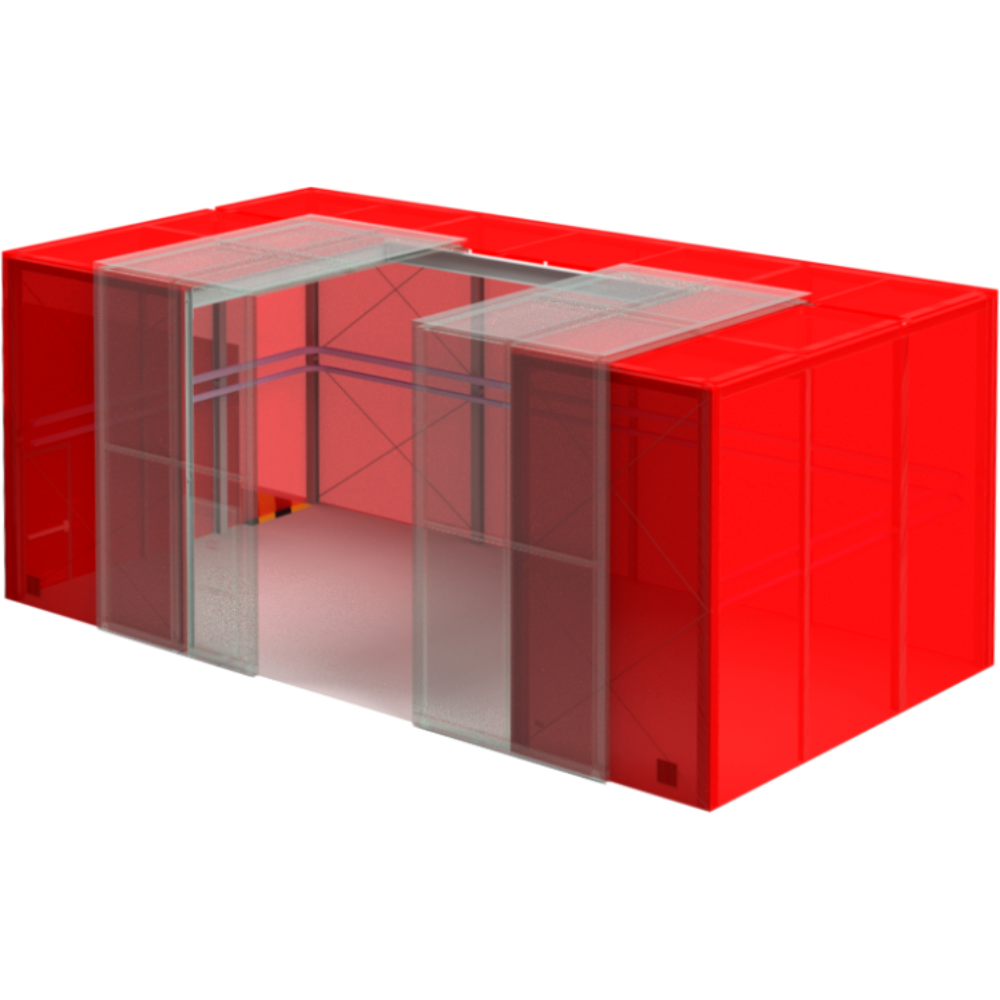

Laser system for hardening with 2 turn-tilt axes in separate laser chambers for increased efficiency and profitability.

Austria

-

System for laser hardening

Laser system for laser hardening with 2 turn-tilt axes in separate laser chambers for increased efficiency and profitability.

Austria

-

System for laser hardening

Robot system for laser hardening with 2 turn-tilt axes in separate laser chambers for increased efficiency and profitability.

Austria

-

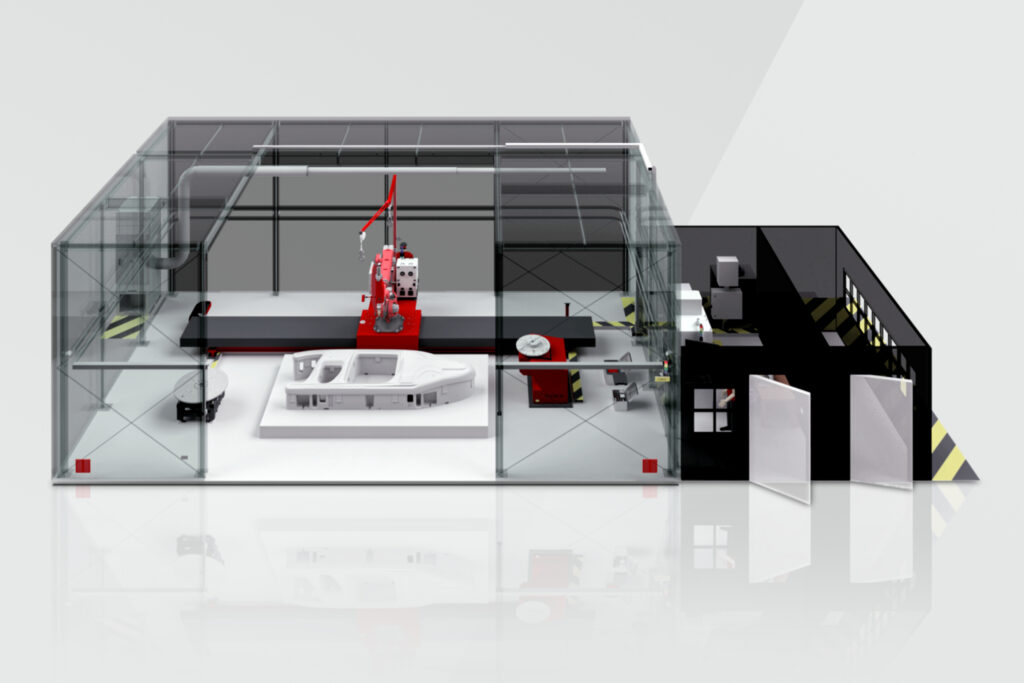

System for laser cladding

System for laser powder cladding for external and internal coating including turn/tilt table with 2 axes for part positioning.

Belgium · Waregem

Gearcraft Vanhoutte -

Robot system for laser cladding

Robot system for laser cladding with powder for external and internal coating including turn/tilt table with 2 axes for part positioning.

Belgium · Waregem

Gearcraft Vanhoutte

Stationary laser processing

Advantages of the ALOstation

Scalable systems and modules

Customised design – according to your requirements

Up to 16 synchronised axes

when used on a linear unit and turn/tilt table

Fast technology changeover

with the ALOtec quickcouple system

Continuous documentation

of process parameters and laser power

State-of-the-art technology

thanks to in-house research and contract manufacturing

Maximum laser power

Up to 45 kW laser power possible

Simple system operation

Straightforward operation thanks to predefined programme sequences

Offline programming

via CAD/CAM and geometry scan for path planning

Reliable service and support

Worldwide maintenance, system updates and training

Modular system

Technical equipment

We design and manufacture your customised, stationary laser system for hardening, cladding with powder and wire or for CMT welding.

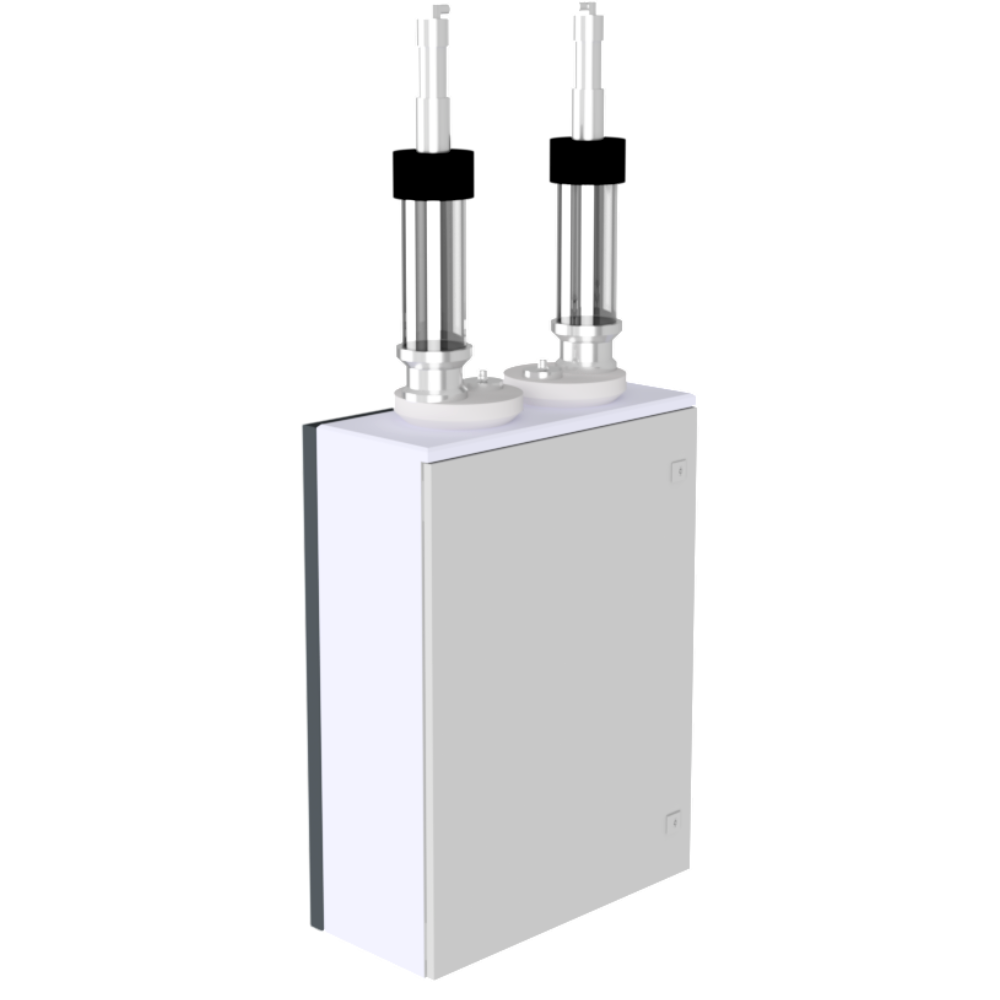

Connections

Electricity / Compressed air / Gas

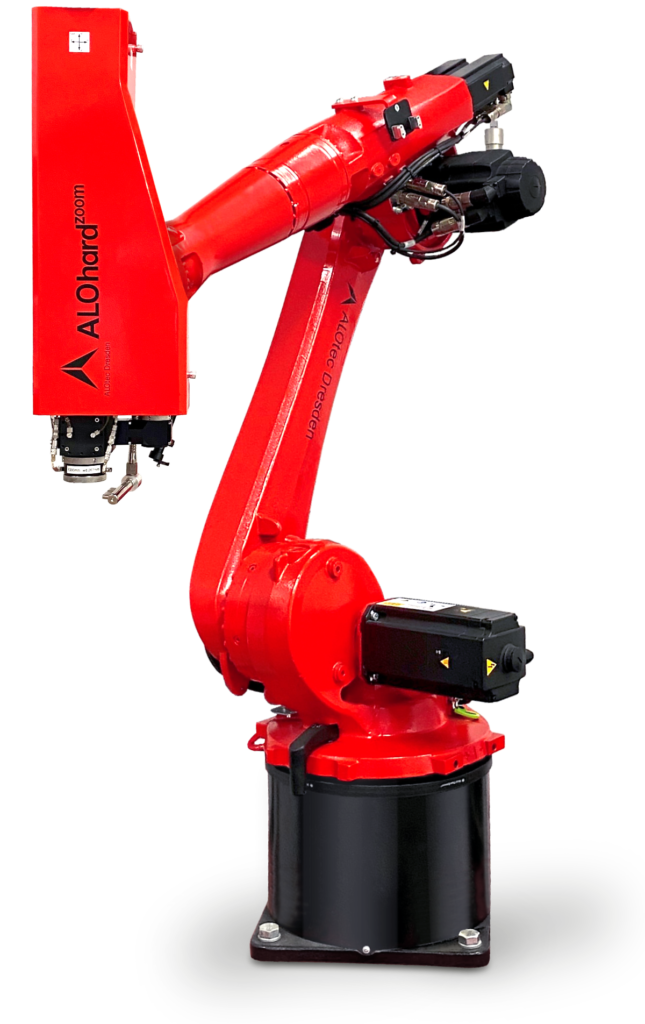

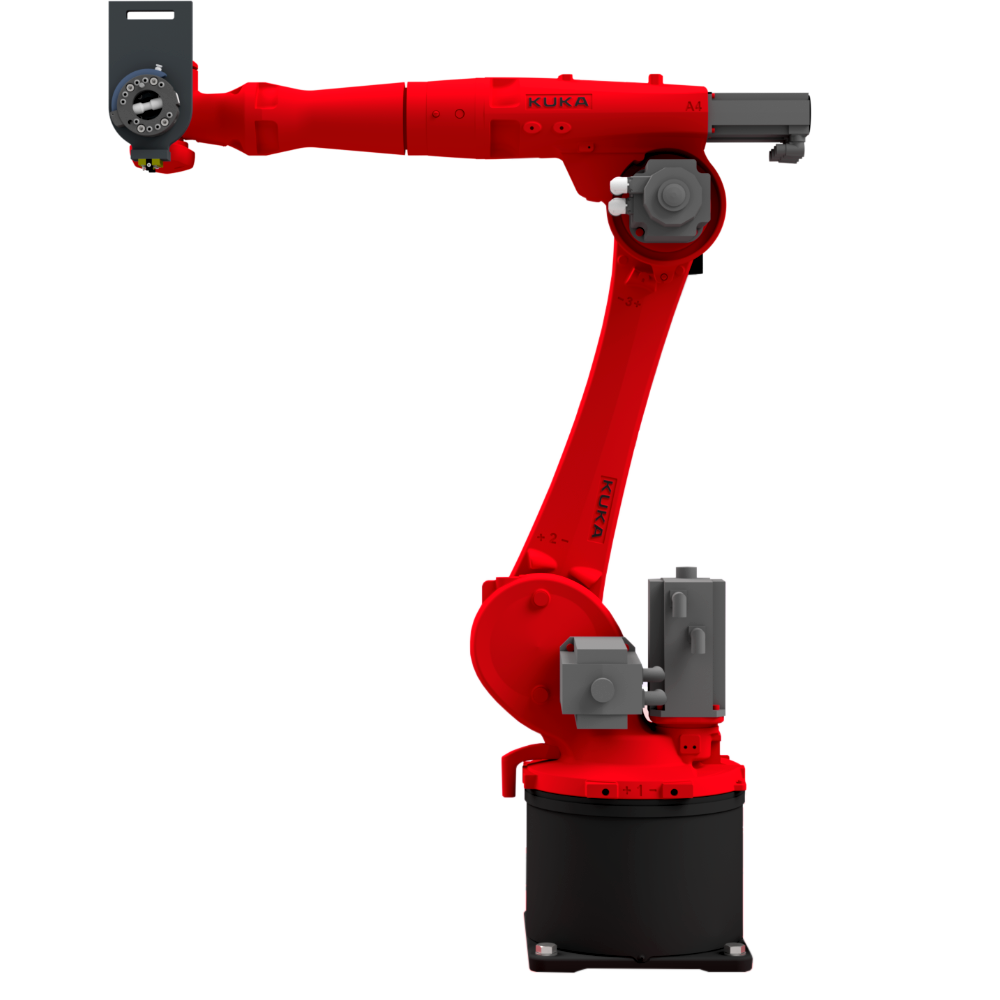

Robot

Axes / Reach / Payload

Laser

Power

Optics

Hardening / Cladding / CMT welding

Peripherals

Positioner and linear unit

Add ‑ on

Auxiliary and additional devices

Software

Auxiliary and additional devices

Customised equipment

System modules

Processing optics for laser hardening and cladding

6-axis robot for 3D laser beam movement

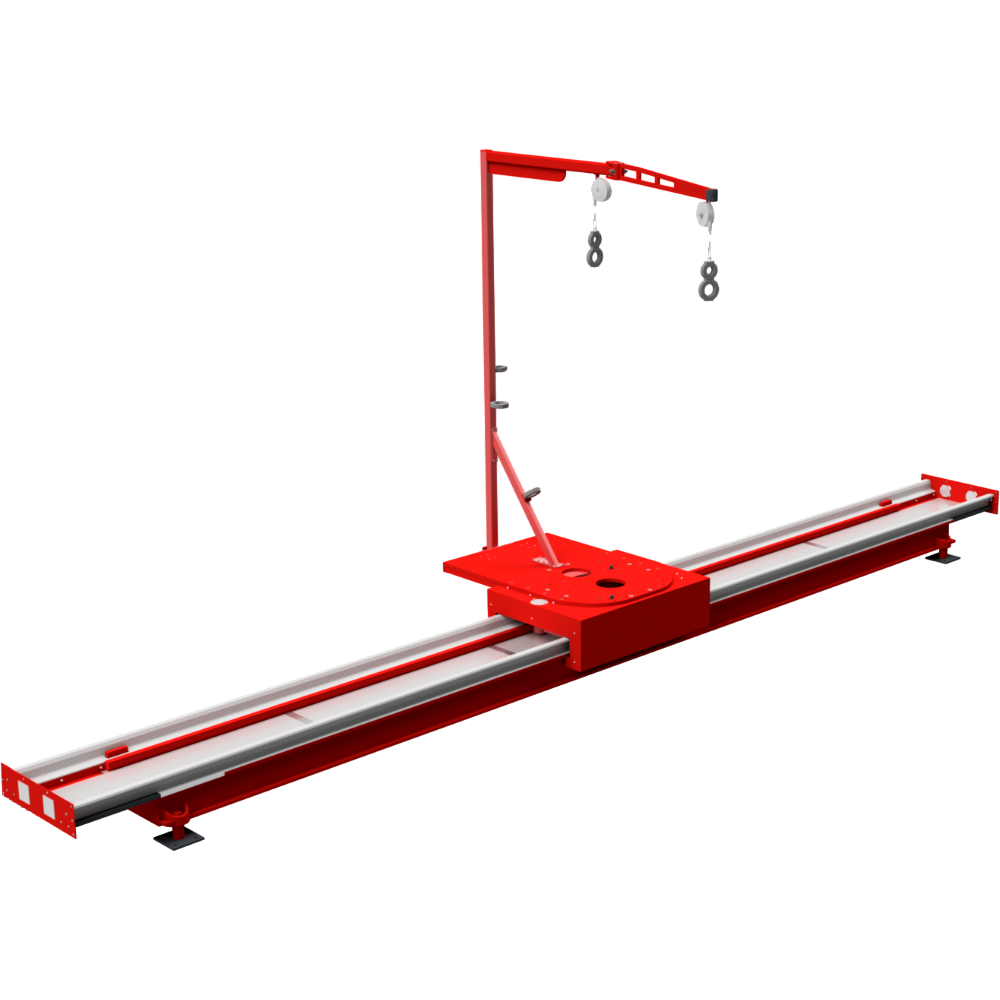

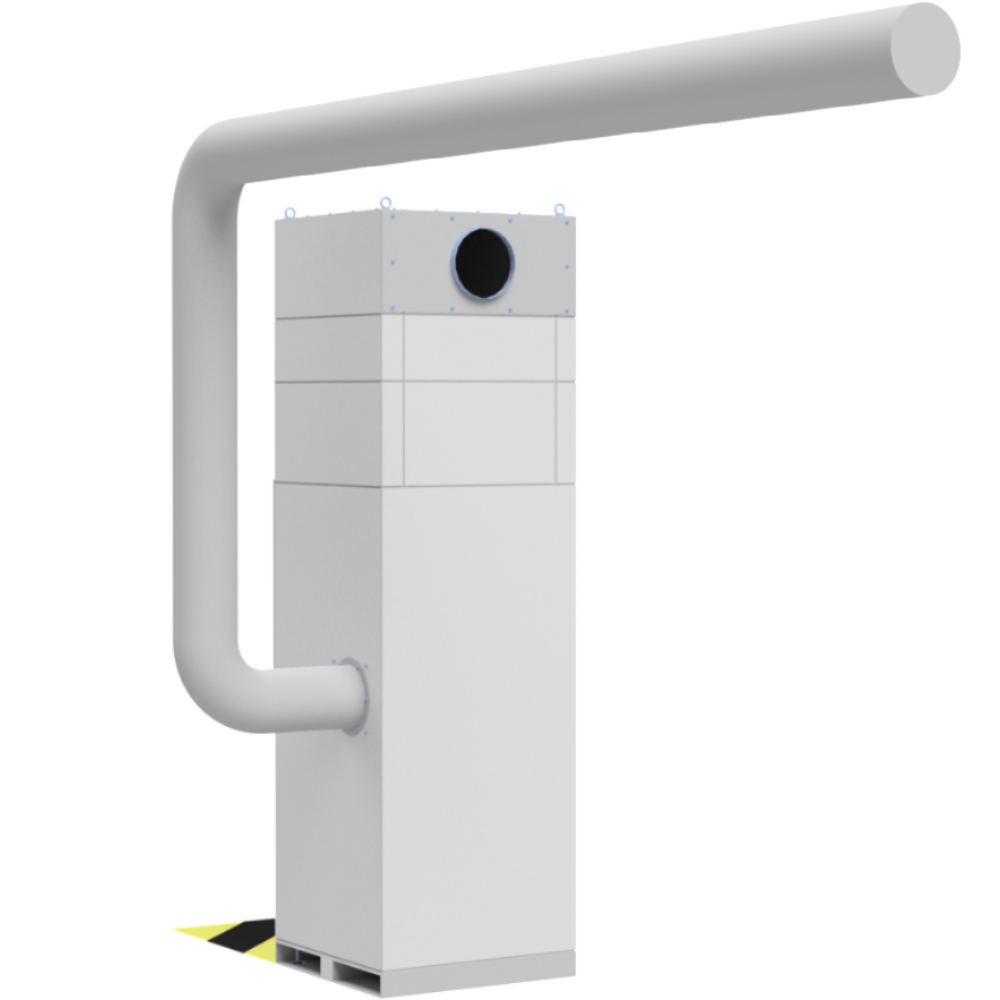

Linear unit for stationary use

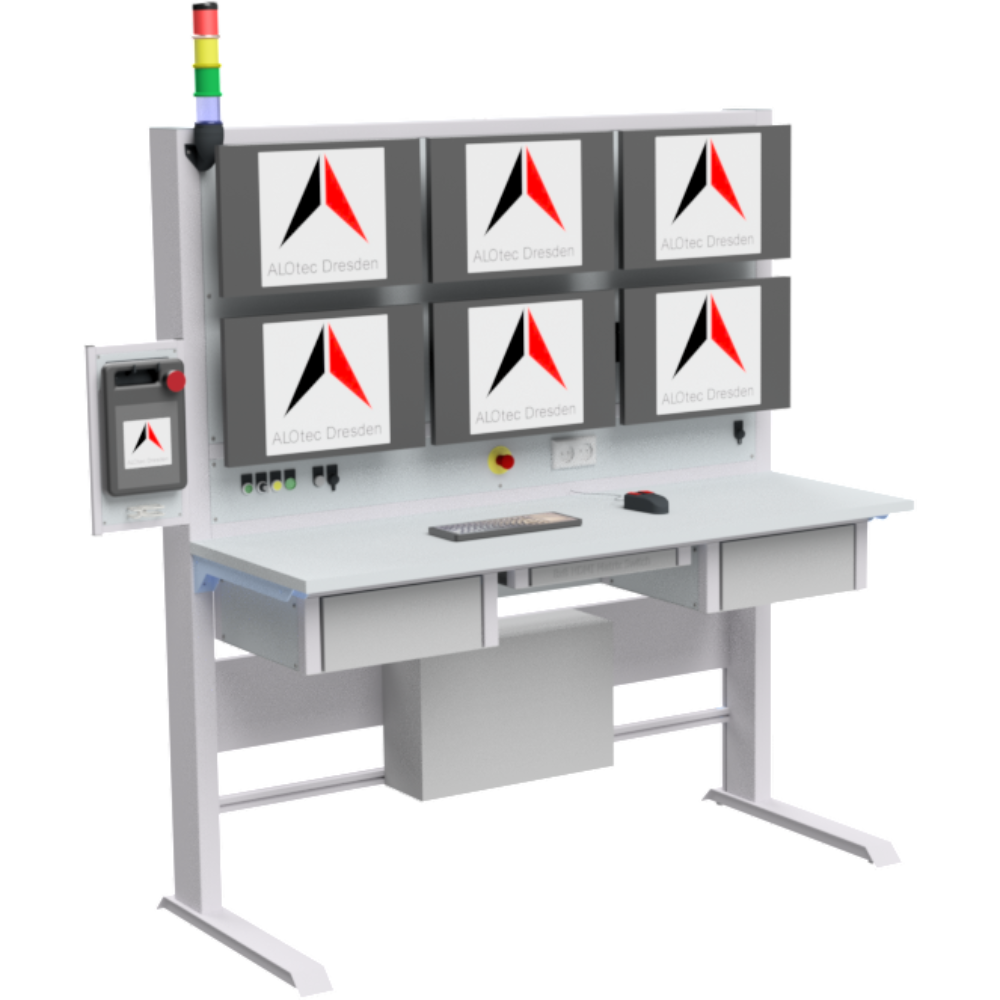

Control station for stationary systems

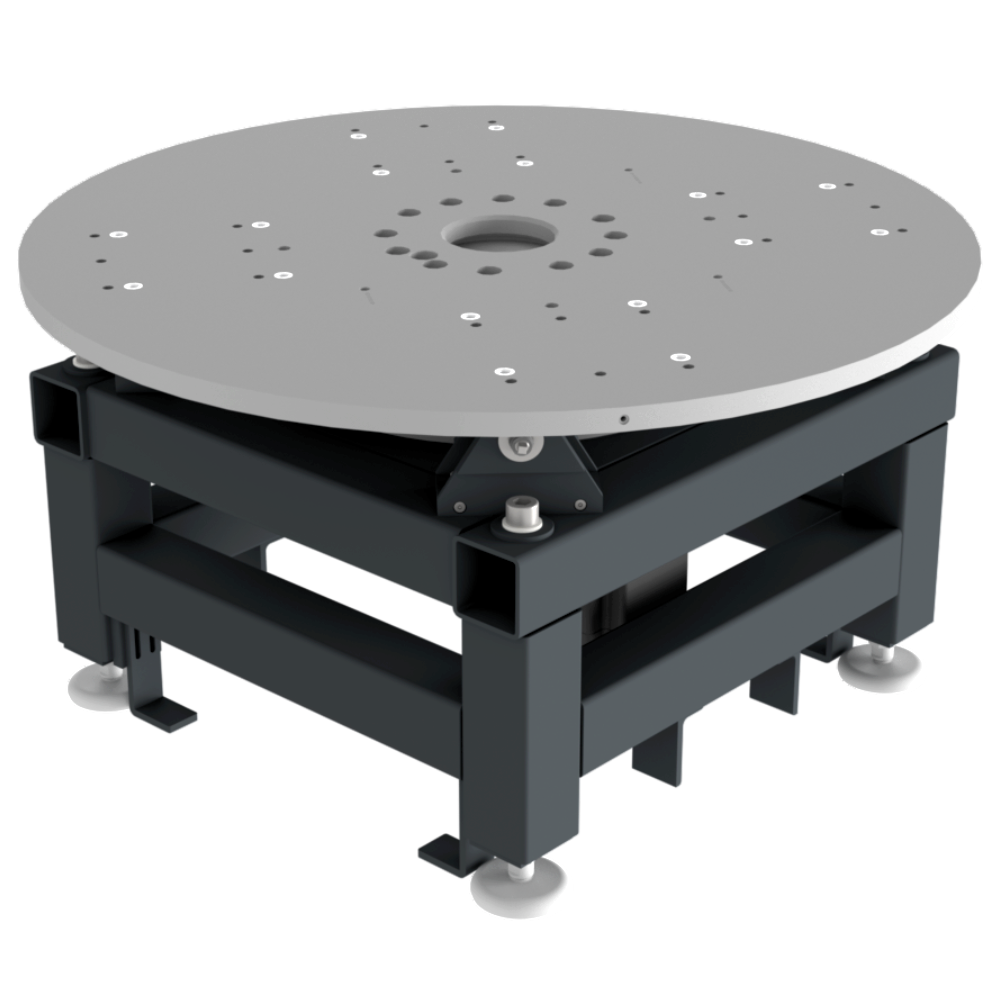

Turn/tilt table with 1 and 2 axes for positioning

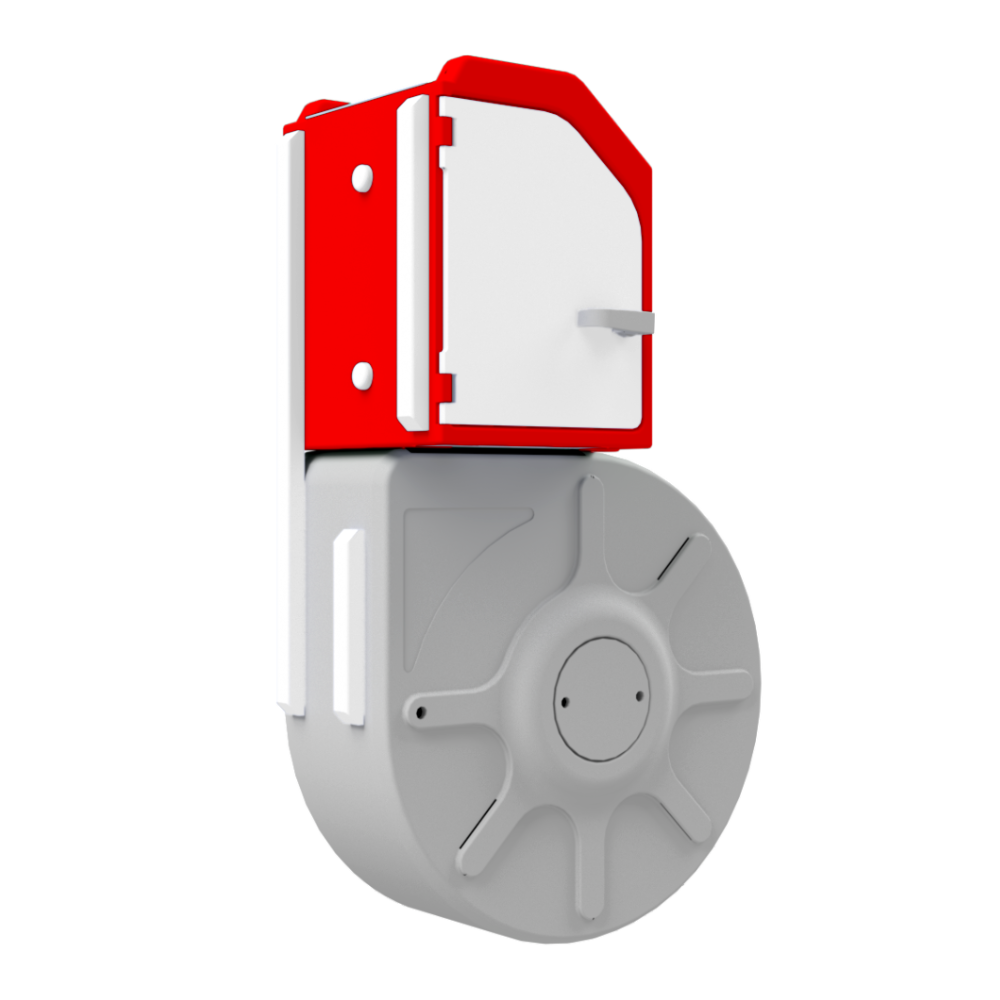

Rotary table with 1 axis for positioning

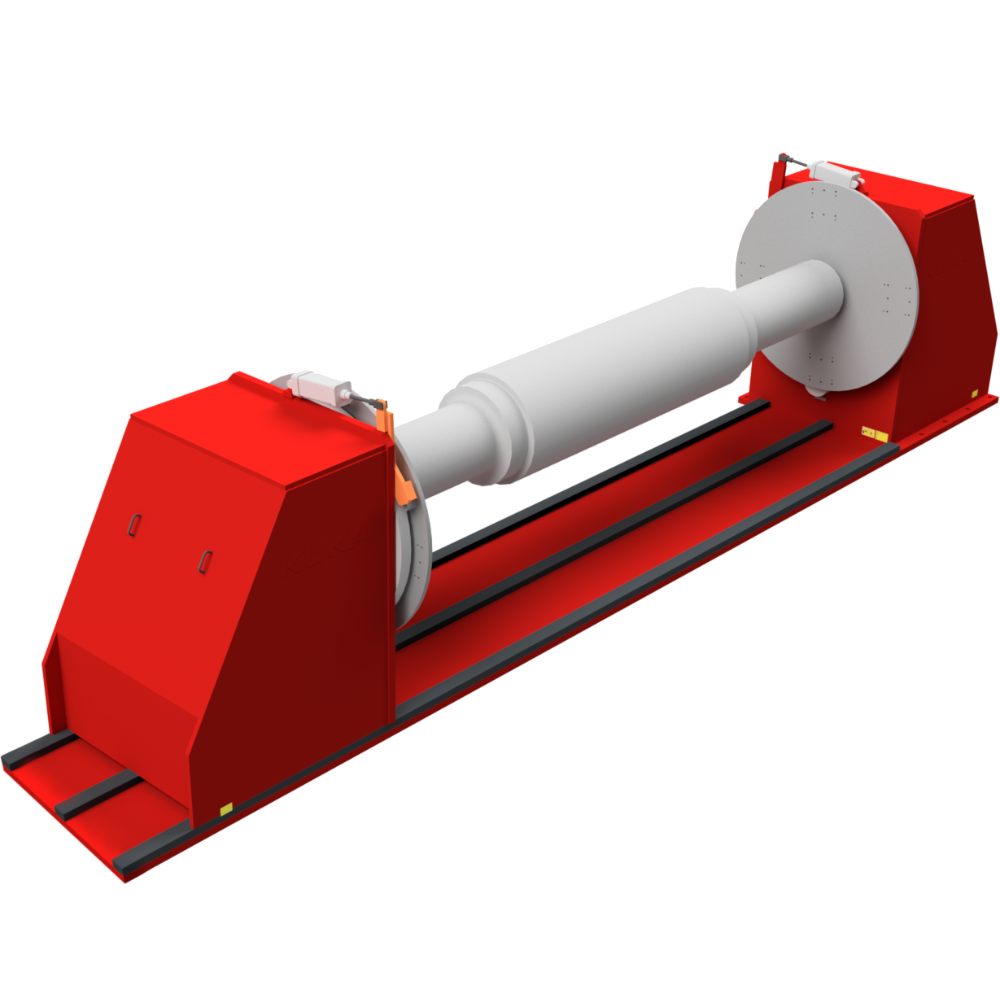

Rotary module with variable steady rest

Modules and accessories such as powder feeder

Modules and accessories such as wire feeder

Laser module with up to 45 kW laser power

Exhaust and cabin exhaust

Laser protection concept with customised safety cabins

Looking for a stationary system with straightforward operation?

Let’s talk.

The ALOstation laser system is designed for a wide range of applications and is modularly expandable. Operation is simple and pre-installed programme sequences guide you quickly and safely through the processes.

Our laser systems in the moving picture