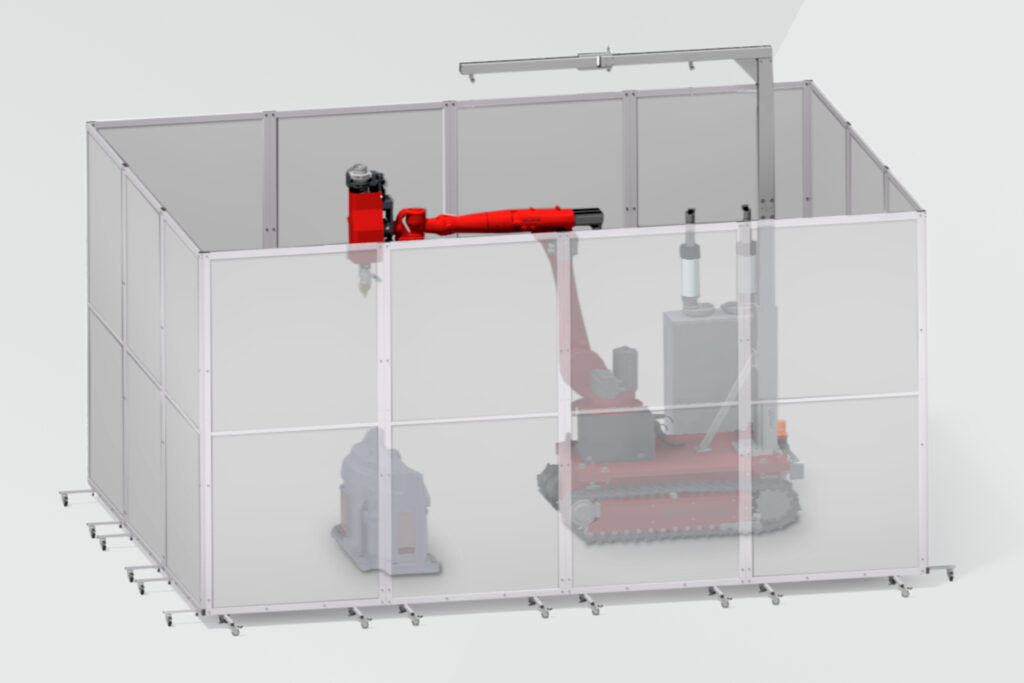

Pull the laser safety barriers out of the mobile station.

Mobile laser safety barriers

ALOprotect

With ALOprotect5 you work more safely.

Laser safety barriers from ALOtec

The laser safety barriers are versatile, intuitive, and quick to set up, and they can be safely and compactly stored through the mobile station. The mobile station is optimized for transport by road, rail, and air freight in terms of dimensions and structure.

The time required for setting up the certified laser safety barriers and installing the associated technical accessories such as door monitoring, emergency stop switches, and laser warning lights is very minimal, taking less than 1 hour.

Naturally laser-safe

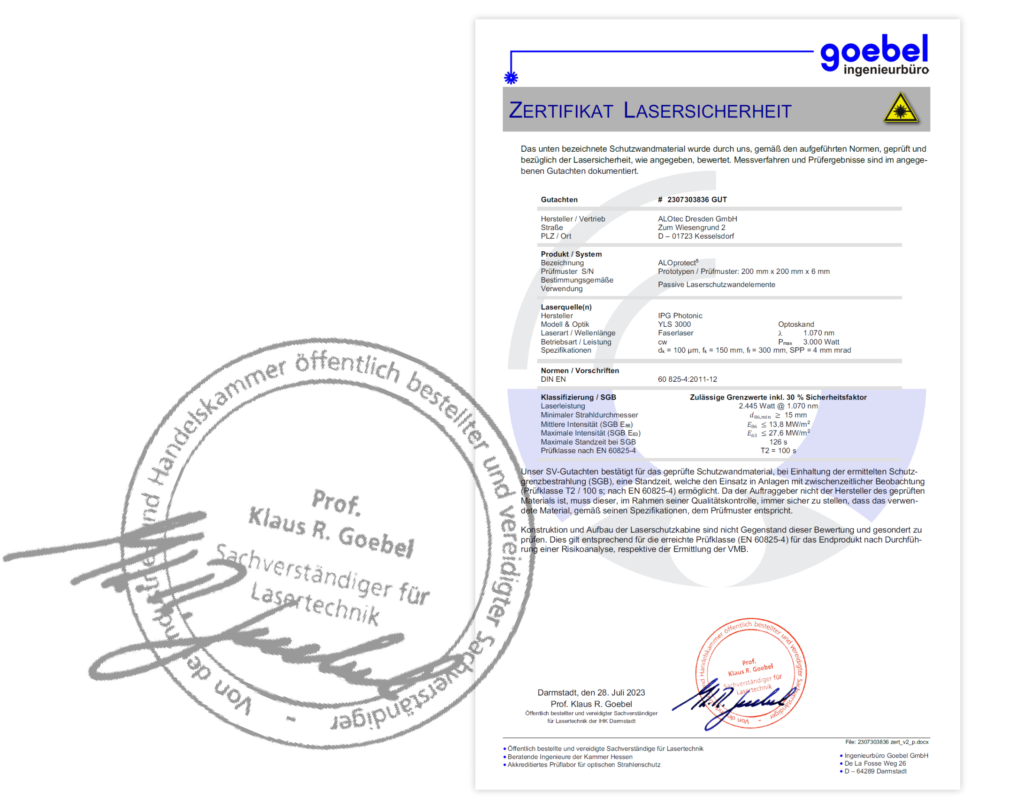

Certification

The ALOprotect5 laser safety walls have been tested and certified by the renowned engineering office of Prof. Klaus R. Göbel.

ALOprotect5 achieves an unprecedented protective exposure limit (E86) of 13.8 MW/m² for a passive, mobile laser safety wall.

With ALOprotect5 you work safer.

Perfectly stored for safe transportation.

Mobile transport stations

The certified laser safety barriers with accessories and the mobile laser system perfectly stored in a mobile station for safe transport.

Transport lugs

For safe loading and unloading and relocation to a second level

14 mobile laser safety barriers

Laser safety compliant with DIN EN 60825-4, size: 1.07 x 2.17 meters

Storage compartments for laser processing heads, tools, and accessories

6 x dustproof boxes and 4 x lockable storage compartments for tools

Crawler with robot

Space for the mobile laser system with 2 robust loading ramps

Crawler locking mechanism

A secure locking mechanism for the crawler during transport

Wheels with brakes

For quick relocation and removable during transport

Assembly of the walls

Simply safe

Safety first for you?

Let’s talk.

With ALOprotect5 you work safer. Our laser safety barriers are certified, modular, easy to assemble and simple to store and transport.

Our laser systems in the moving picture