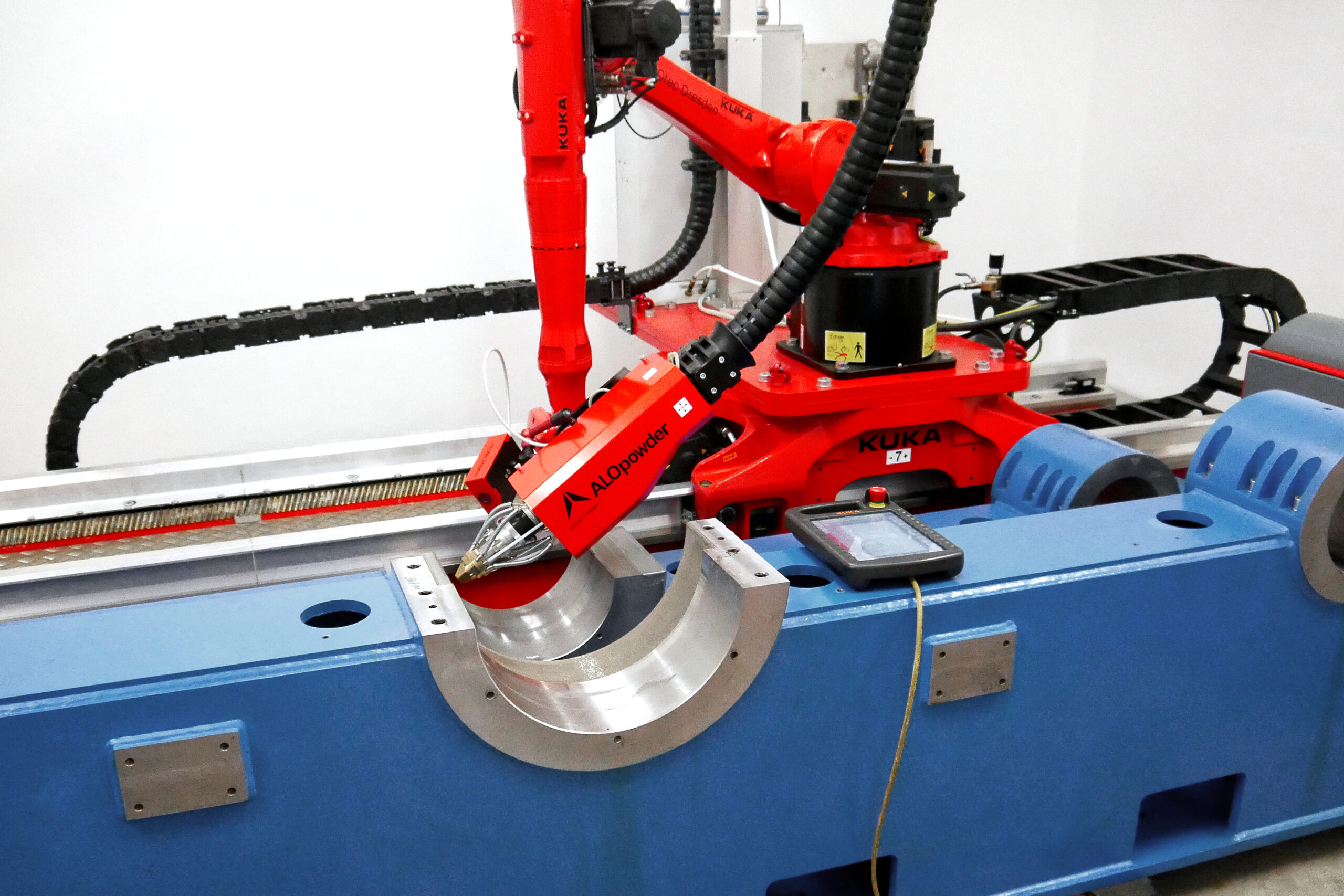

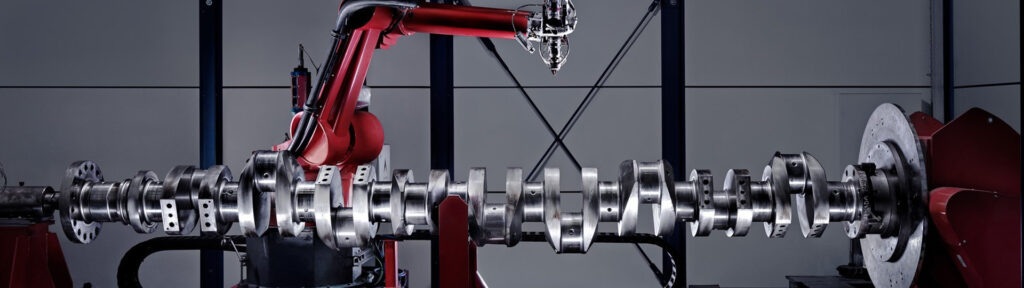

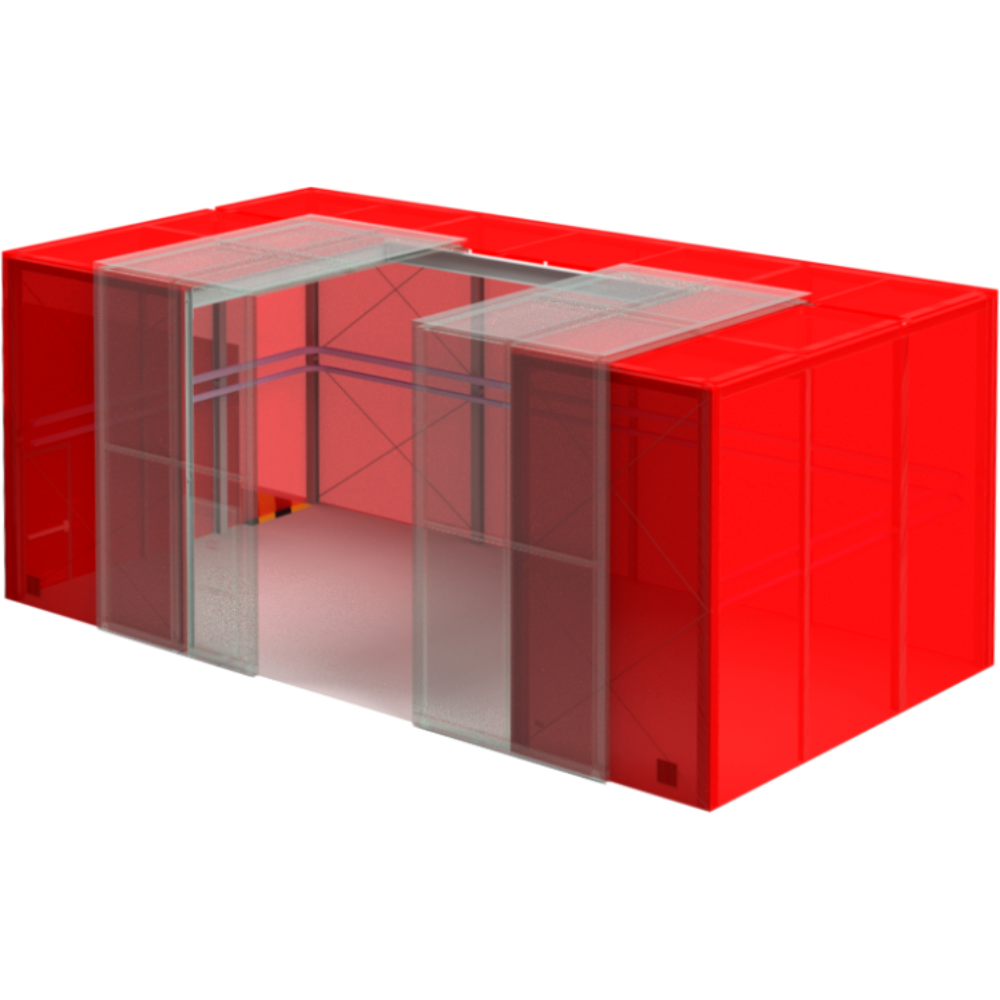

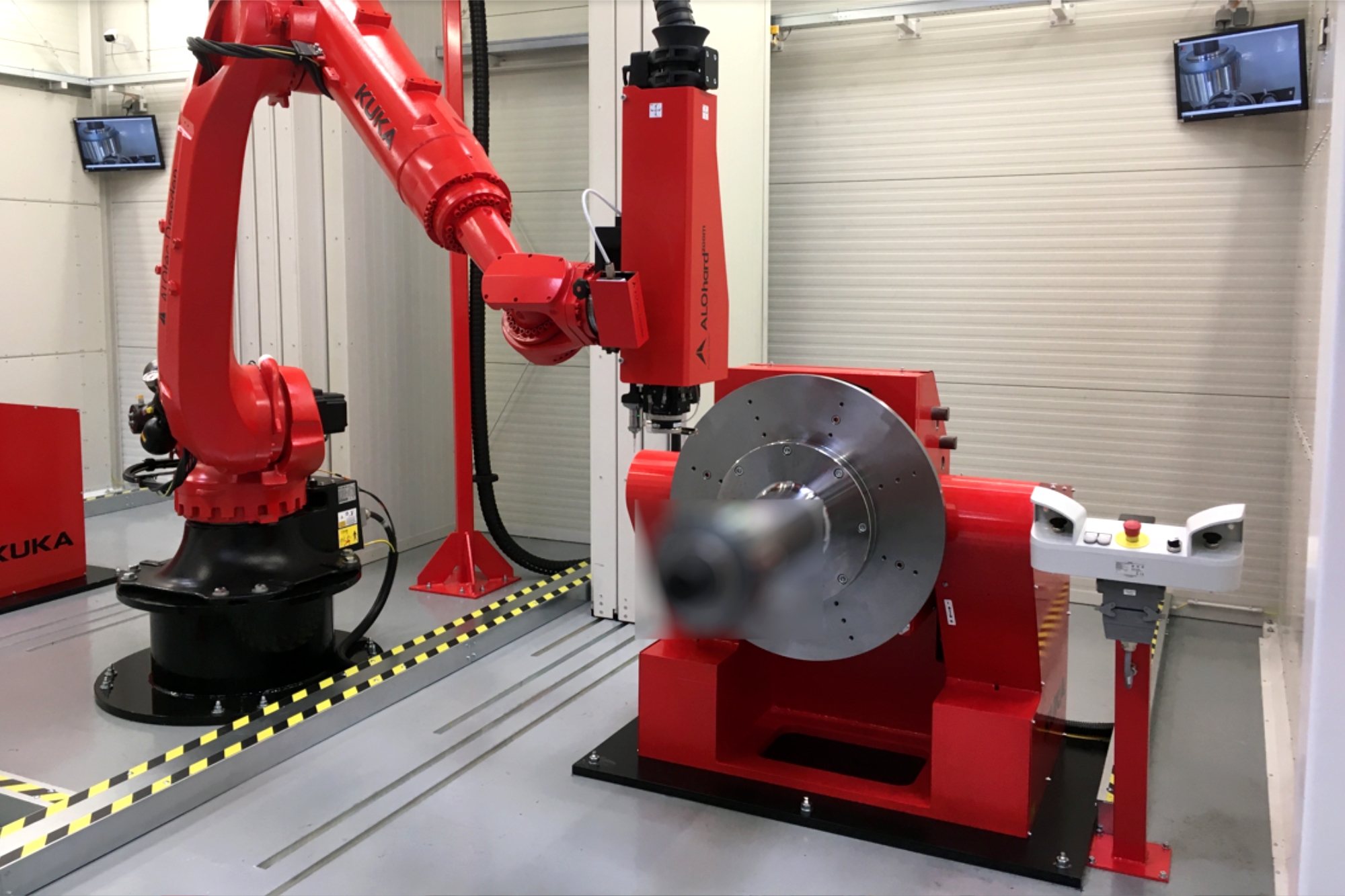

Robot system for laser hardening with turn/tilt table and turn table.

Switzerland · Egerkingen

Härterei Gerster AG

Stationary · Mobile · Hybrid

System engineering

Customised according to your requirements

Laser system engineering

We supply customised robot-based laser systems for laser hardening, laser cladding with powder and wire as well as arc welding for use in tool, mould and mechanical engineering. Our systems are customised and scalable, powerful and flexible.

Depending on the size of your components, we can offer you a stationary, mobile or hybrid system: ALOstation for maximum precision, ALOflex for maximum flexibility and the perfect combination of the two – ALOhybrid.

What you can expect:

Customised systems

and advice

System design

and engineering

100 % tried and

tested technology

Installation and

commissioning

Easy operation thanks

to the use of macros

Training, service

and support

It could hardly be more individual

Stationary, mobile or both

Stationary laser systems

ALOstation

Our ALOstation stationary laser system is customised and designed to meet the requirements and needs of our customers.

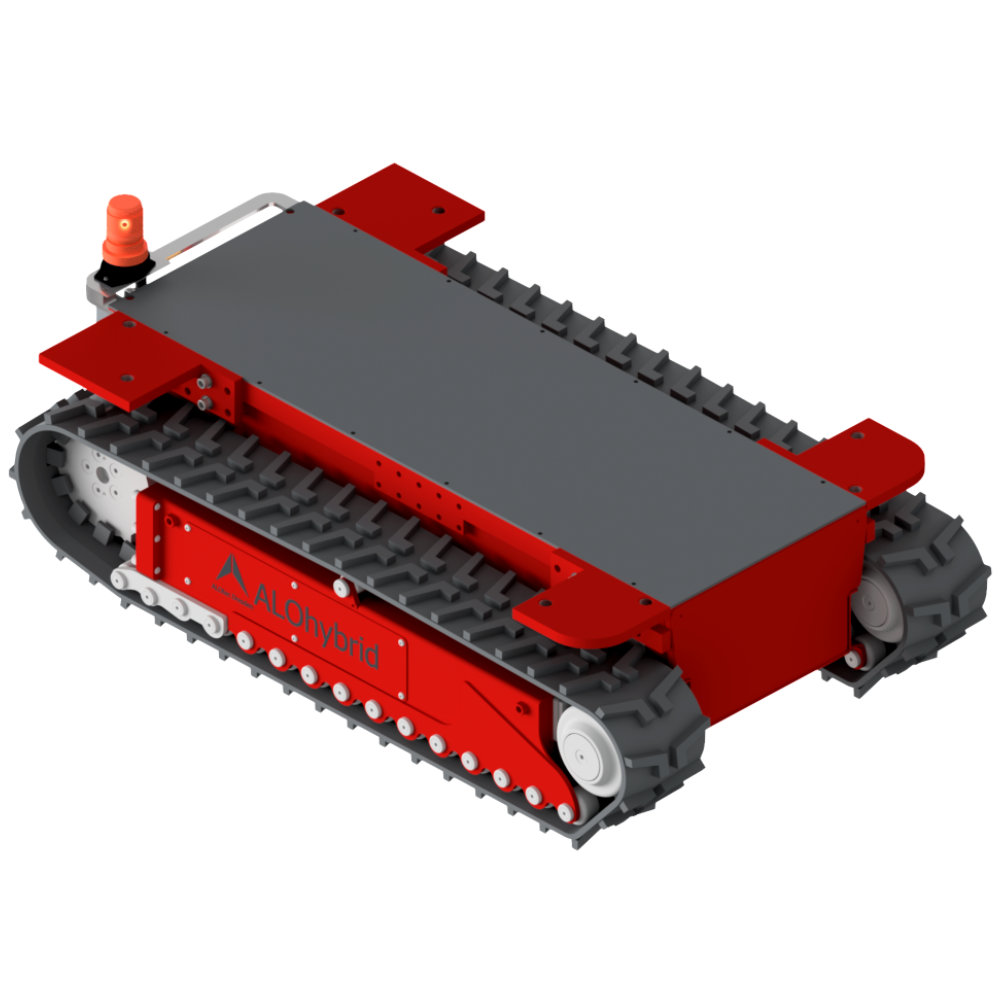

Mobile laser systems

ALOflex

Our flexible ALOflex robot system for mobile laser hardening, cladding and CMT welding. Lightweight and agile like no other mobile laser system.

Customised equipment

System modules

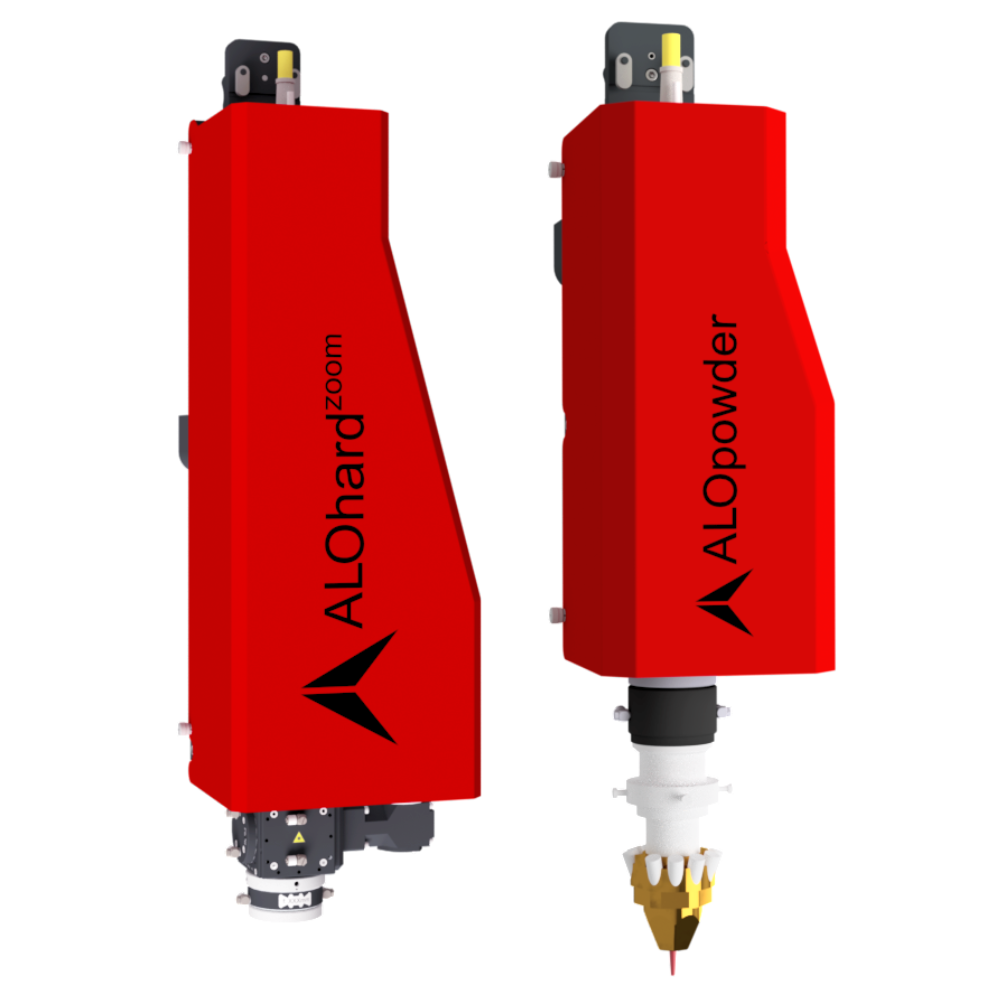

Processing optics

for laser hardening and cladding

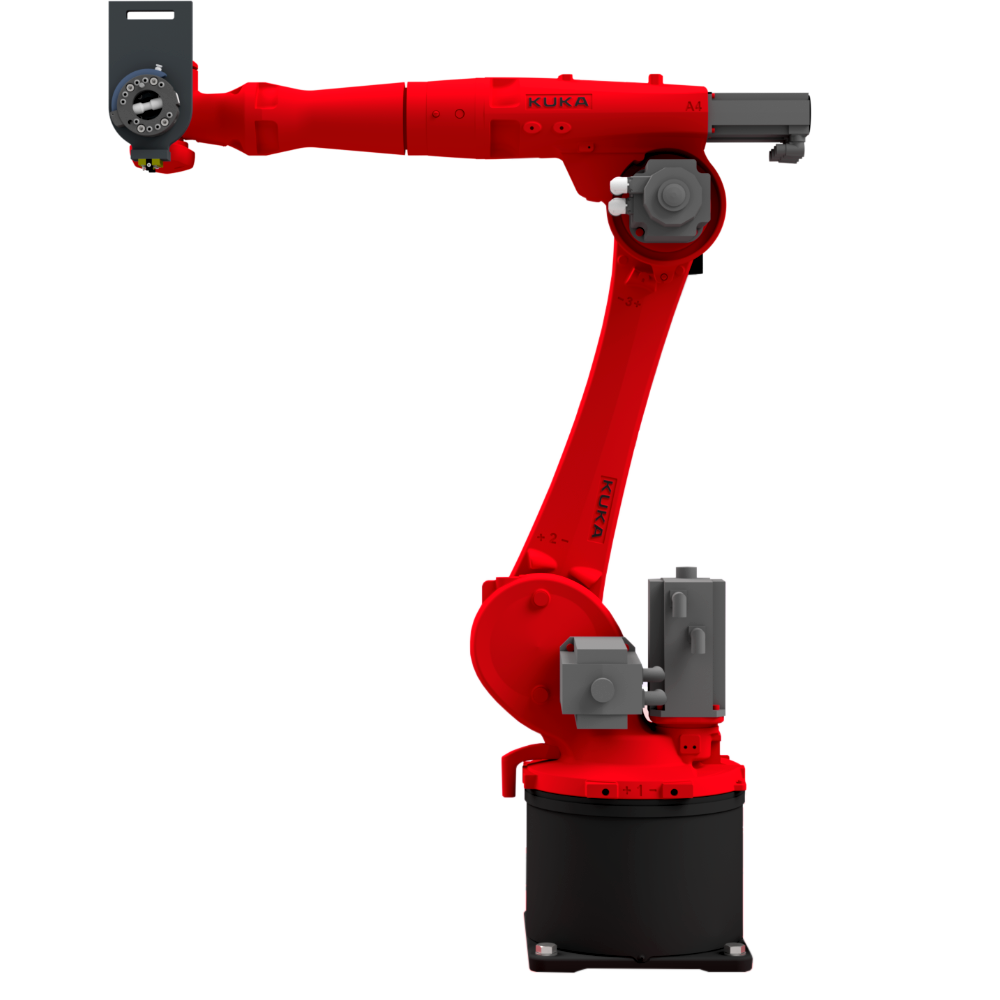

6-axis robot

for 3D laser beam movement

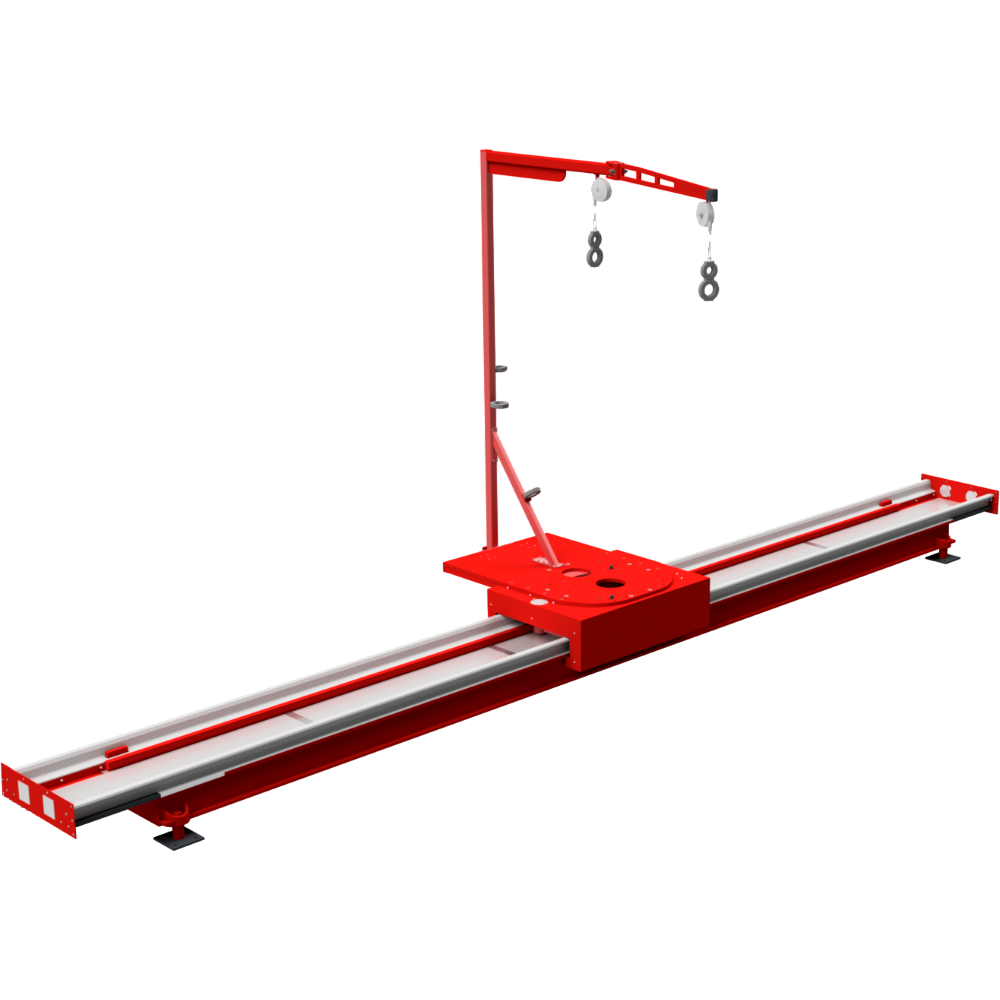

Linear drive unit

with a length of up to 10 metres

e-chassis

with remote control for mobile systems

Turn-tilt table

with 1 or 2 axes for part positioning

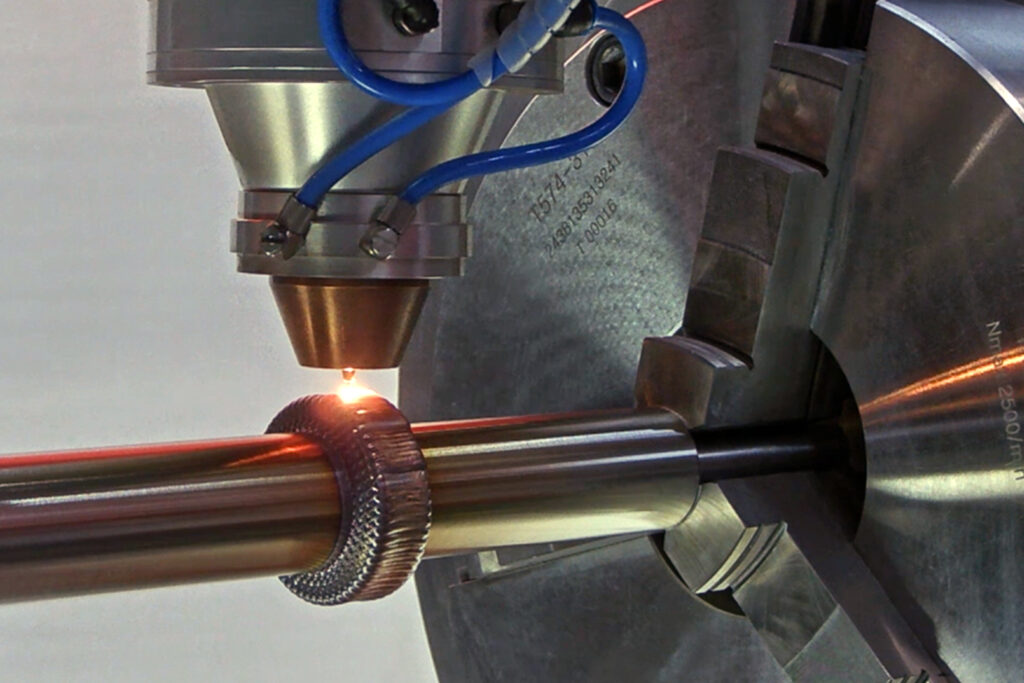

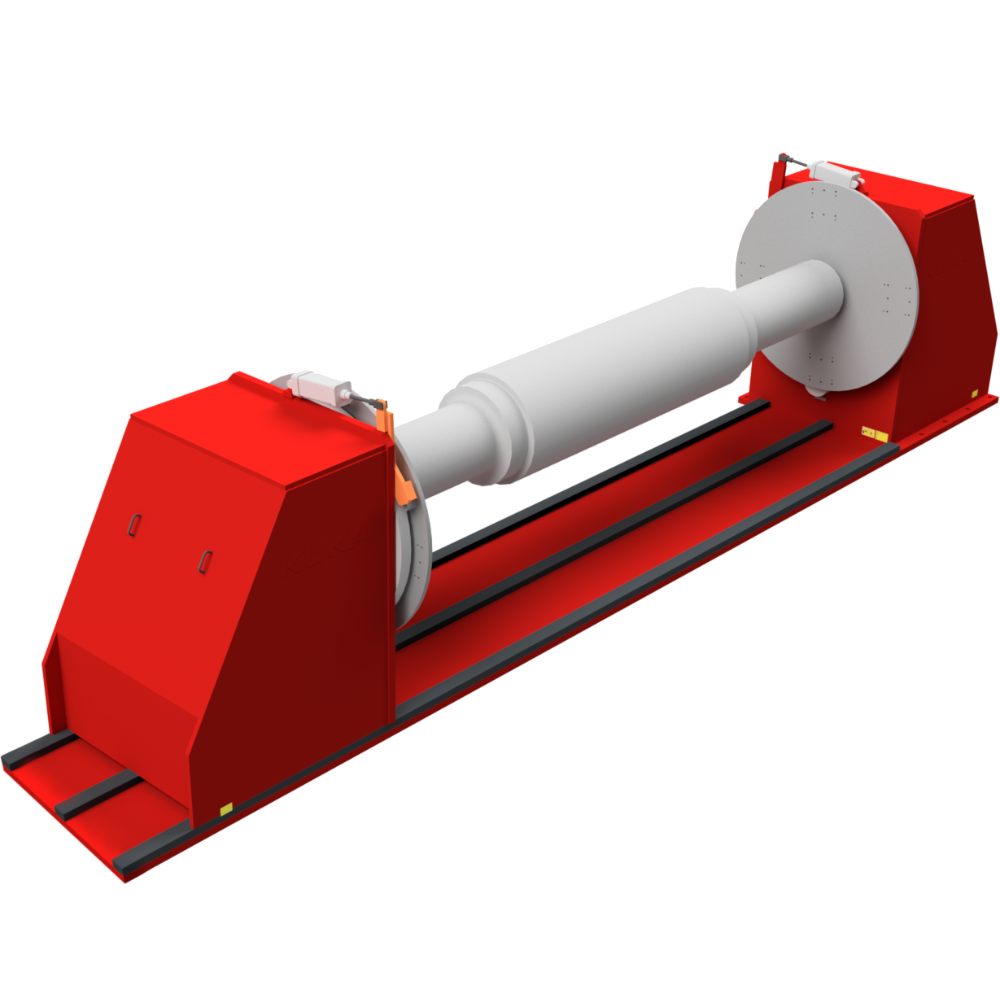

Rotary module

with variable steady rest

Media stations

for stationary or mobile systems

Laser protection as cabin or mobile laser safety barriers

3 ways for quick and safe operation

Easy operation of the systems

The operation of our systems is uncomplicated and easy to learn. In addition, pre-installed assistance programmes (macros) support the system operator in their work. We provide perfect training for system operators – including on-site training at your premises. Our support team is also on hand with help and advice.

Online

Simple path planning through teaching

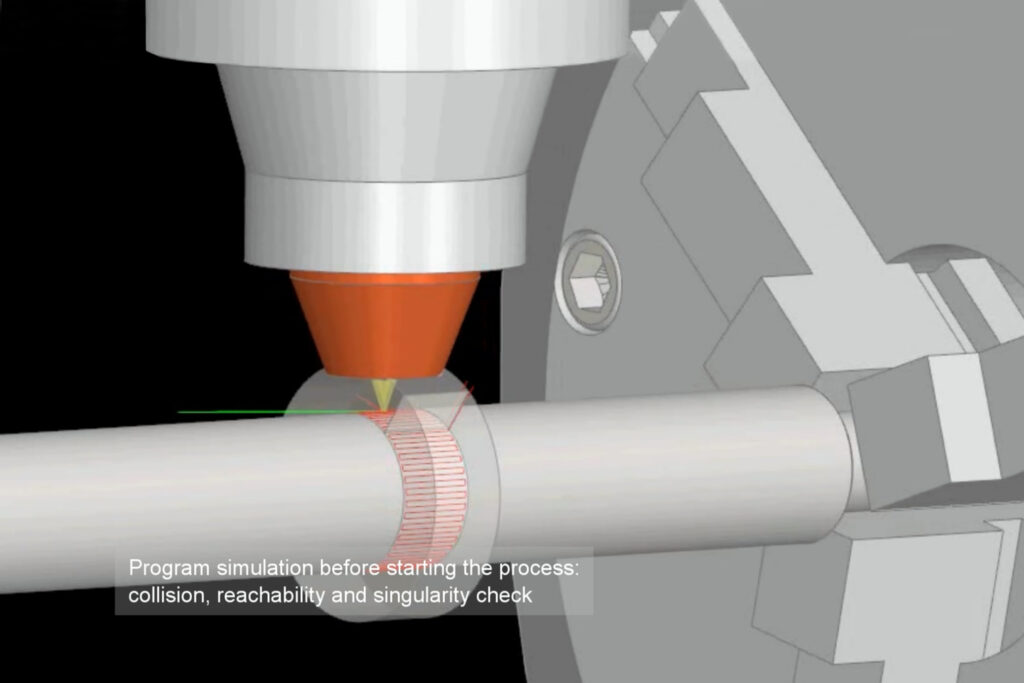

Offline

Creation of paths using CAM software

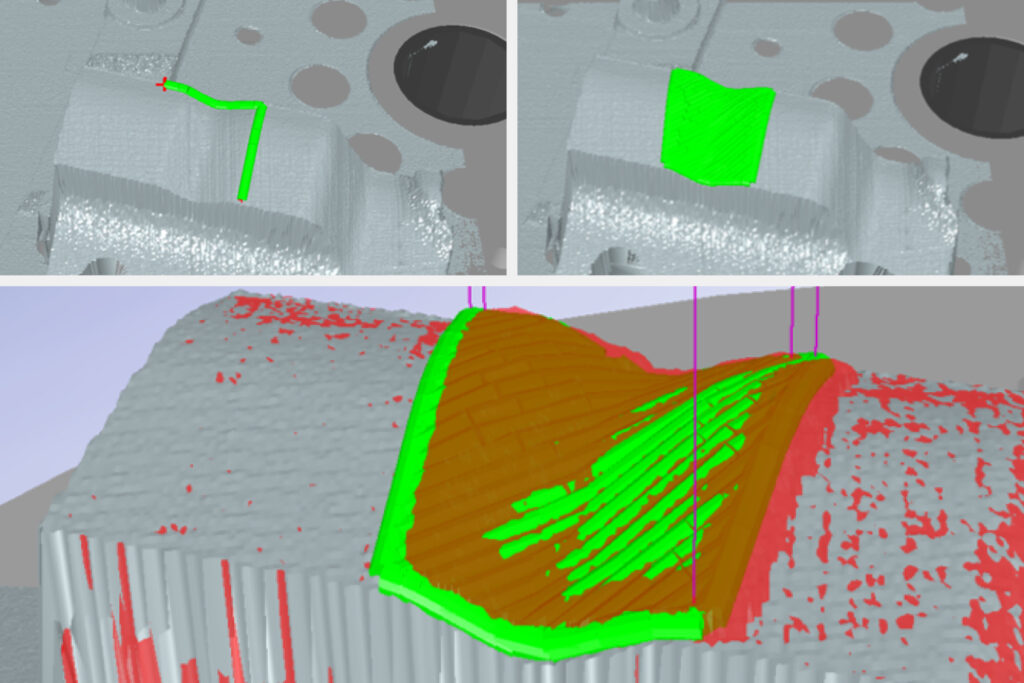

Scanning

Scanning of component surfaces

Macros

Quick and easy system operation thanks to program wizards

4 steps of process control

Quality and occupational safety

Complete system monitoring

Continuous monitoring of laser and machine safety as well as personal safety.

Complete process monitoring

Monitoring of flow rates and safety glasses as well as monitoring of the melting bath for visual process control.

Real-time process control and regulation

Parameter optimisation and laser power control during the process for quality assurance.

Standardised documentation

Continuous documentation of process parameters using OPC UA for standardised data exchange.

The right support at the right time

ALOservice for you

We offer you a service chain to provide you with optimum support in all situations relating to your laser system and production.

Training

on your system

Maintenance

Remote and on-site

Inspection

Remote and on-site

Repair

Remote and on-site

Production

Increasing system capacity and ensuring production capability

System engineering

Around the world

-

System for laser hardening

-

System for laser hardening

Setting up the laser system for hardening.

Switzerland · Egerkingen

Härterei Gerster AG -

System for laser hardening

Construction of the robot system for laser hardening.

Switzerland · Egerkingen

Härterei Gerster AG -

System for laser hardening

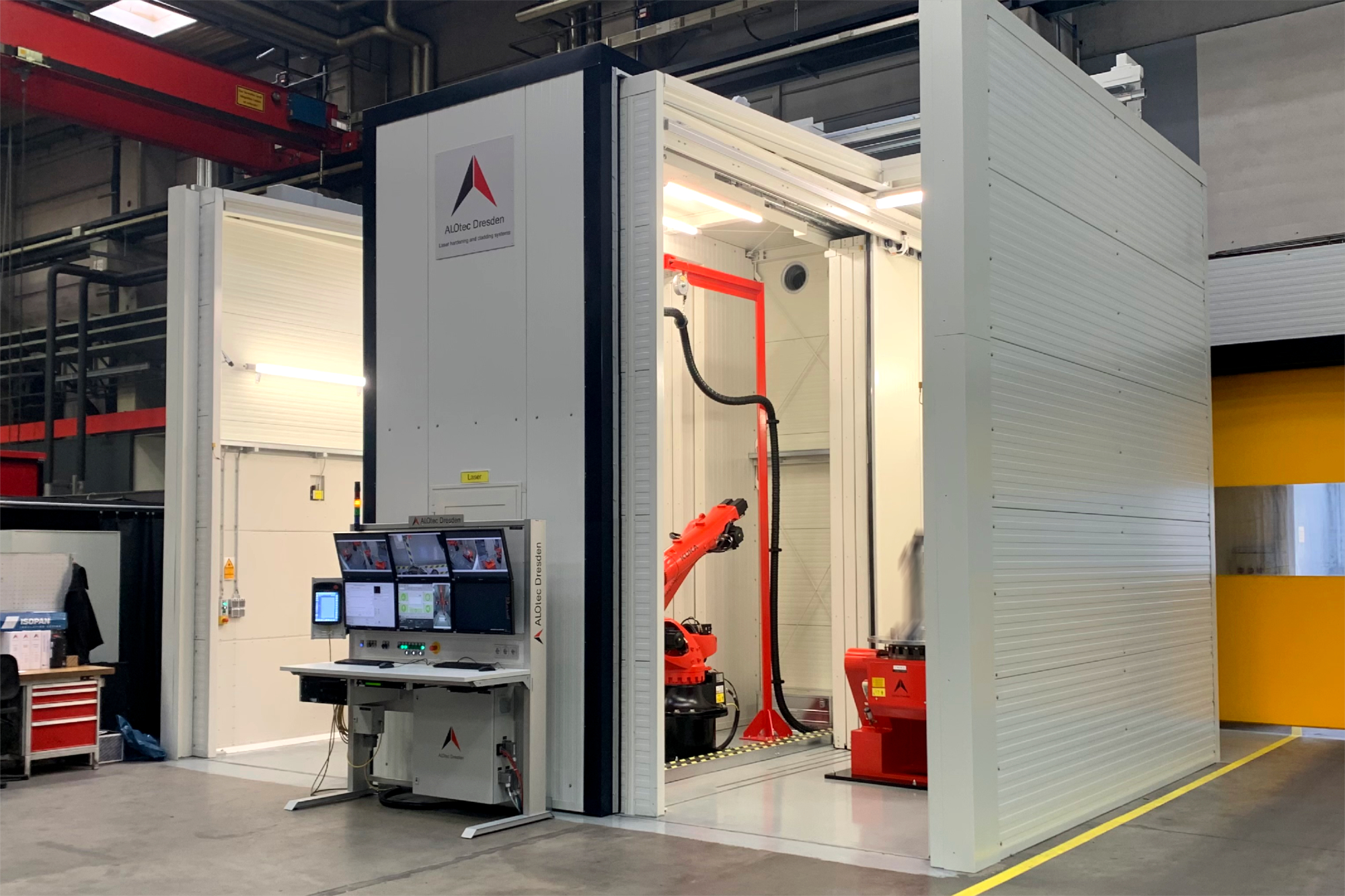

Handover of the robot system for laser hardening to Härterei Gerster AG in Egerkingen, Switzerland.

Switzerland · Egerkingen

Härterei Gerster AG -

System for laser hardening

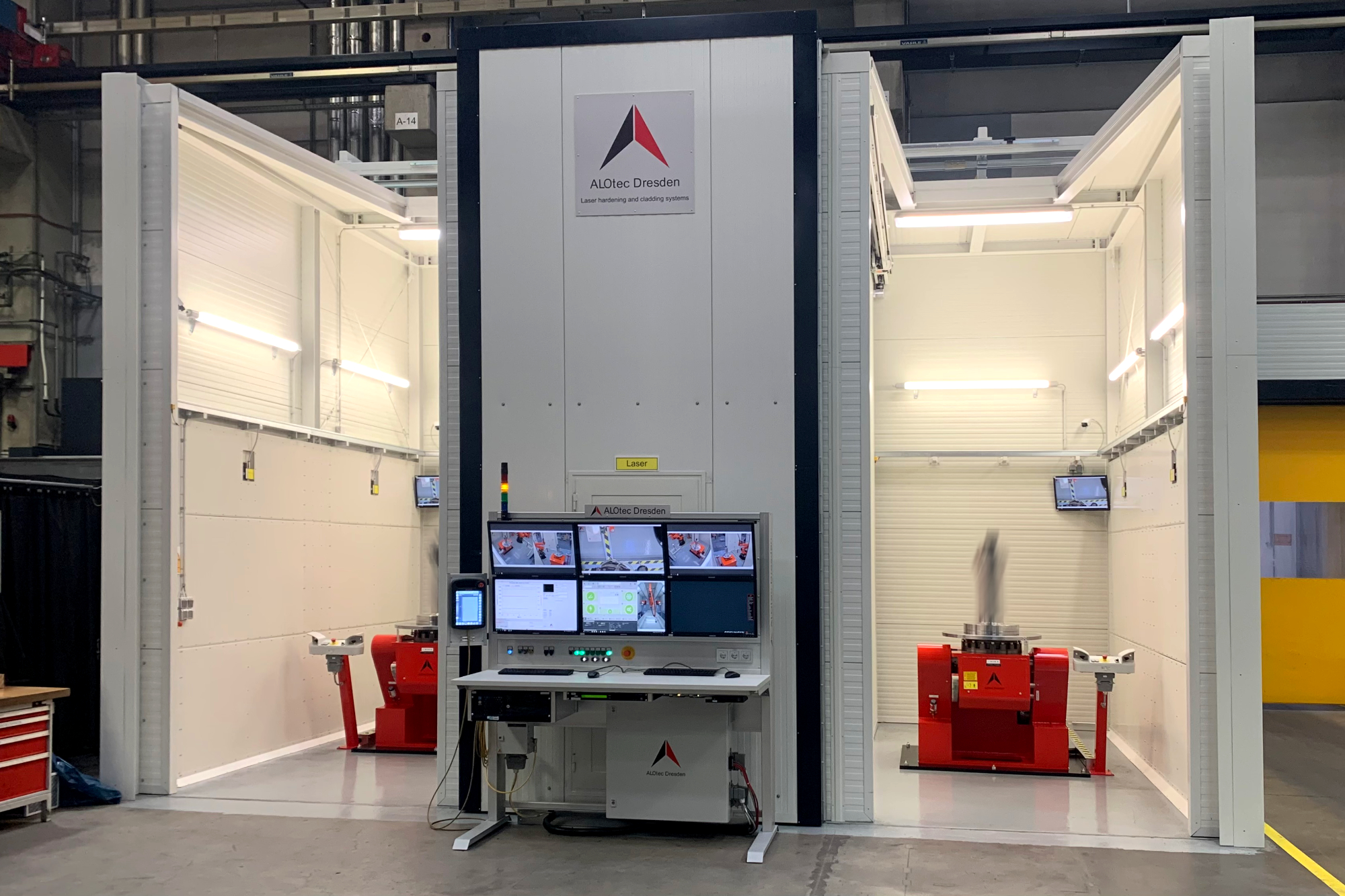

Laser system for hardening with 2 turn-tilt axes in separate laser chambers for increased efficiency and profitability.

Austria

-

System for laser hardening

Laser system for laser hardening with 2 turn-tilt axes in separate laser chambers for increased efficiency and profitability.

Austria

-

System for laser hardening

Robot system for laser hardening with 2 turn-tilt axes in separate laser chambers for increased efficiency and profitability.

Austria

-

System for laser cladding

System for laser powder cladding for external and internal coating including turn/tilt table with 2 axes for part positioning.

Belgium · Waregem

Gearcraft Vanhoutte -

Robot system for laser cladding

Robot system for laser cladding with powder for external and internal coating including turn/tilt table with 2 axes for part positioning.

Belgium · Waregem

Gearcraft Vanhoutte

Looking for a customised system with user-friendly operation?

Let’s talk.

Whether stationary or mobile – our laser systems are easy to operate and pre-installed programme sequences guide you quickly and safely through the processes.

Our systems in the moving picture