Laser hardening for TAKRAF: Gears for use in open-cast mining

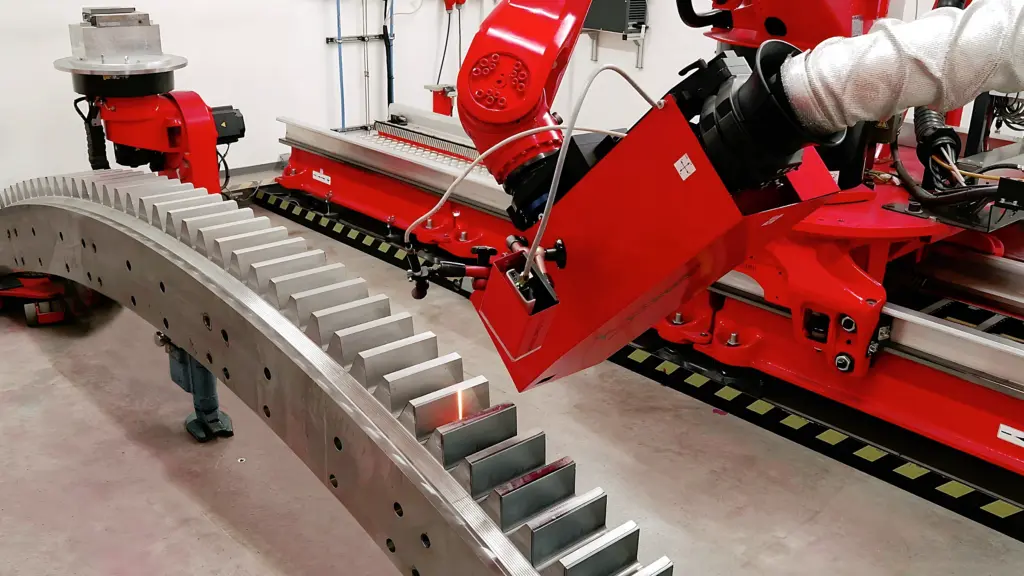

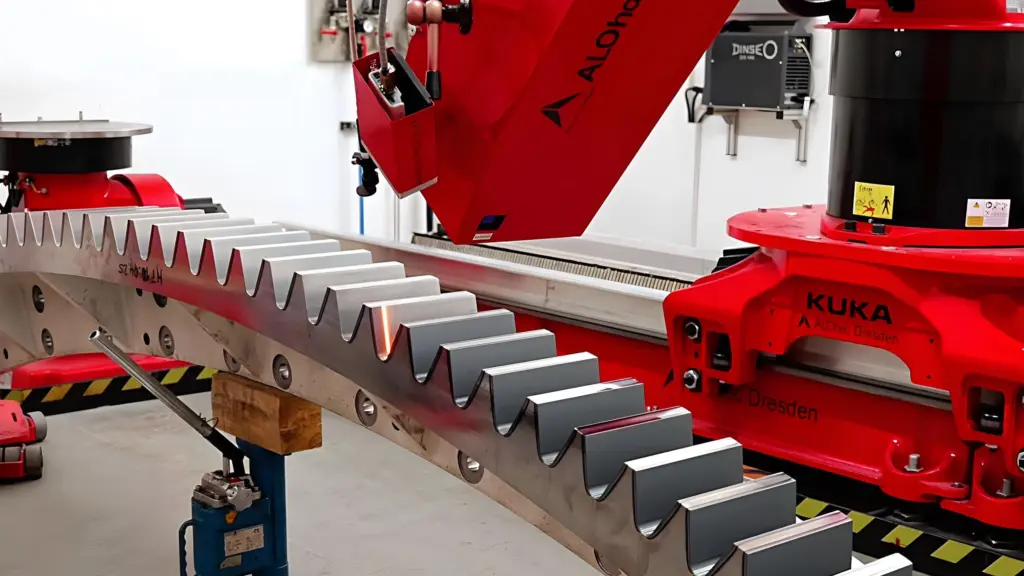

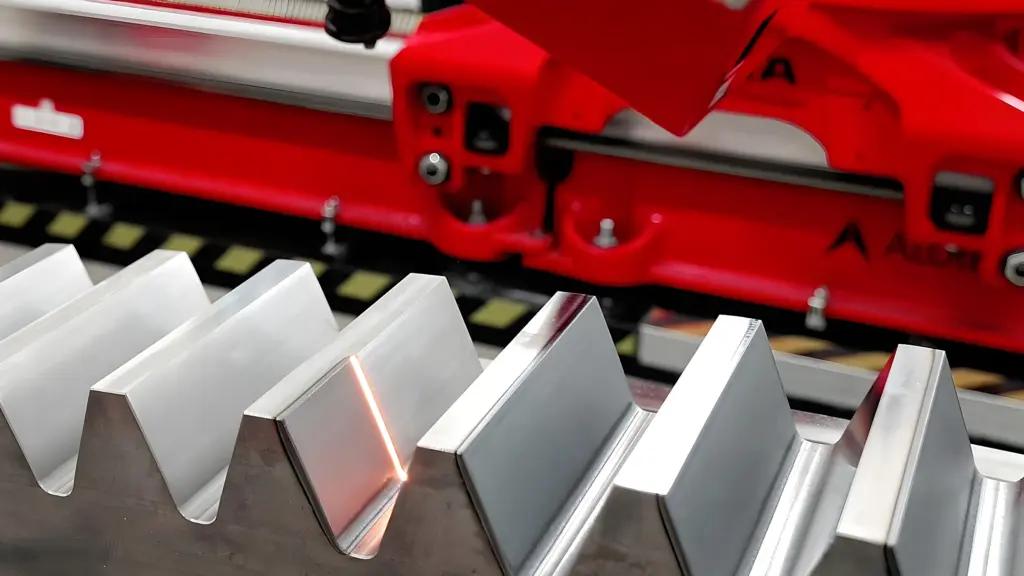

Surface hardening of the tooth flanks of 16 gear segments for TAKRAF – one of the leading suppliers of mining technology. The finished gears have a diameter of 9 meters and consist of eight segments, which will later be used in bucket wheel excavators in opencast lignite mining near Neyveli (India).

![]() The task:

The task:

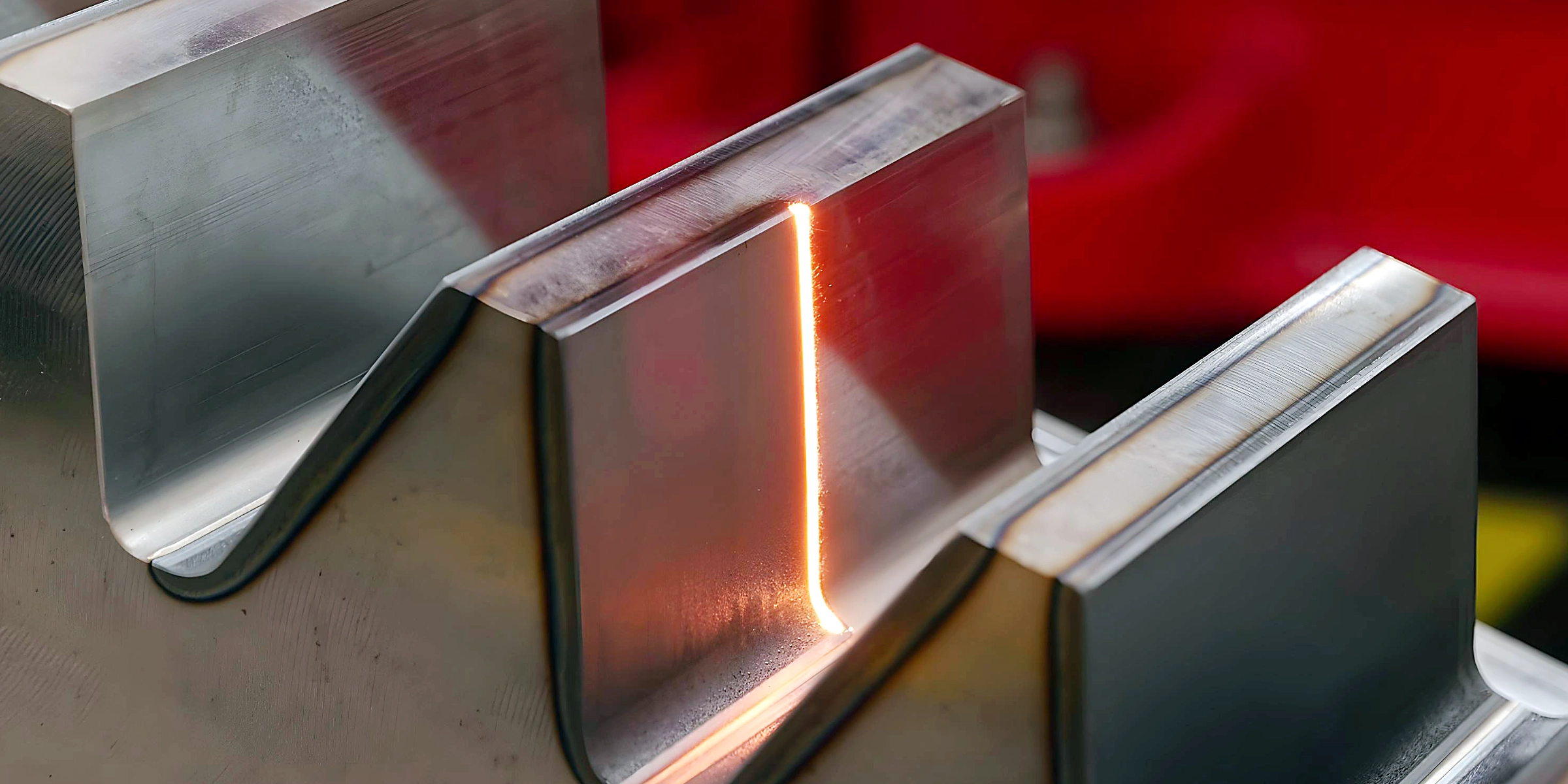

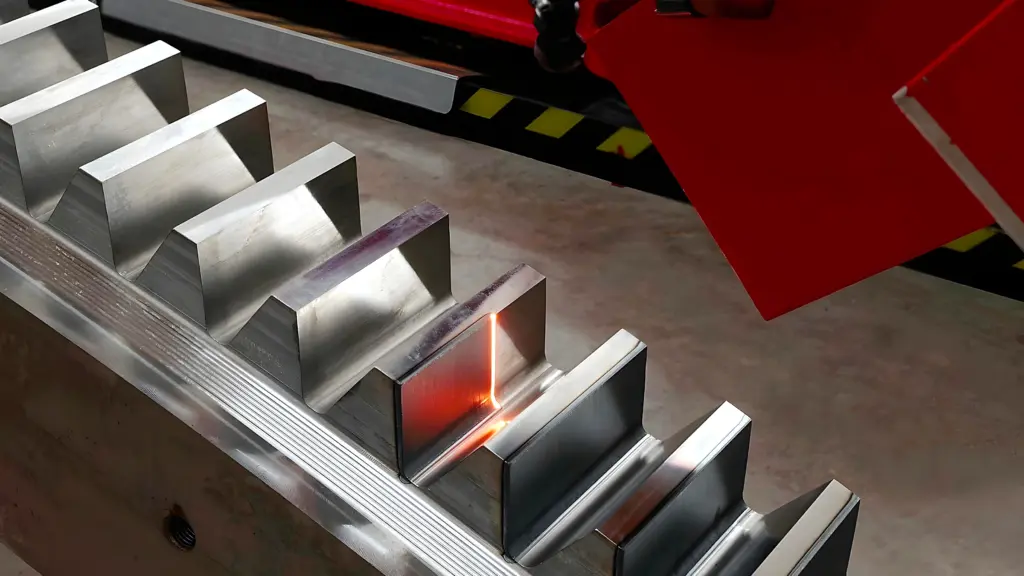

Each segment weighs 950 kg, is almost 4 meters long and has 38 teeth. The material: 42CrMo4. The goal: an extremely hard and wear-resistant surface on the tooth flank and tooth base with a tough component core.

![]() The solution:

The solution:

Laser hardening using scan optics. This surface hardening allows an entire tooth flank to be hardened in just one track without creating a tempering effect – precisely, reproducibly and with minimal distortion. The result is hardness values of up to 55 HRC with a hardening depth of around 1 mm.

![]() The advantages of laser hardening:

The advantages of laser hardening:

- Homogeneous hardness and no tempering effect thanks to scan optics

- No heating of the entire component as with oven hardening

- Minimal distortion – hardly any rework required

- Precise positioning and simple system operation thanks to macros

![]() Conclusion:

Conclusion:

The laser-hardened segments are assembled into a ring gear and then installed in bucket wheel excavators. They are a key component for the reliable rotation of the uppercarriage during operations under extreme conditions – and an example of how modern laser technology from Dresden makes international mining more efficient and economical.

We have created a video about wear protection for gear rim segments using laser hardening and published it on YouTube:

Would you like to find out more about wear protection using laser hardening? We look forward to providing you with comprehensive advice.