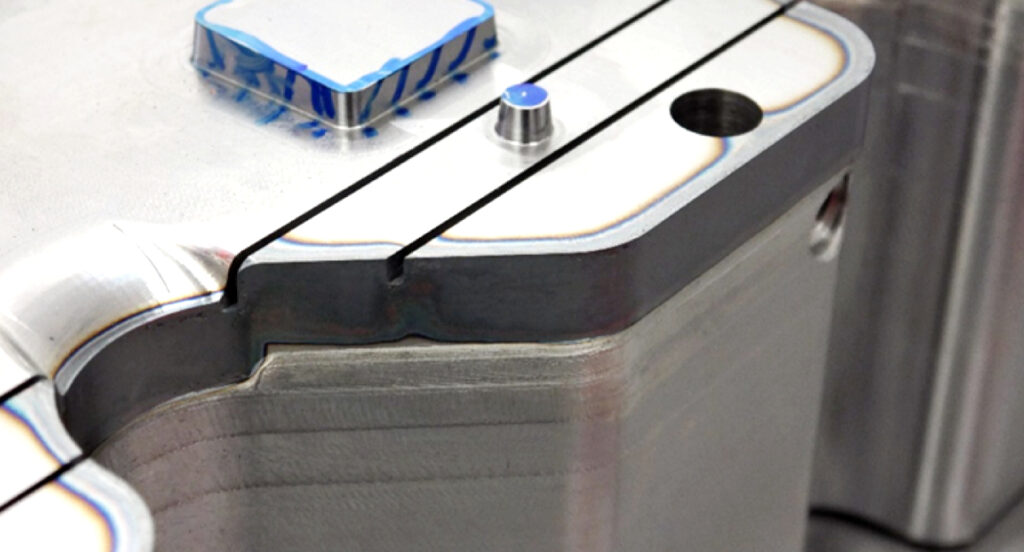

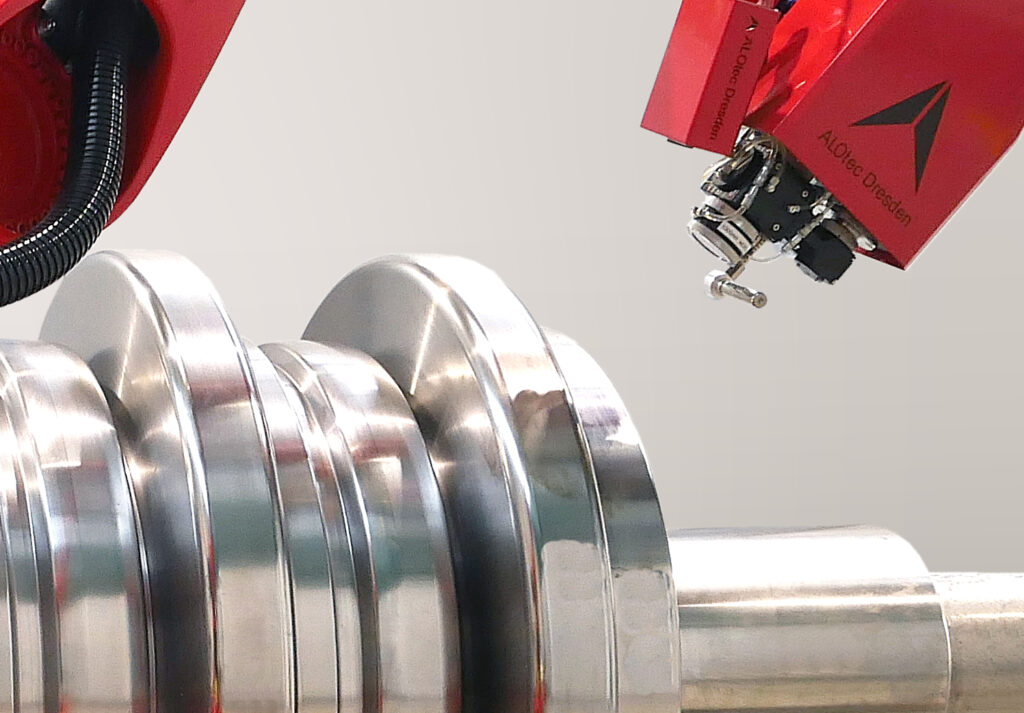

Laser hardening independent of the component geometry: radii, V-grooves, multiple steps or edges by means of dynamic, scan-like oscillating movement of an oscillating mirror.

Laser hardening with precision

ALOhard

ALOhard

Laser hardening

ALOhard laser hardening is a surface hardening process that generates maximum hardness values on the component surface with a very low energy input. This achieves a specific improvement in the wear behaviour of components.

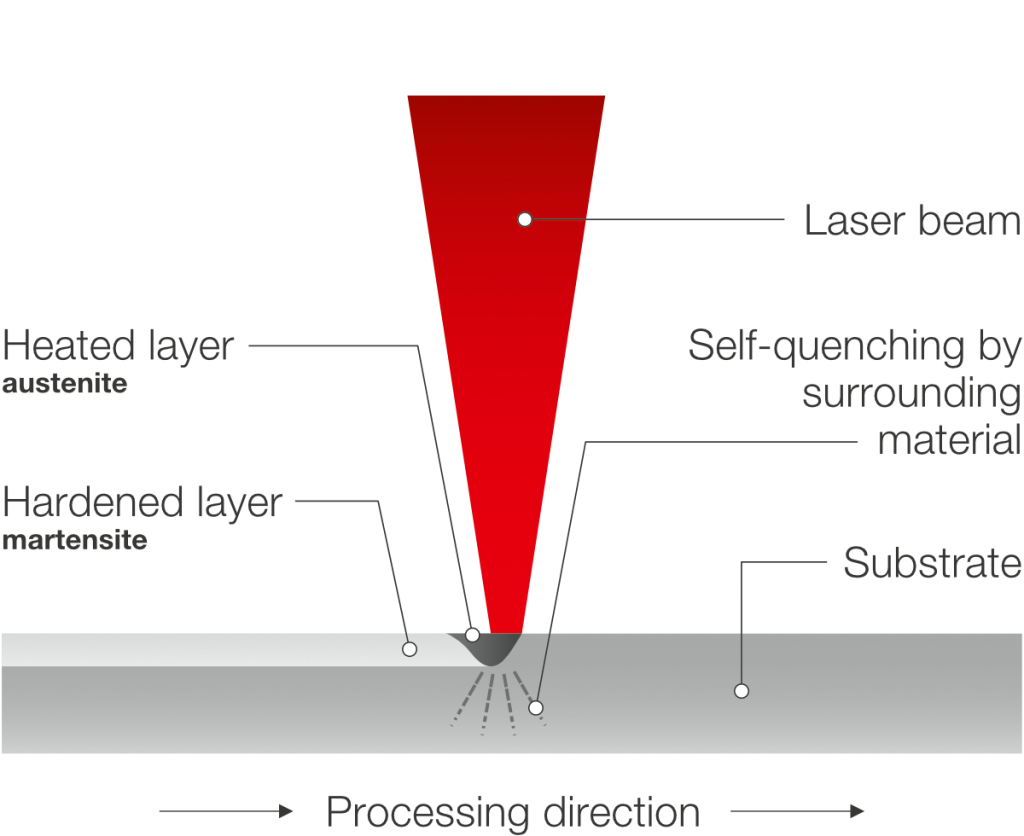

The laser beam briefly and precisely heats the upper area of the material above the austenitising temperature of the material used. This leads to an austenitisation front in the material. Due to the self-quenching via the volume of the component, no separate quenching medium is required and the rapid cooling leads to the formation of martensite.

Due to its technology, laser hardening is very environmentally friendly and conserves resources, and is particularly economical for small series and individual parts.

Technology for all component shapes

Processing optics for laser hardening

Depending on the geometry of the component, different processing optics ensure optimum surface hardness.

ALOhard

with fixed laser track width

ALOhardzoom

with variable laser track width

ALOhardscan

with dynamic laser beam guidance

From abrasion surfaces to gear racks

Laser hardening in use

ALOhard laser hardening is used for improving highly stressed, complex components. Maximum hardness values are generated on the component surface with low energy input. This achieves a specific improvement in the wear behaviour of highly stressed component surfaces. Laser hardening is used in industry, automotive, railway, mechanical engineering, tool and mould making, the oil and gas industry, mining, shipbuilding and agriculture.

Conveying screws Forming dies

Cutters & Cutting tools Machine beds

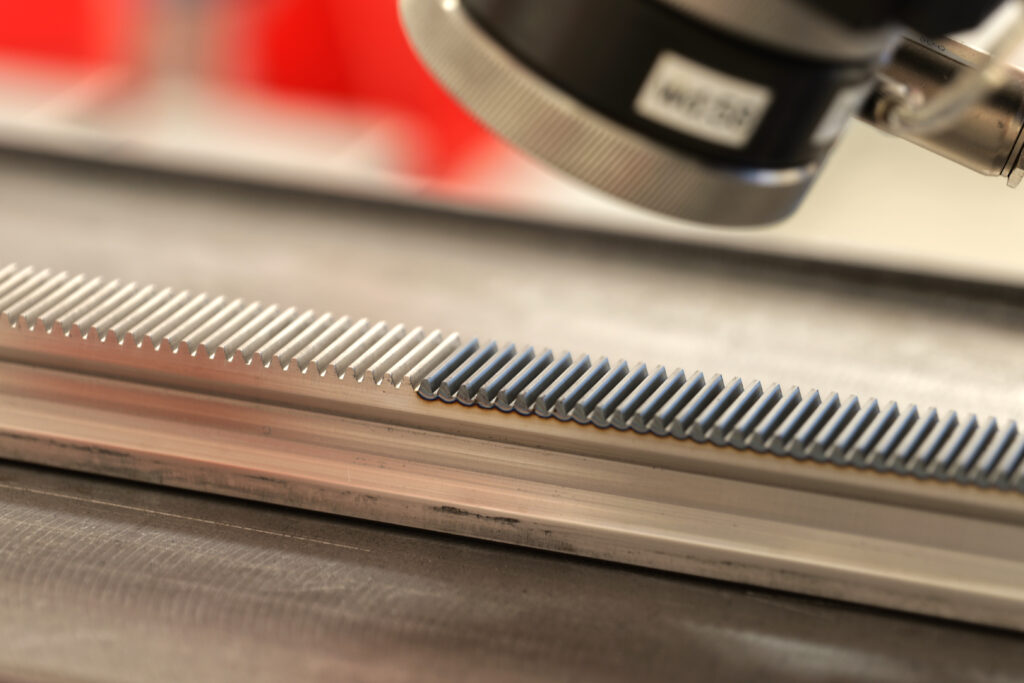

Rollers and shafts Gear racks

ALOhard

Sample components

-

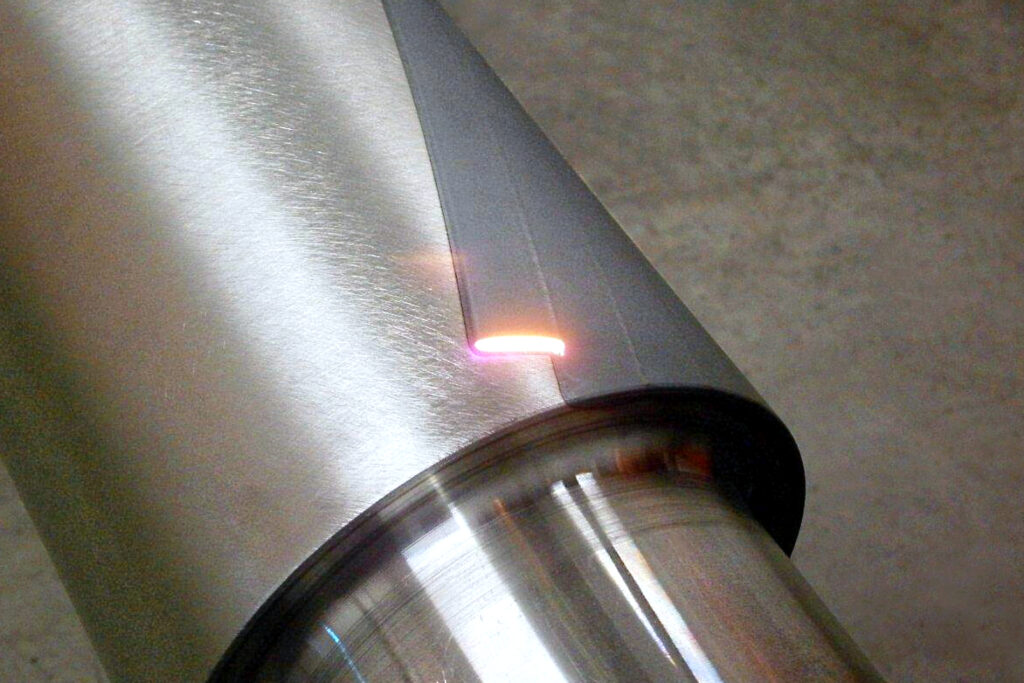

Hardening with dynamic optics

-

Turning part

- Base material: C45

- Surface hardness: 60 HRC

- Technology: ALOhard Laser hardening

-

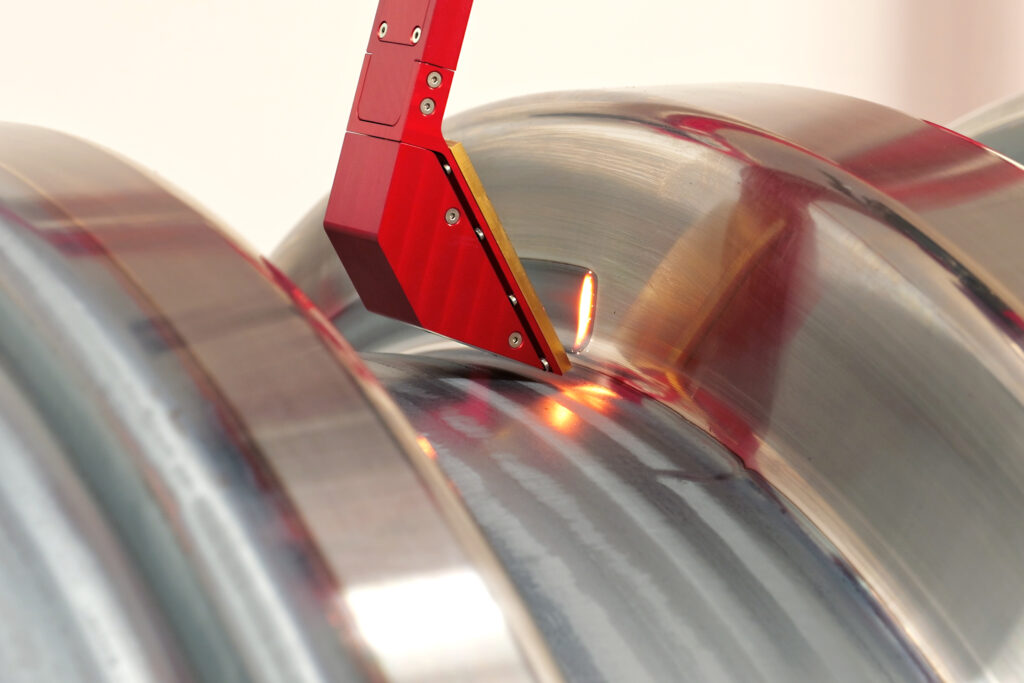

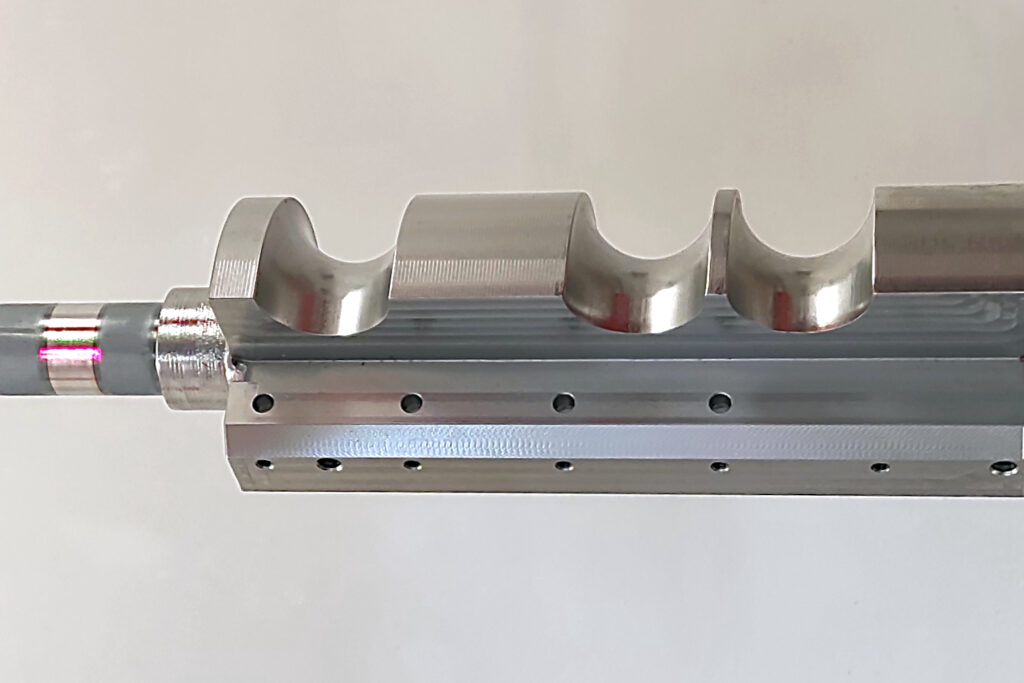

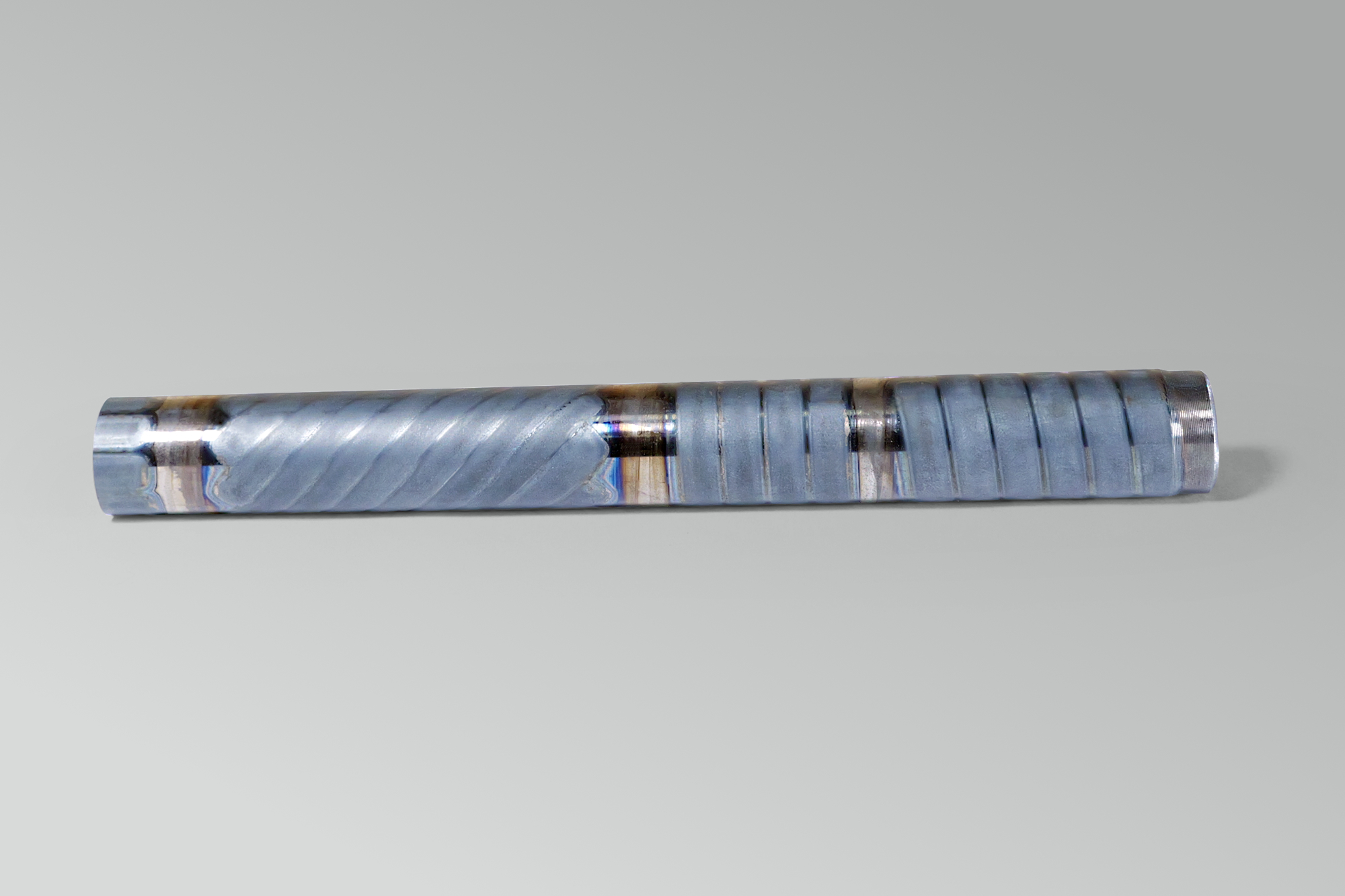

Shaft hardened by using macros

- Base material: C45

- Surface hardness: 57 HRC

- Hardening depth CHD: 0,5 mm

-

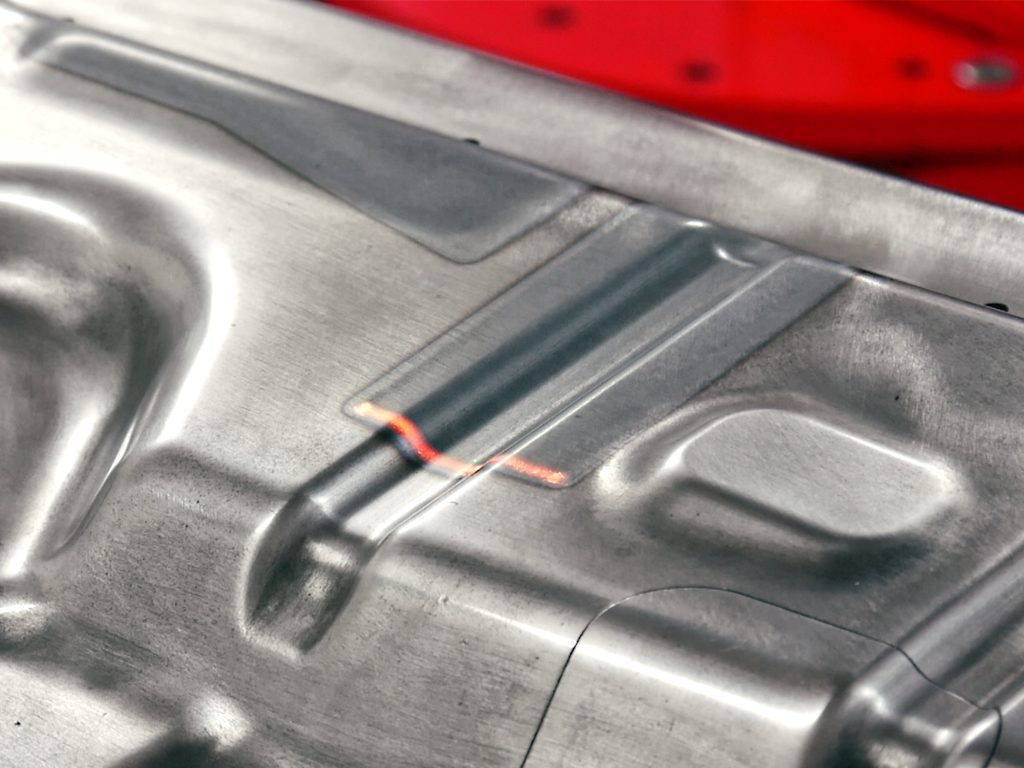

Forming die

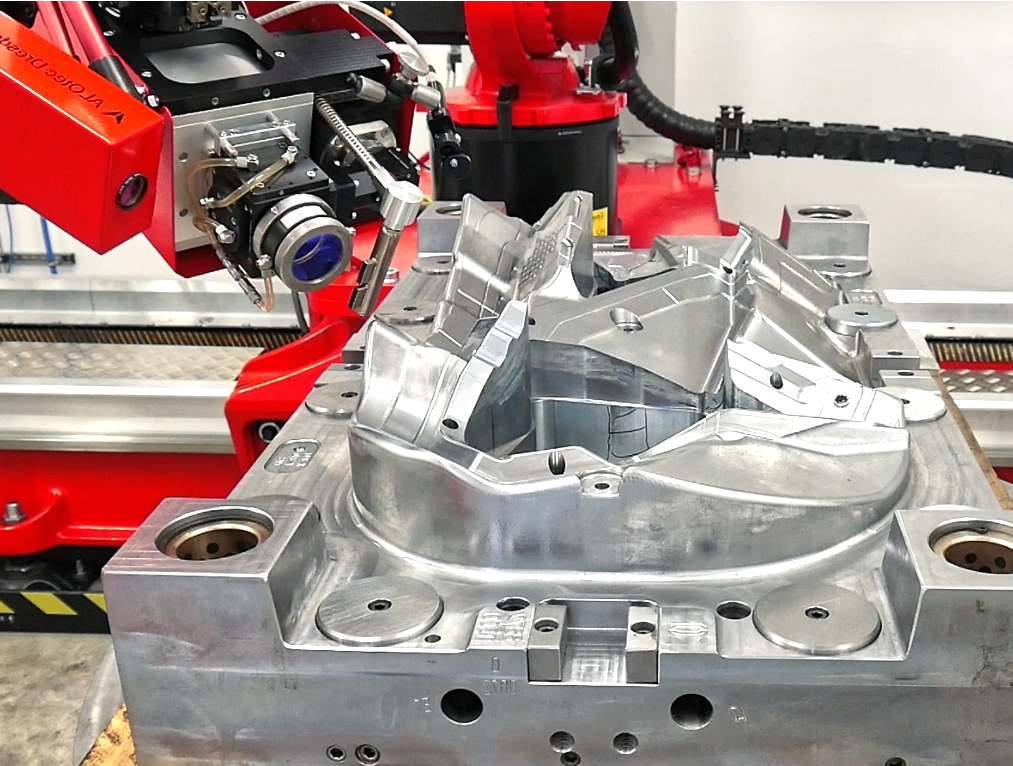

Laser hardening of a 3D freeform surface with ALOhardscan

-

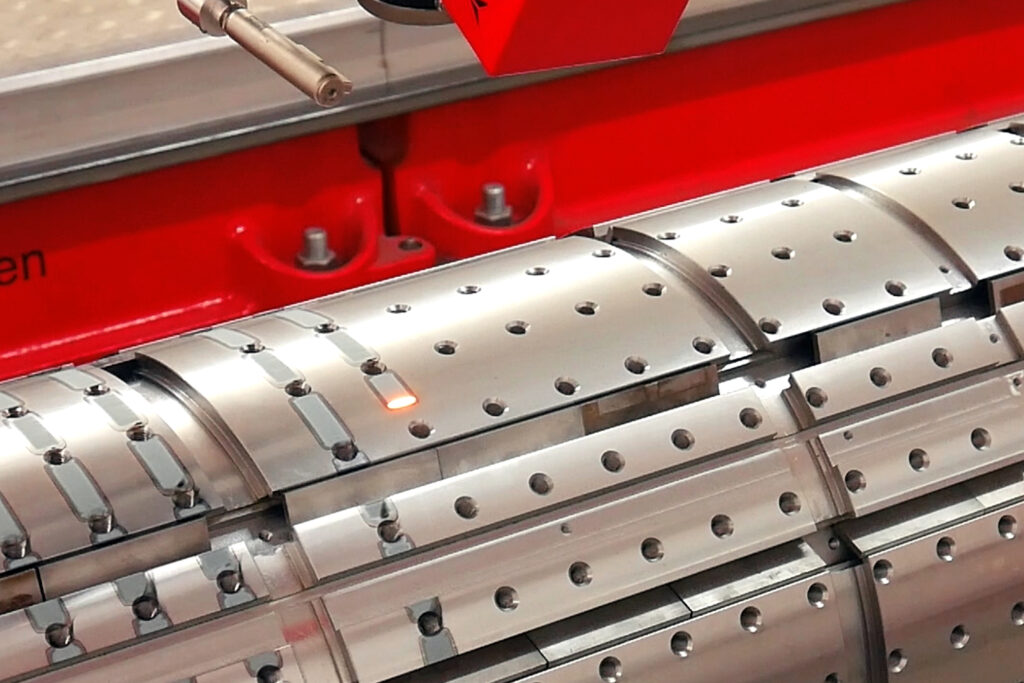

Bevel gear

Laser hardening of a bevel gear with ALOhardzoom for a variable spot size in the process.

ALOhard

Advantages of laser hardening

Laser power control for a homogeneous hardness profile

High surface hardness up to 65 HRC

Minimal distortion due to small heat input

Flexible shaping of the laser beam

Energy efficient and environmentally friendly

Time saving

Area rate up to 0.5 m²/h

No quenching media required

Small batches and single pieces

Your cost advantage:

We harden on your premises.

We offer ALOhard laser hardening and ALOpowder laser powder cladding directly on site at the component.

This eliminates transport and set-up times for the component as well as the associated costs and risks.

ALOhard in moving images