Positioning the WAAM system components

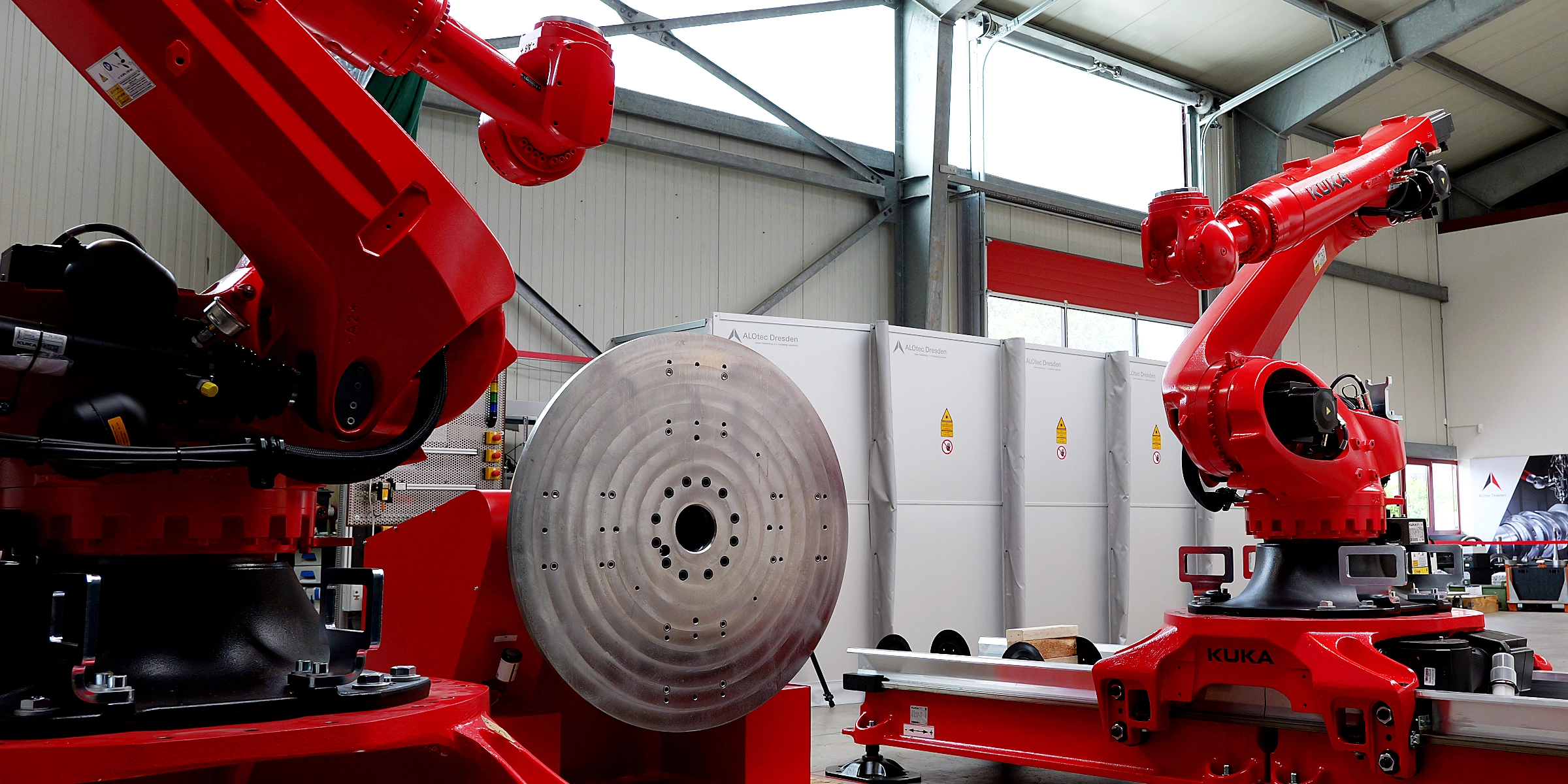

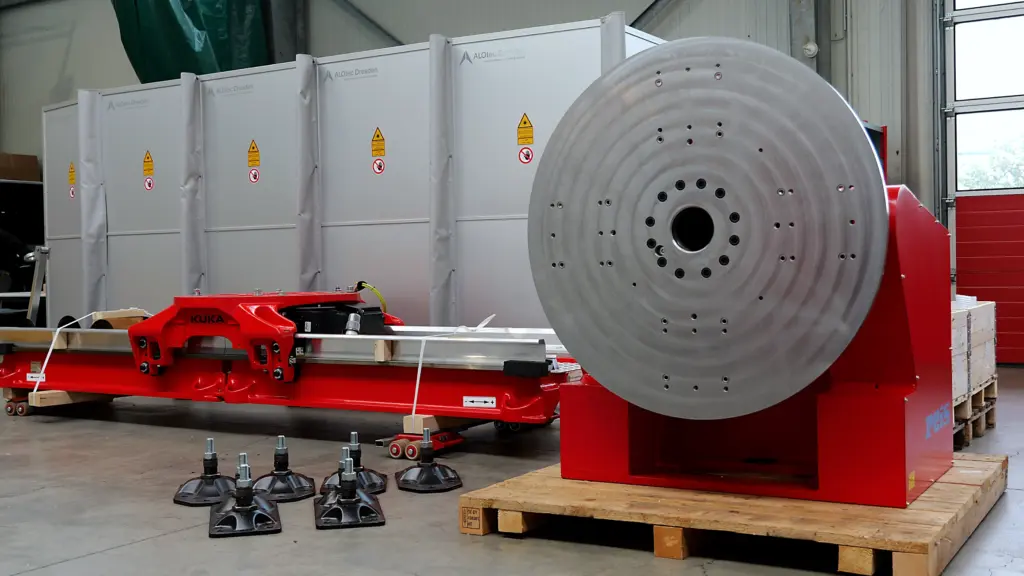

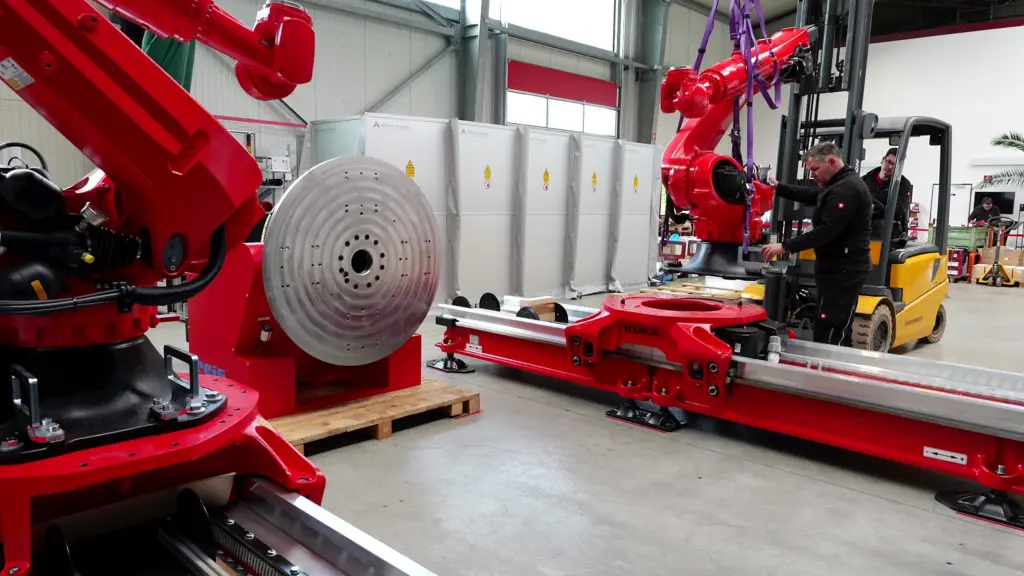

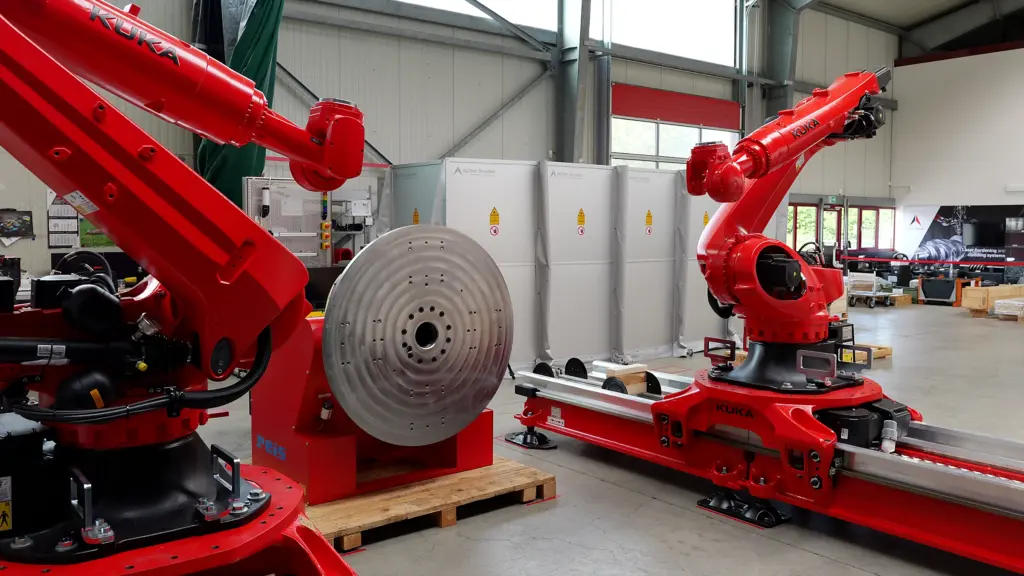

After the successful delivery, the main components were precisely positioned according to the system layout. The two 6-axis robots were mounted on their respective linear units and precisely aligned. The turn/tilt table was brought into the intended position and fixed in place. The control cabinets and other system components were also positioned accordingly.

Particular attention was paid to the exact alignment of all components in order to ensure the subsequent synchronization of the 16 axes. The parallel arrangement of the linear units and the precise positioning of the turn/tilt table form the basis for the collaborative operation of the robots in master-slave mode.

This precise assembly marks another milestone in the construction of the WAAM robot system for the the Chair of Joining and Welding Technology at BTU Cottbus.