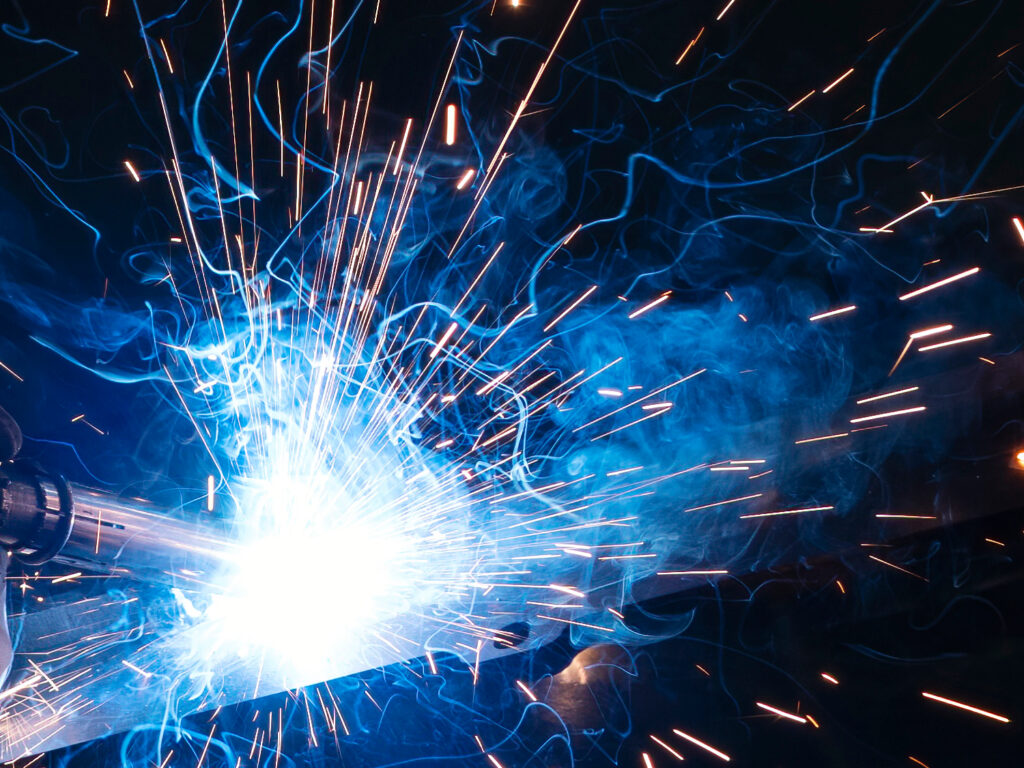

Arc welding

ALOarc

ALOarc

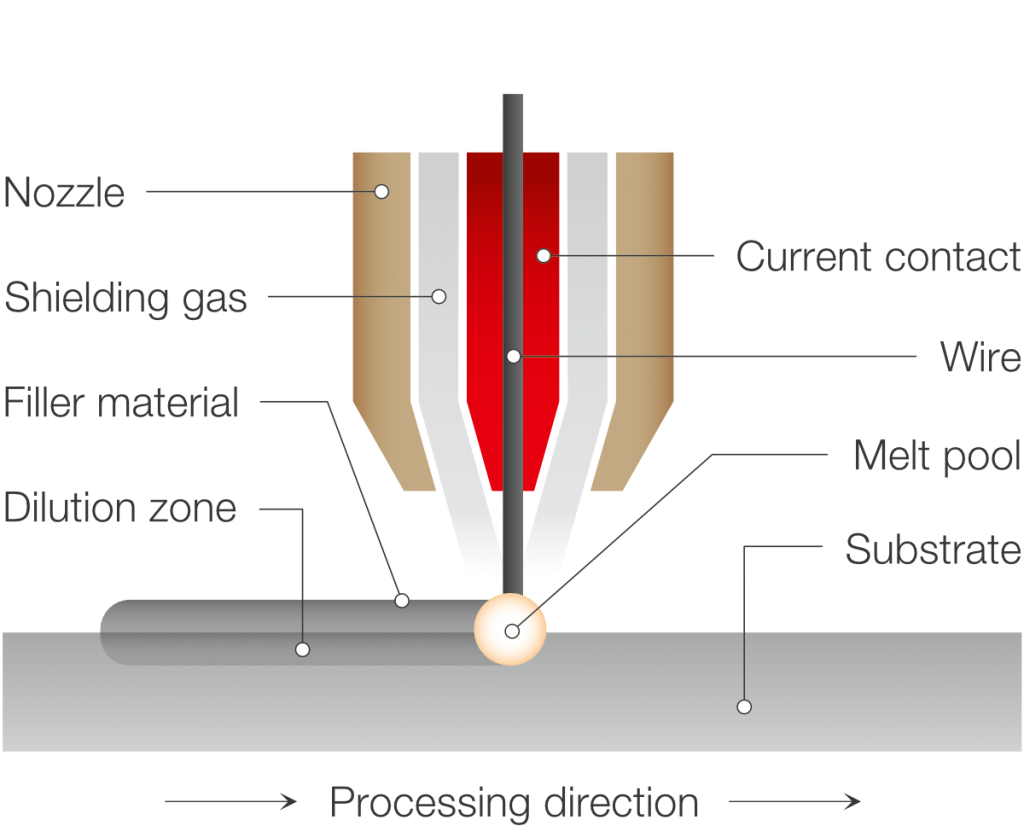

Arc welding and additive manufacturing

Arc welding is particularly suitable for high deposition rates and is used for cladding and joint welding. CMT welding is particularly suitable for additive manufacturing.

We will use this technology to further expand the production branch of additive manufacturing.

ALOarc

Sample components

Ready for all applications

Wire materials

Different types of laser cladding wires – including nickel-based, copper-based and iron-based alloys – ensure optimal cladding according to the desired requirements, such as wear resistance, corrosion resistance and temperature resistance.

- High toughness

- High corrosion resistance

- Ideal as buffer and filler material

- Flexible and economical

- Hardness up to 65 HRC

- Wear resistance due to W, V

- High corrosion resistance due to Cr, Ni

- Good sliding properties

- High corrosion resistance

- High resistance to cavitation

- Good sliding properties

- High corrosion resistance

Is additive manufacturing a must-have for you?

Let’s talk!

We’ll work with you to find the right solutions for your needs.

Our applications in moving images

Roll it – laser on

Laser hardening

Laser powder cladding

Laser wire cladding