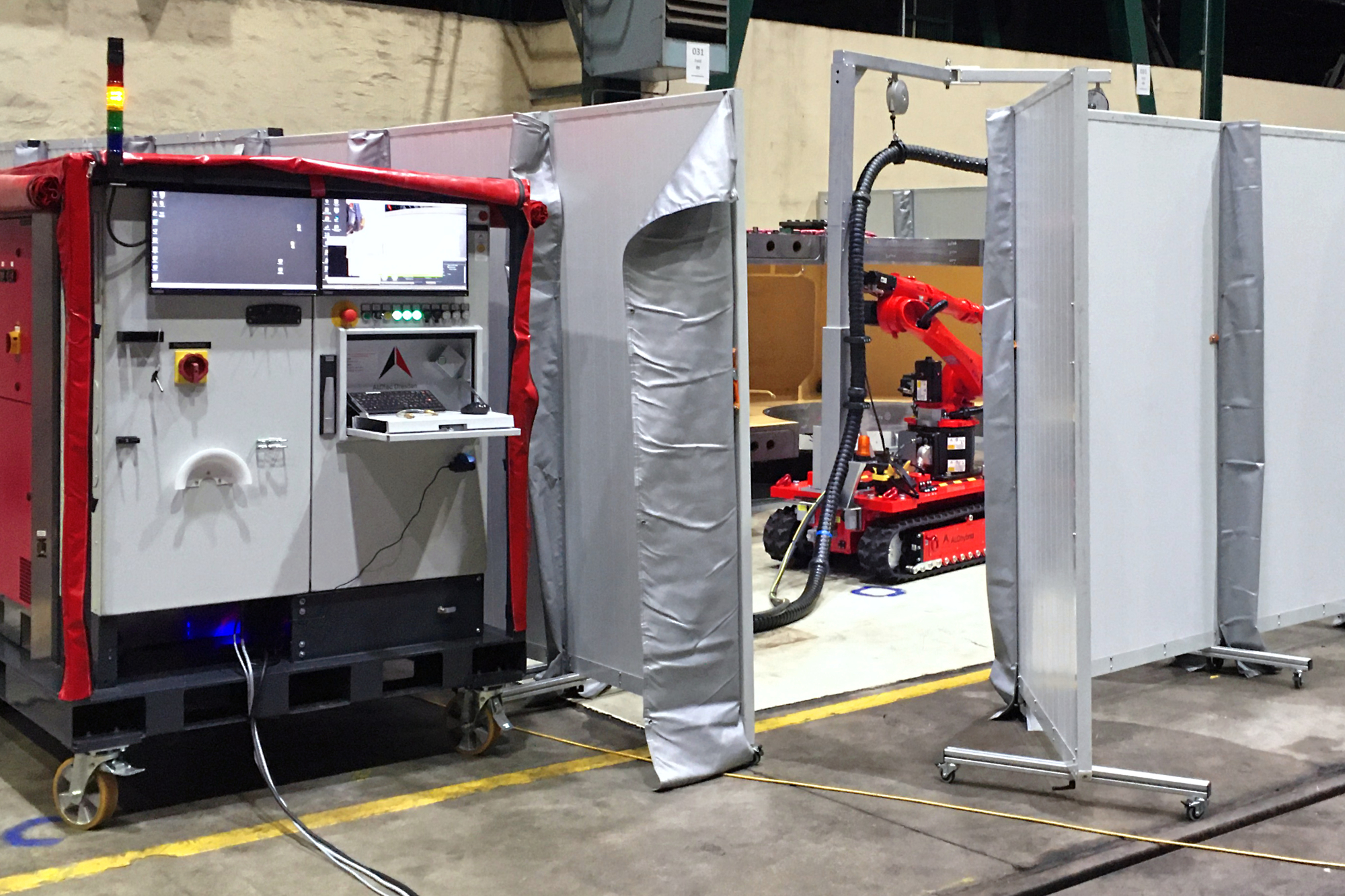

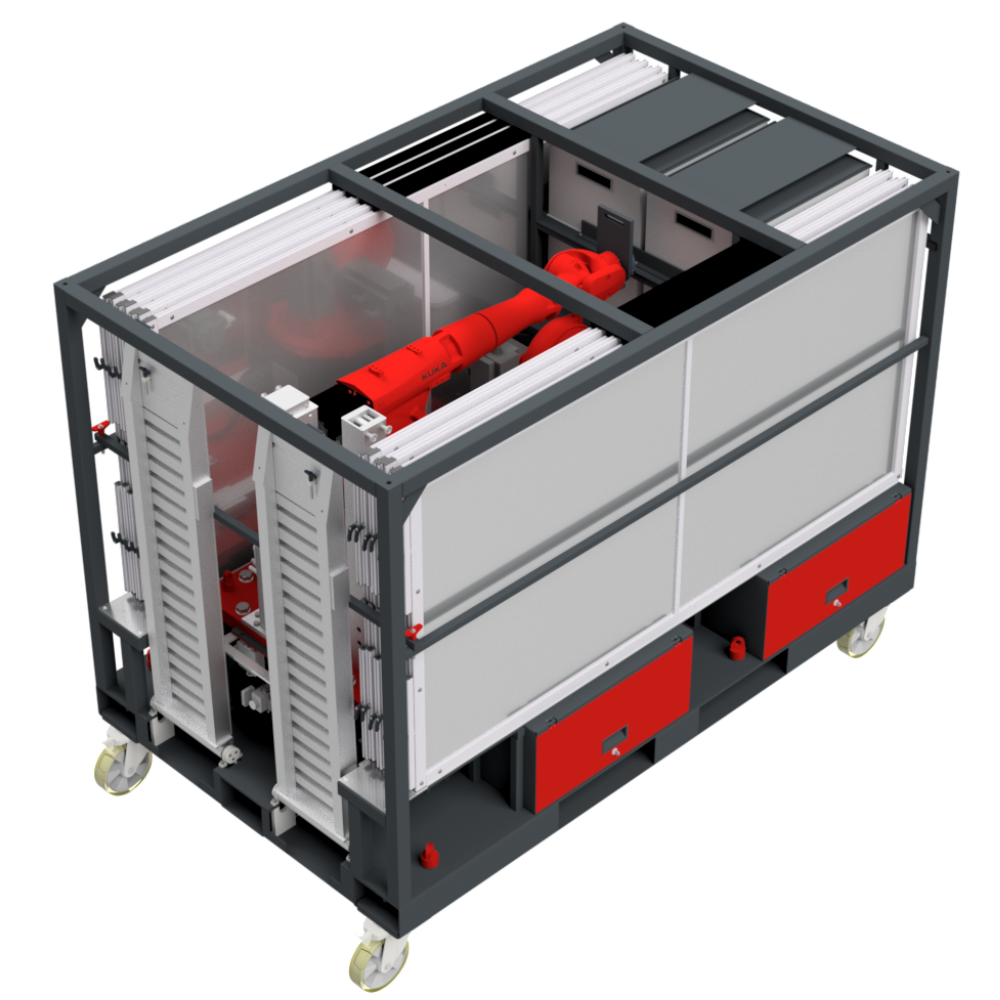

The components of the laser system are compactly stowed away for easy transportation.

Mobile and flexible

ALOflex

ALOflex

Mobile laser systems

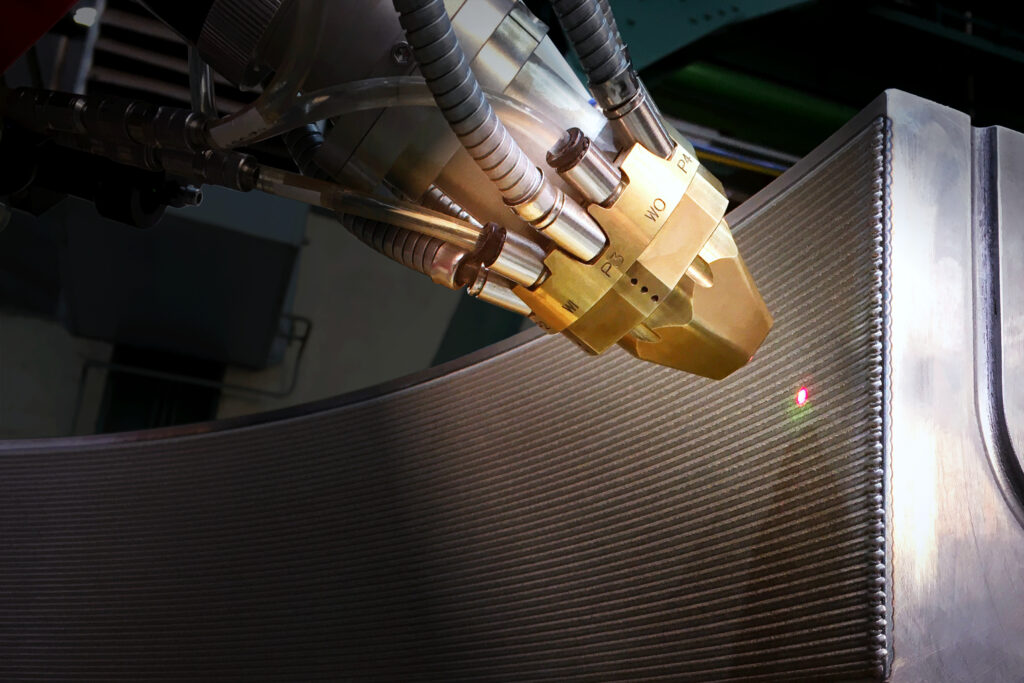

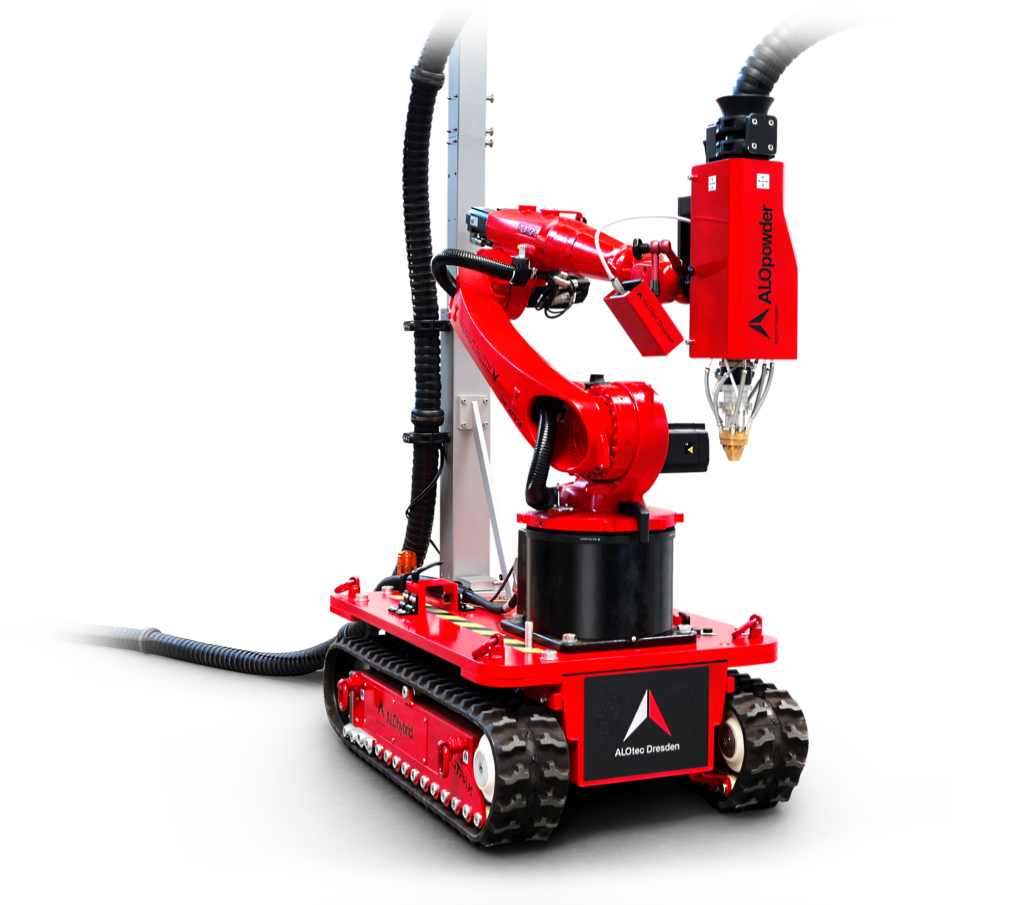

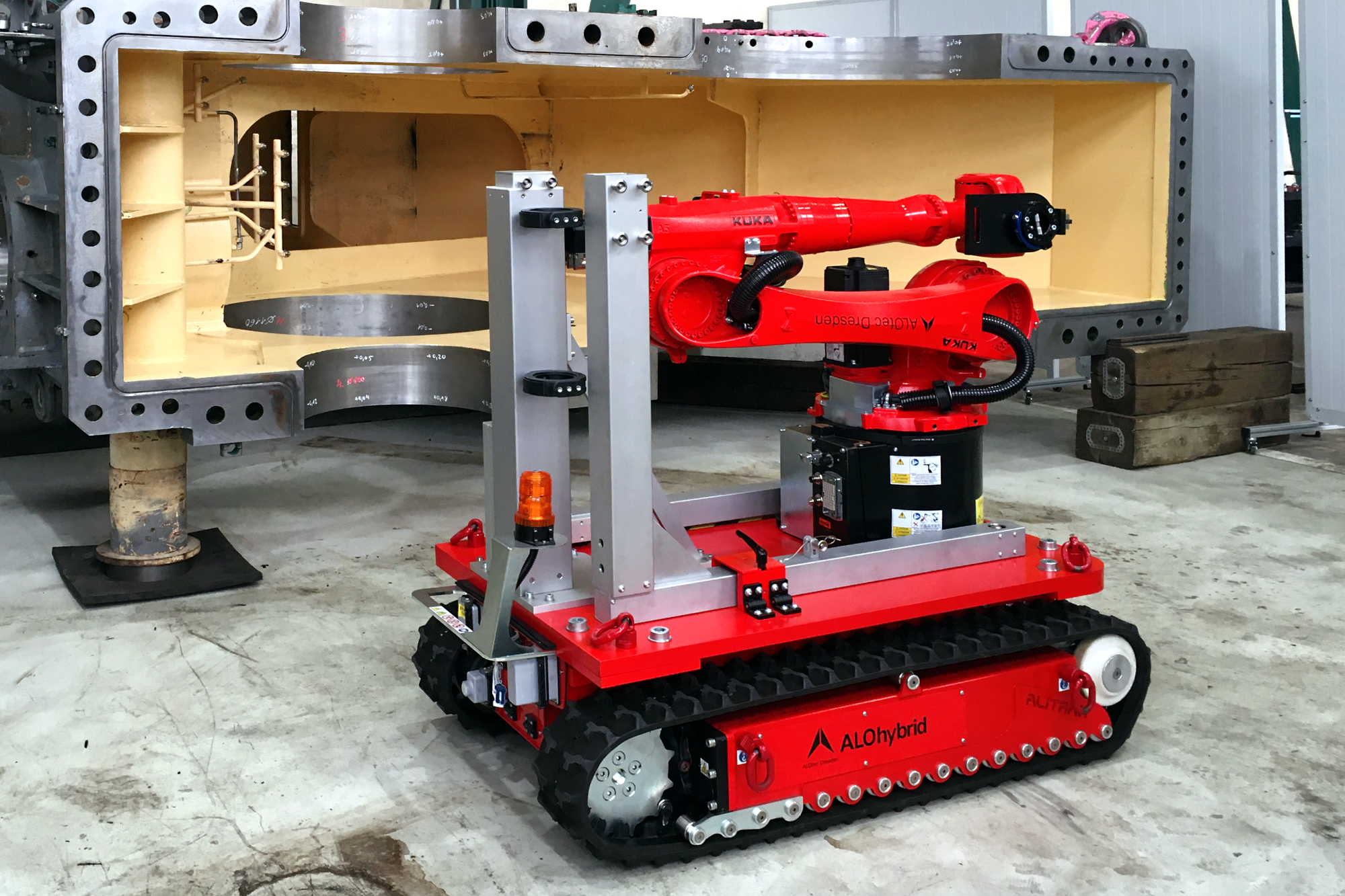

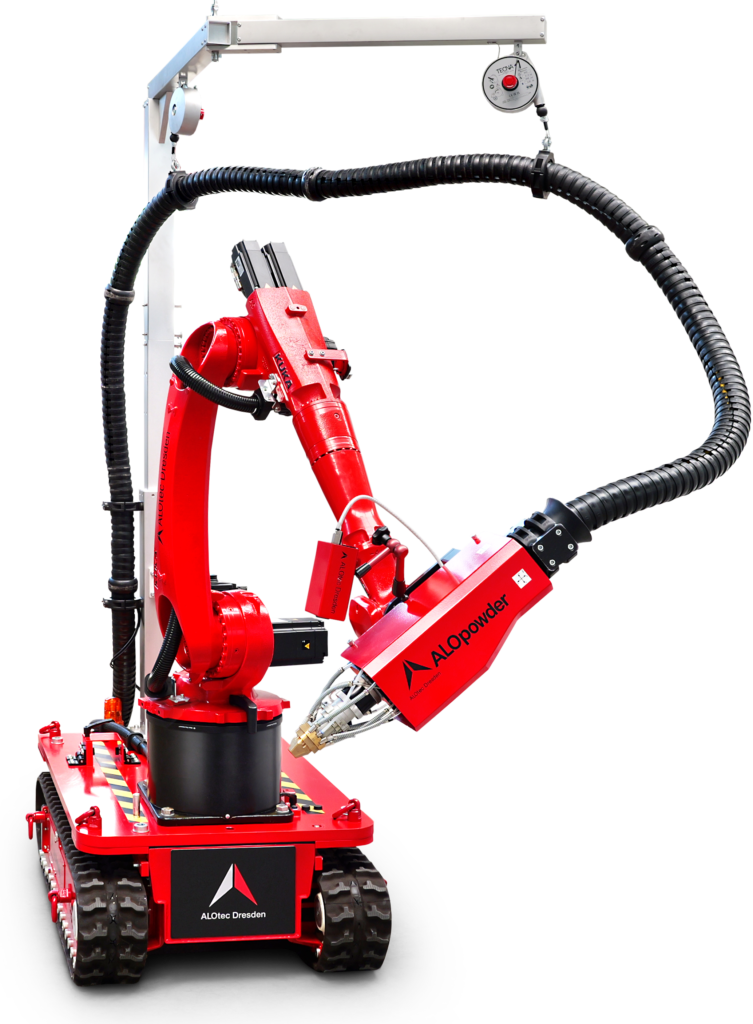

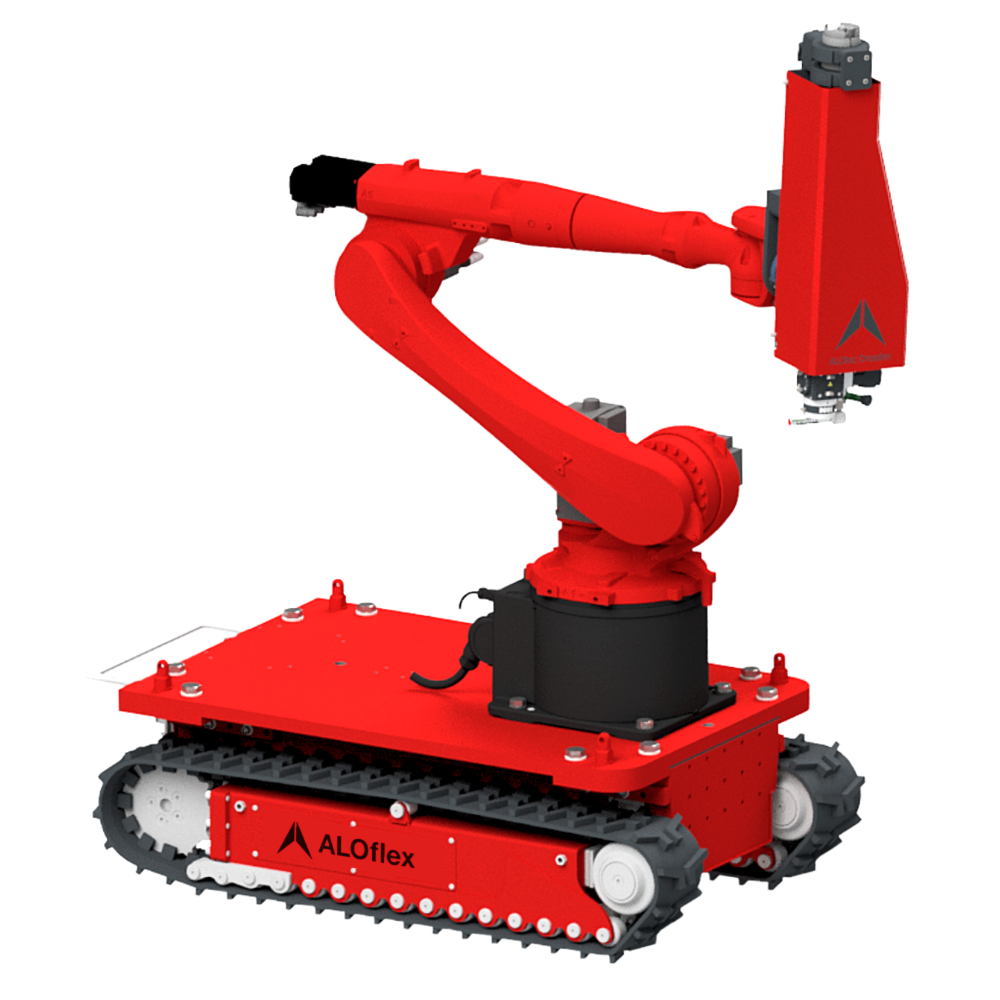

The ALOflex is a flexible robot system for mobile laser hardening, laser cladding and CMT welding.

More flexibility with up to 10 kW laser power for laser hardening with zoom or scan optics, laser cladding with powder or wire for external & internal coating (powder) and CMT welding directly on the component at the customer’s site!

Highest flexibility – smallest dimensions

The ALOflex concept

With the ALOflex mobile laser system, we have deliberately decided to outsource sensitive units to the mobile media station. Dust-sensitive components such as the cooler, PC, laser and monitor are not exposed to direct laser operation and are therefore fully protected. The chassis with robot can be kept as light and compact, agile and flexible as no other mobile laser system.

The robot is connected to the media station via a 15 metre long, flexible energy chain and has a huge, mobile work area.

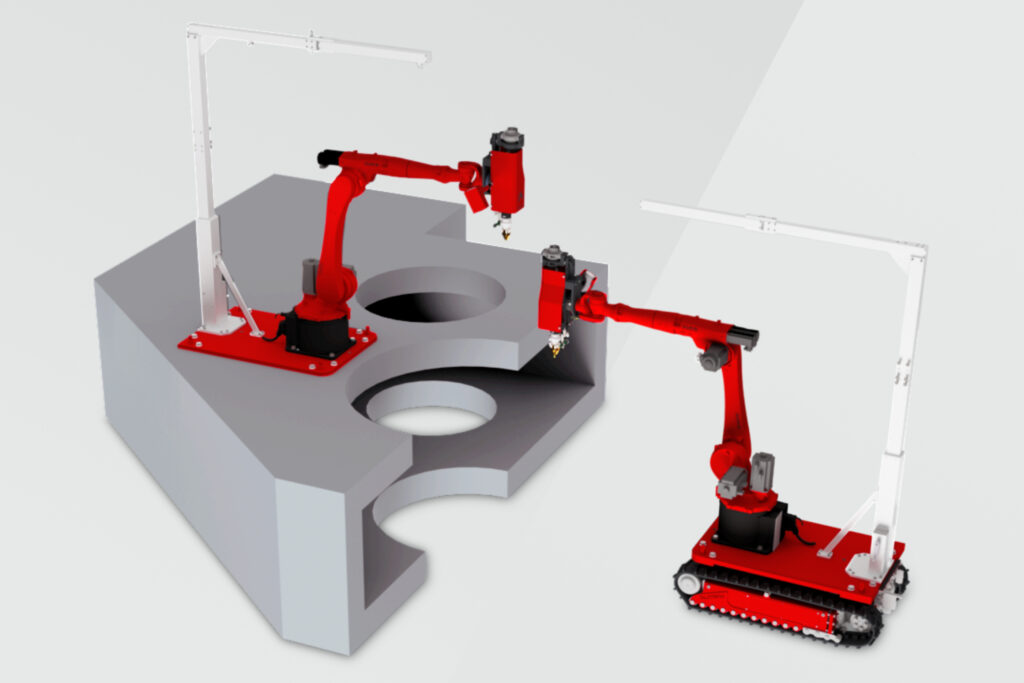

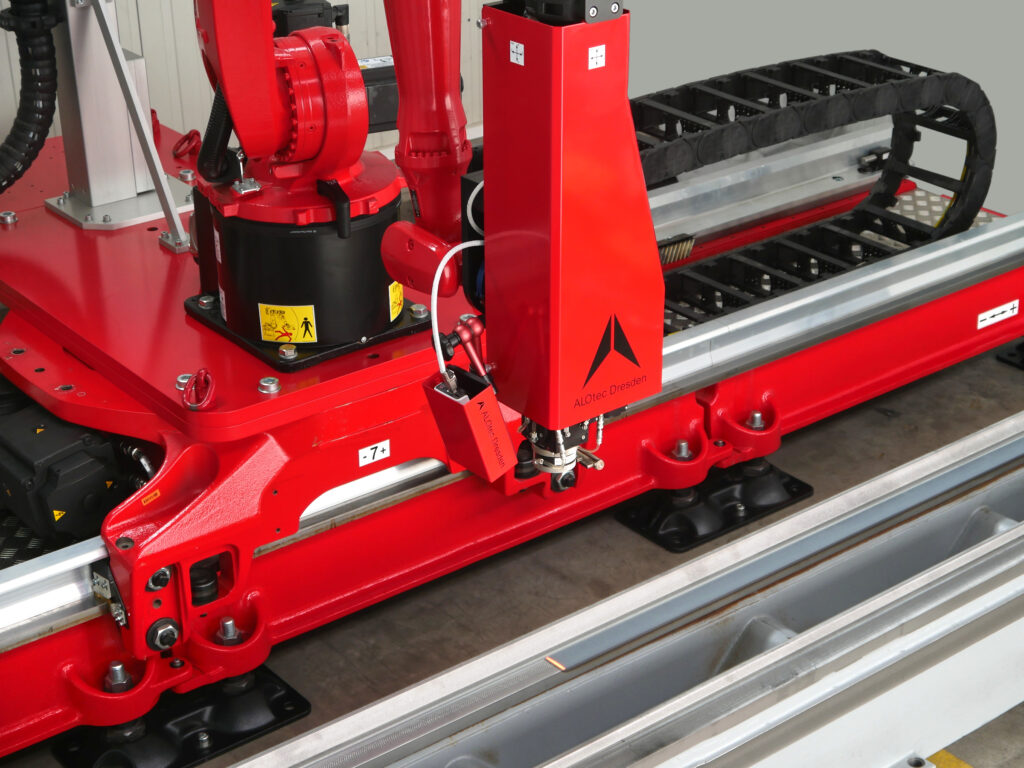

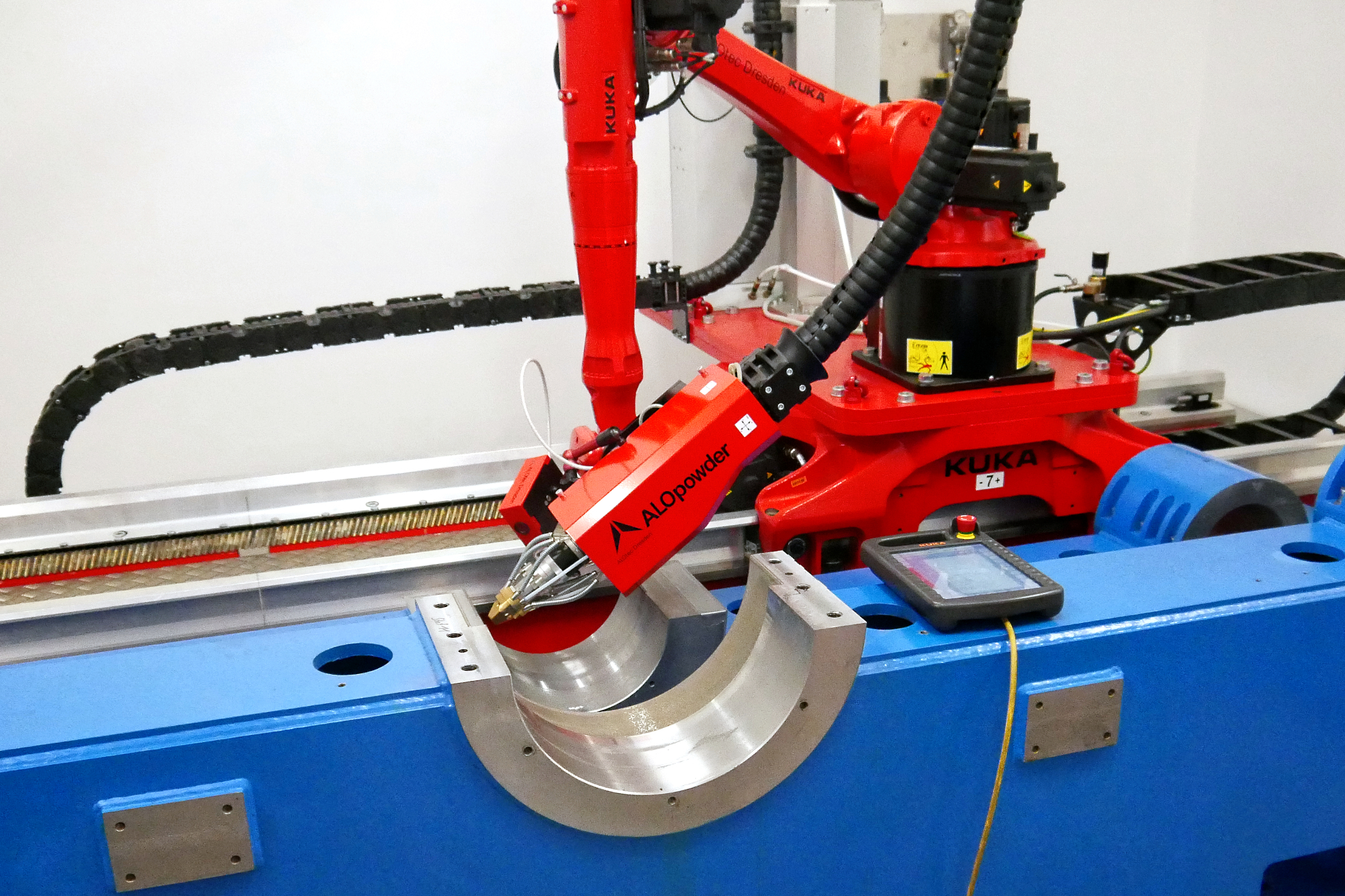

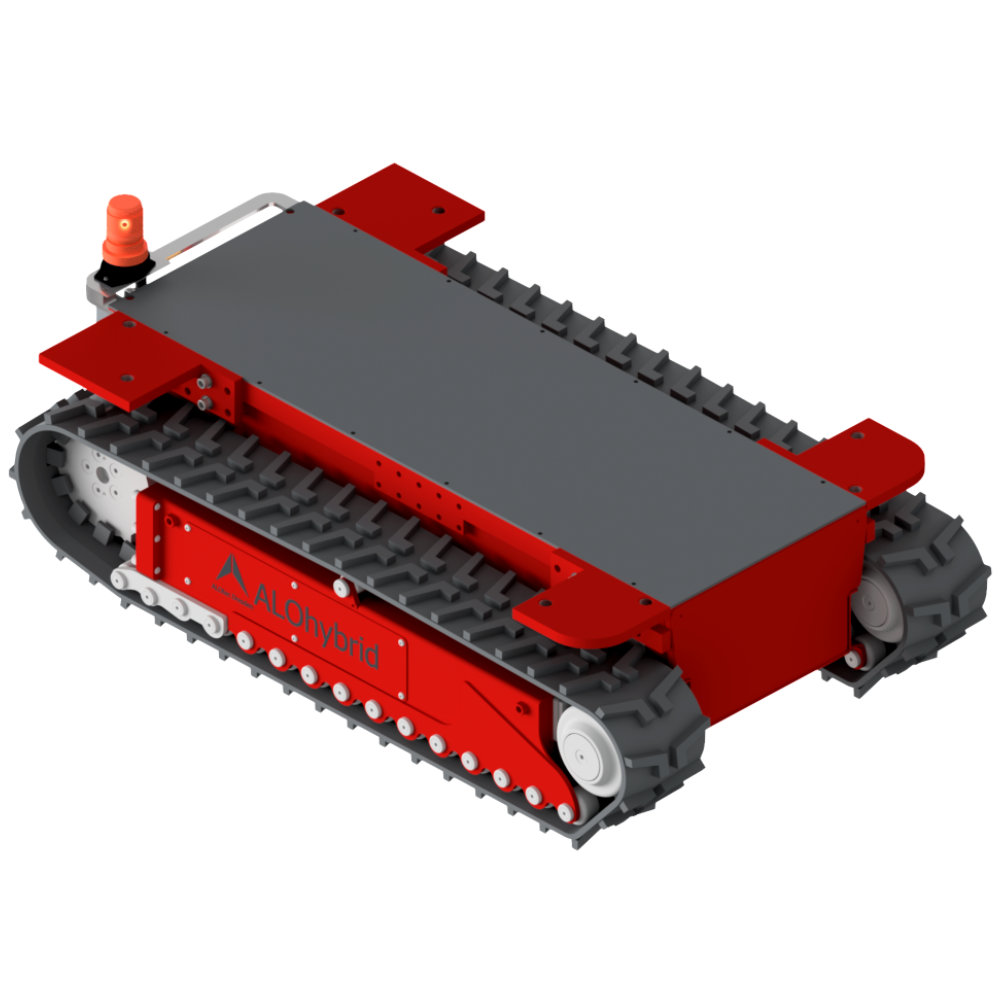

Another advantage of the ALOflex is that the robot can be detached from the crawler track and used directly on a component or on a linear unit as an ALOhybrid with the benefits of a stationary laser processing system.

ALOflex – simply flexible and mobile!

ALOflex mobile laser system

Compact and agile

The ALOflex is the most flexible laser processing system for laser hardening, laser cladding with powder and wire and CMT welding.

Fits on Euro pallets Ideal for confined areas

Use on component High occupational safety

Linear unit can be used 15 m long energy chain

Technology in mobile use

Wide range of applications

![]() ALOhard and ALOhardzoom laser hardening, ALOpowder laser powder cladding and ALOarc CMT welding in mould and tool making and mechanical engineering

ALOhard and ALOhardzoom laser hardening, ALOpowder laser powder cladding and ALOarc CMT welding in mould and tool making and mechanical engineering

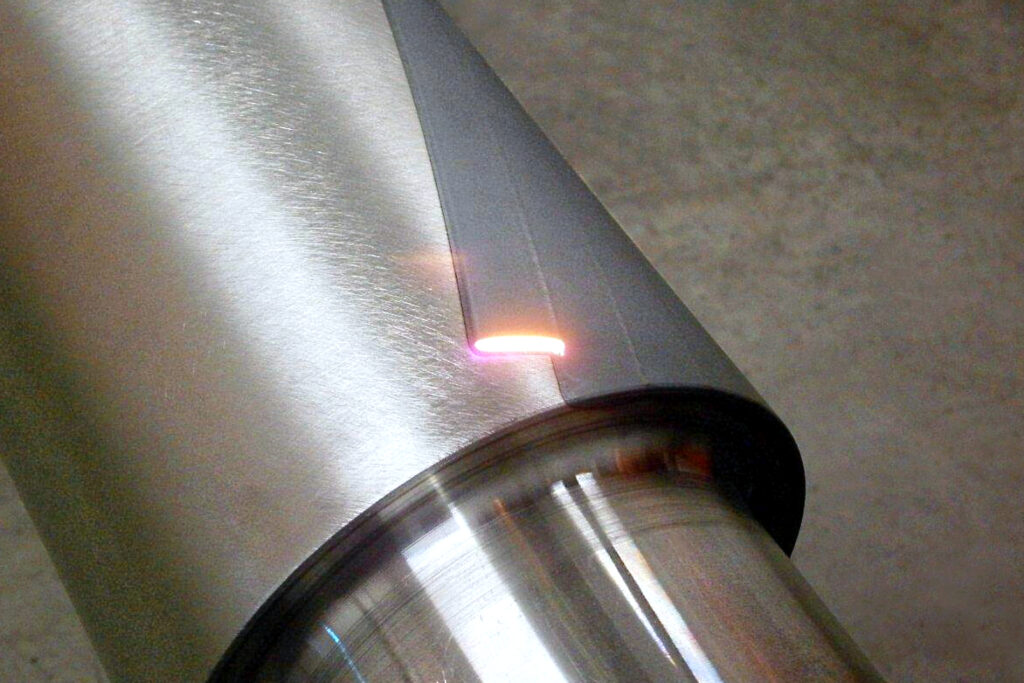

![]() Specific hardening of metallic surfaces and repair or reconditioning of highly stressed component surfaces

Specific hardening of metallic surfaces and repair or reconditioning of highly stressed component surfaces

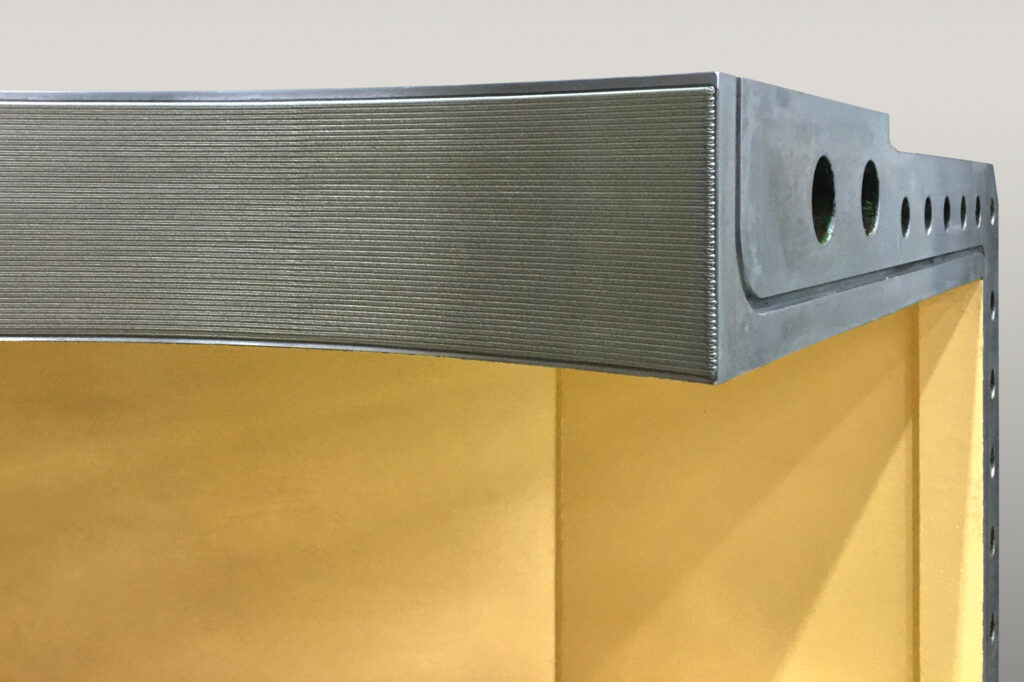

![]() Suitable for processing forming tools, machine parts, cutting tools or screw conveyors, bearing seats, rollers and much more

Suitable for processing forming tools, machine parts, cutting tools or screw conveyors, bearing seats, rollers and much more

![]() Practical example: Mobile laser hardening of 14 meter long and 25 ton pressure sleeves from an open die forge on site at the customer’s premises.

Practical example: Mobile laser hardening of 14 meter long and 25 ton pressure sleeves from an open die forge on site at the customer’s premises.

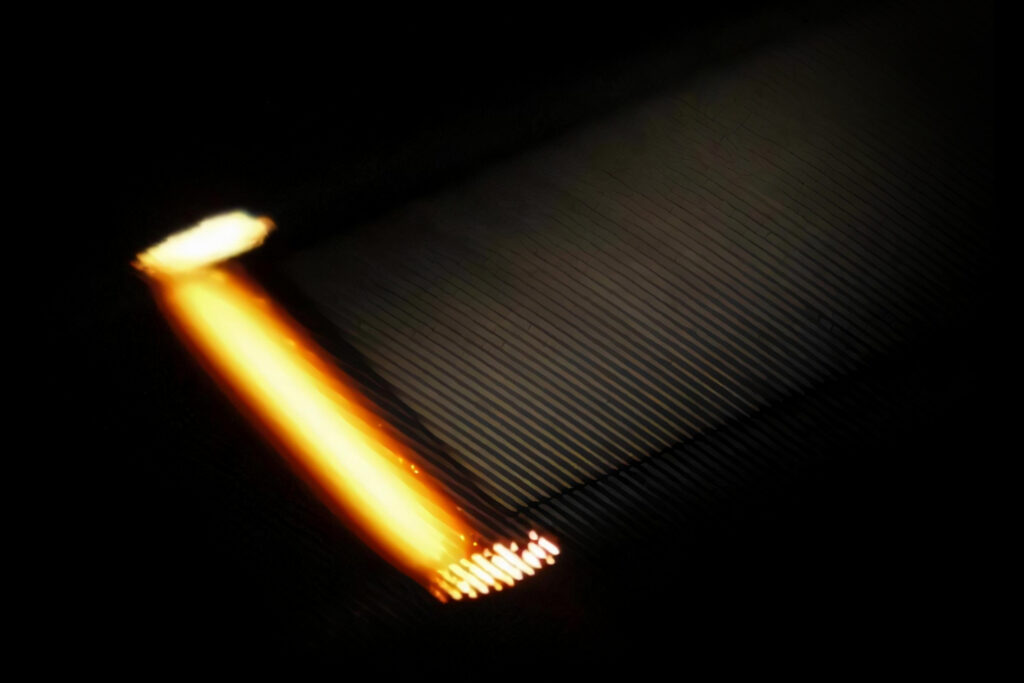

Laser hardening

with fixed and variable laser track widths

Arc welding

CMT welding with ALOarc

Cladding

with powder

Additional applications can be optionally employed: laser powder cladding with interior cladding optics* ALOpowderID, laser wire cladding* ALOwire, hardening with dynamic scanning optics* ALOhardscan, and a hybrid technology combining wire and powder cladding* ALOtwin.

*For these applications, modules of the mobile laser system need to be adjusted.

On site at the customer component

Mobile processing

-

Transporting the mobile laser system

-

Loading the mobile laser system

The components of the laser system are located in transport-optimized stations and are therefore quick to load and easy to transport.

-

Setting up the mobile laser system

The mobile laser system is positioned and set up on site on the component.

-

Teaching the mobile laser system

Simple creation of the welding paths on the component by teaching the mobile laser system.

-

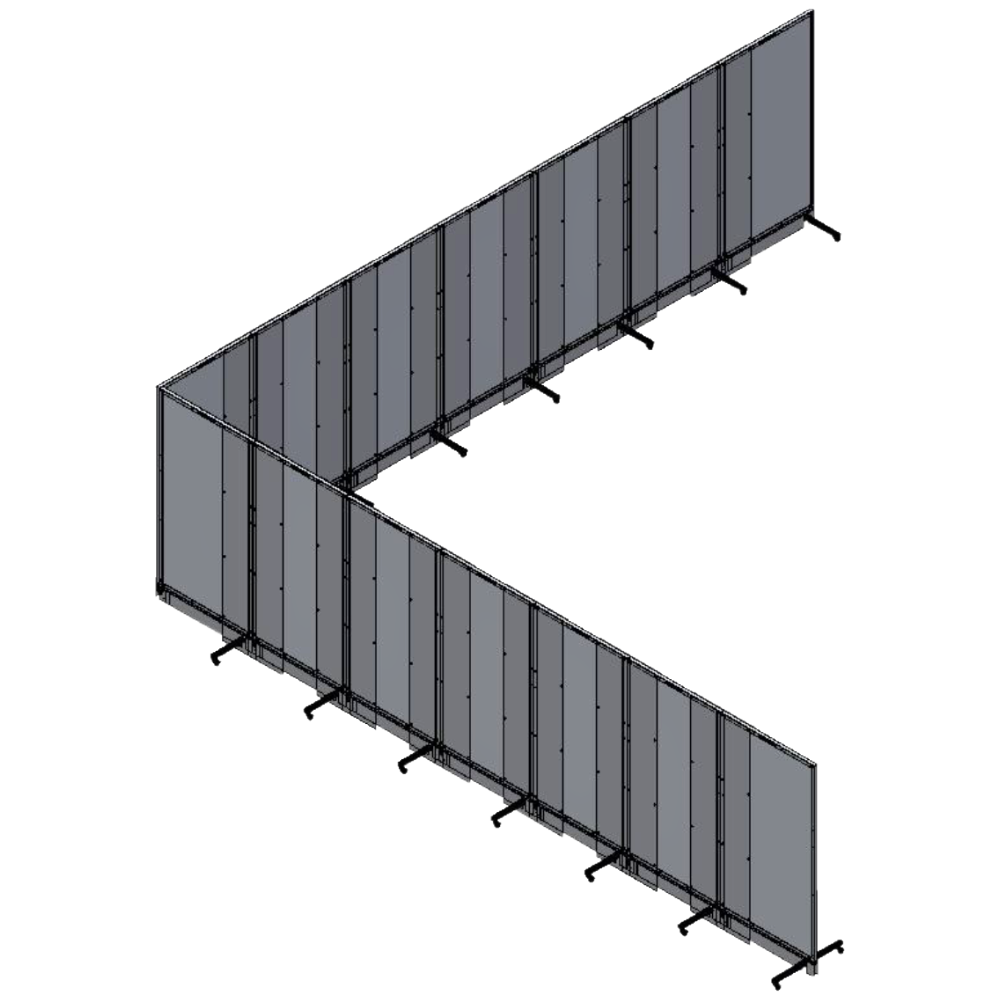

Setting up the laser safety barriers

Setting up the certified laser safety barriers around the component with the mobile laser system.

-

Setting up process control

Setting up system monitoring and process control, laser power measurement and documentation of process parameters using OPC UA.

-

Fully set up mobile laser system

The system and the powder feeder are positioned in front of the component and fully set up.

-

Process recording

Recording of the process camera during laser powder cladding on the component.

-

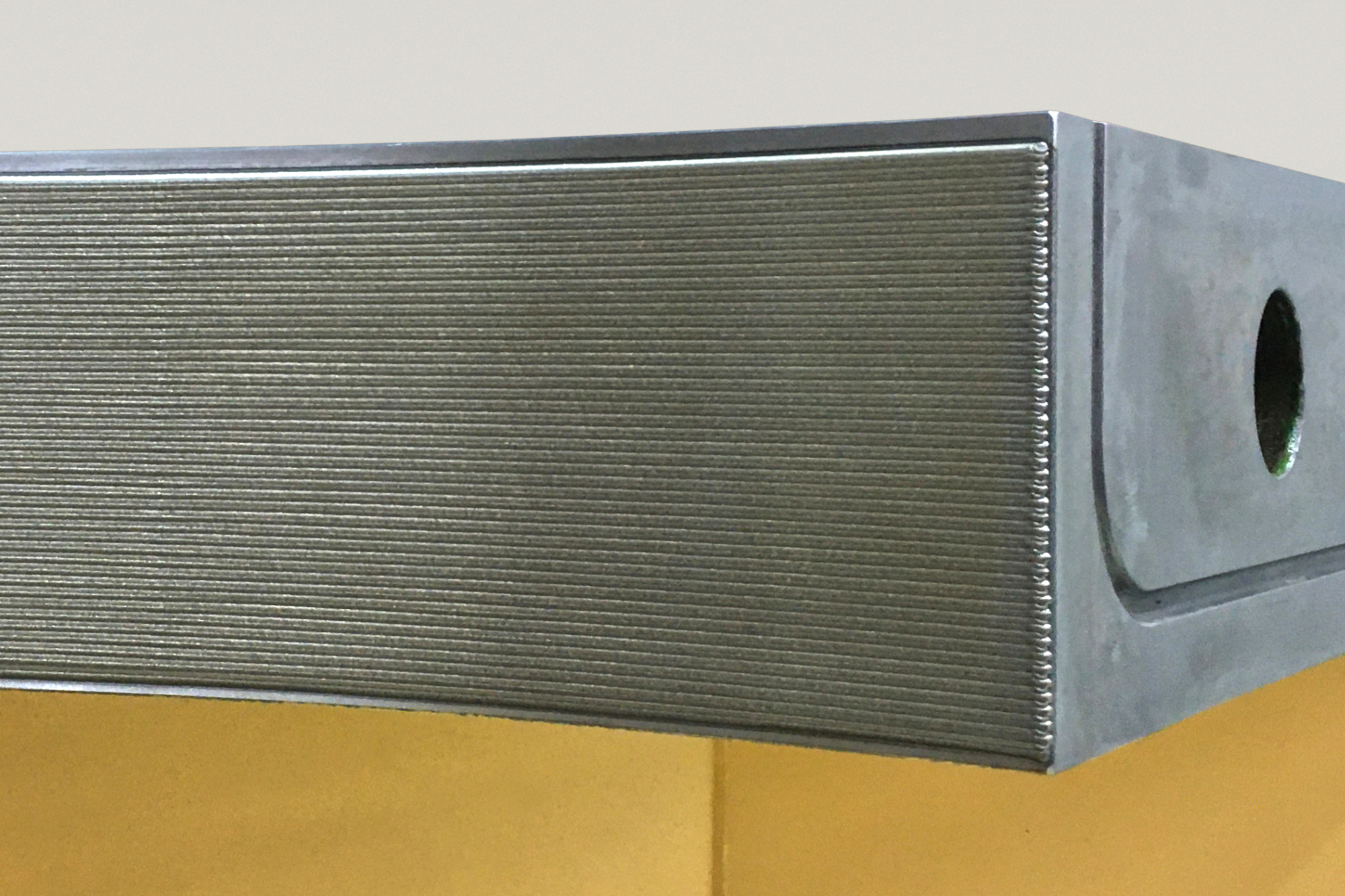

Finished bearing seat

Welding pattern as a meander track on a bearing seat with a track width of 3.8 and a layer height of 1.0 mm

-

Use as a stationary system

After the mobile repair work on site on the component, the laser system continues to be operated as a stationary 10-axis laser system.

Mobile laser processing

Advantages of ALOflex

Minimum size and space requirement

Minimum space requirement in the work area

Intuitive radio remote control

Operation from a clear, safe position

More flexibility is hardly possible

Use on crawler tracks, on components or stationary

Protection of components

Sensitive components are stored in the mobile media station

Maximum 10 kW laser power

10 kW laser power possible on the mobile laser system

Up to 10 synchronised axes

Up to 8 for mobile use and up to 10 synchronised axes for stationary use

Simple system operation

Simple operation thanks to predefined programme sequences

Sophisticated transport concept

Optimised transport dimensions for shipping by truck, ship or plane

Safe, safer, ALOprotect

Certified protective walls with protection limit (E86) of 13.8 MW/sqm

Modular system

Technical equipment

We design and manufacture your customised, mobile laser system for hardening, cladding (powder and wire) or CMT welding.

Connections

Electricity / Compressed air / Gas

Robot

Axes / Reach / Payload

Laser

Power

Optics

Hardening / Cladding / CMT welding

Peripheral

Positioner

Add ‑ on

Auxiliary and additional devices

Software

Auxiliary and additional devices

Customised equipment

System modules

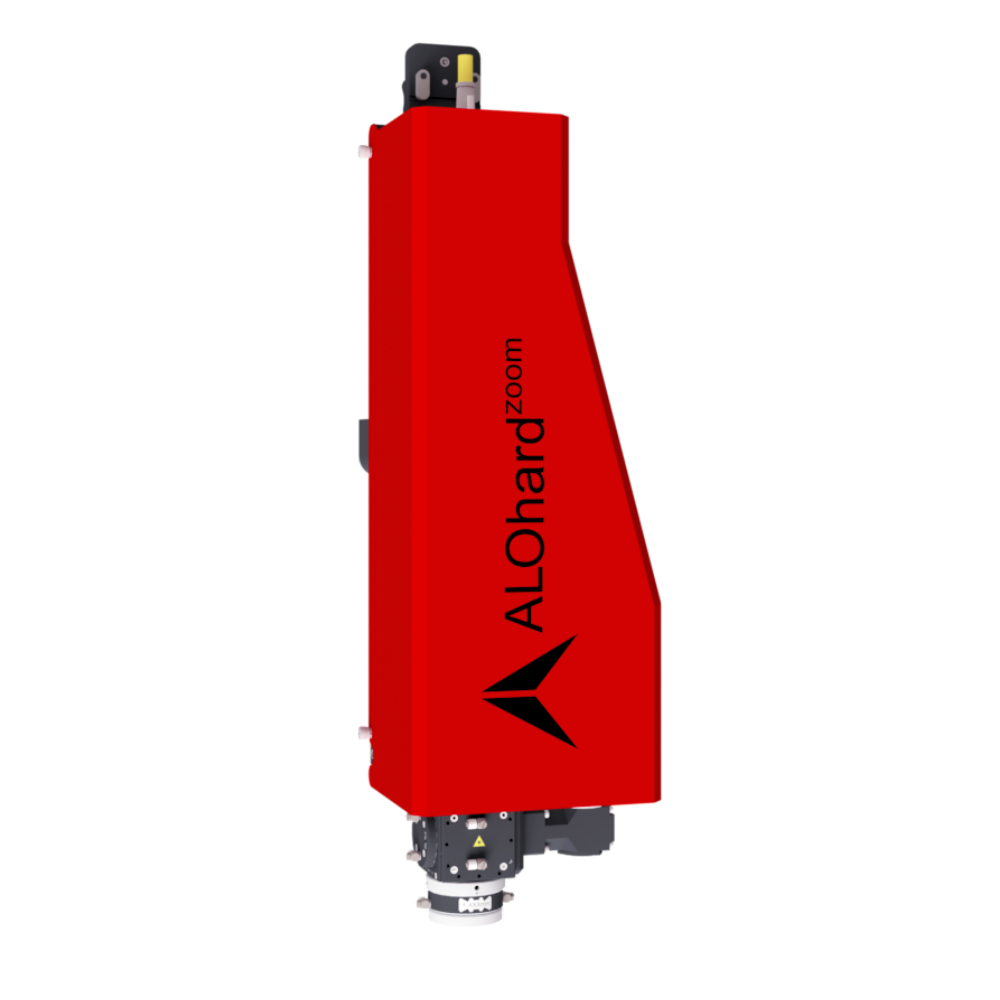

Processing optics for laser hardening

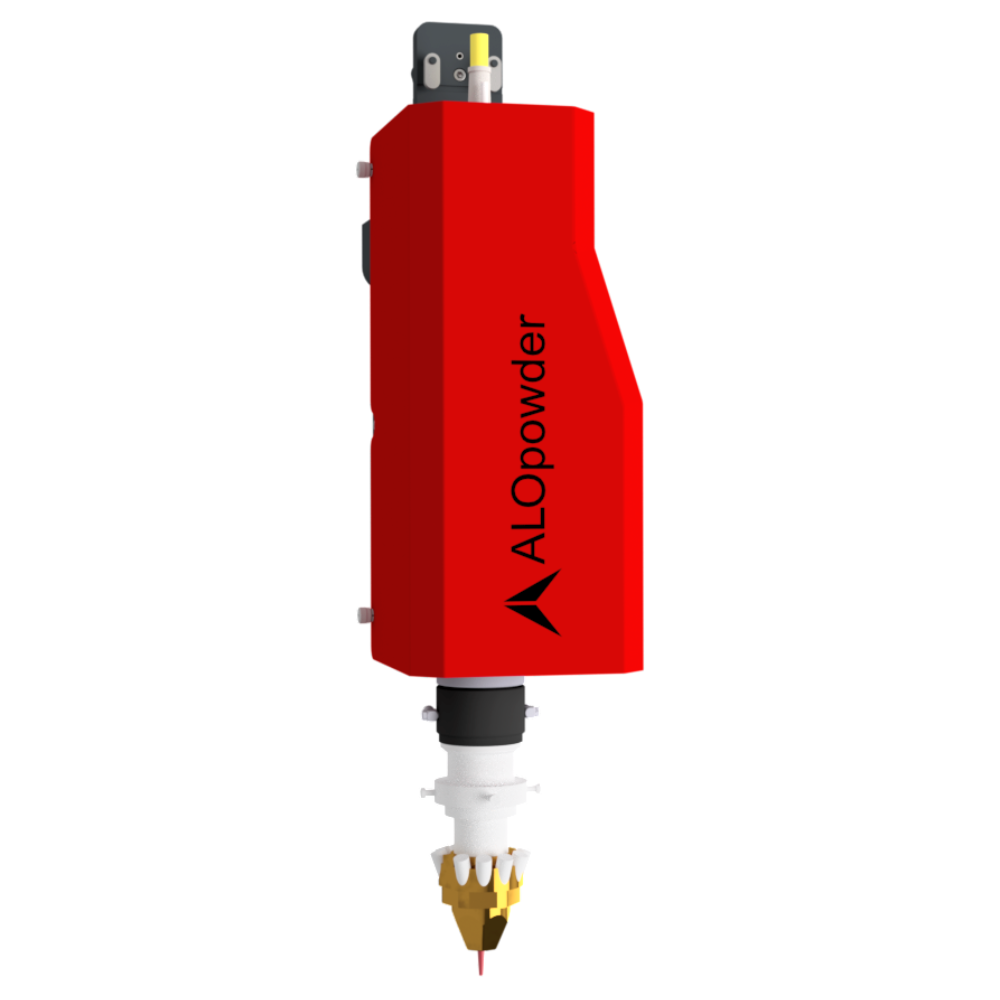

Processing optics for laser cladding

6-axis robot for 3D laser beam movement

Chassis with remote control for mobile systems

Turn-tilt table with 2 axes for positioning

Mobile media station for mobile laser systems

Mobile station for safety barriers and robots

Laser protection concept with laser safety barriers

Compact and flexible like no other!

We can do mobile.

The ALOflex mobile laser system is designed for a wide range of applications directly on the component at the customer’s site and can be expanded on a modular basis.

Our laser systems in the moving picture