Currently under construction

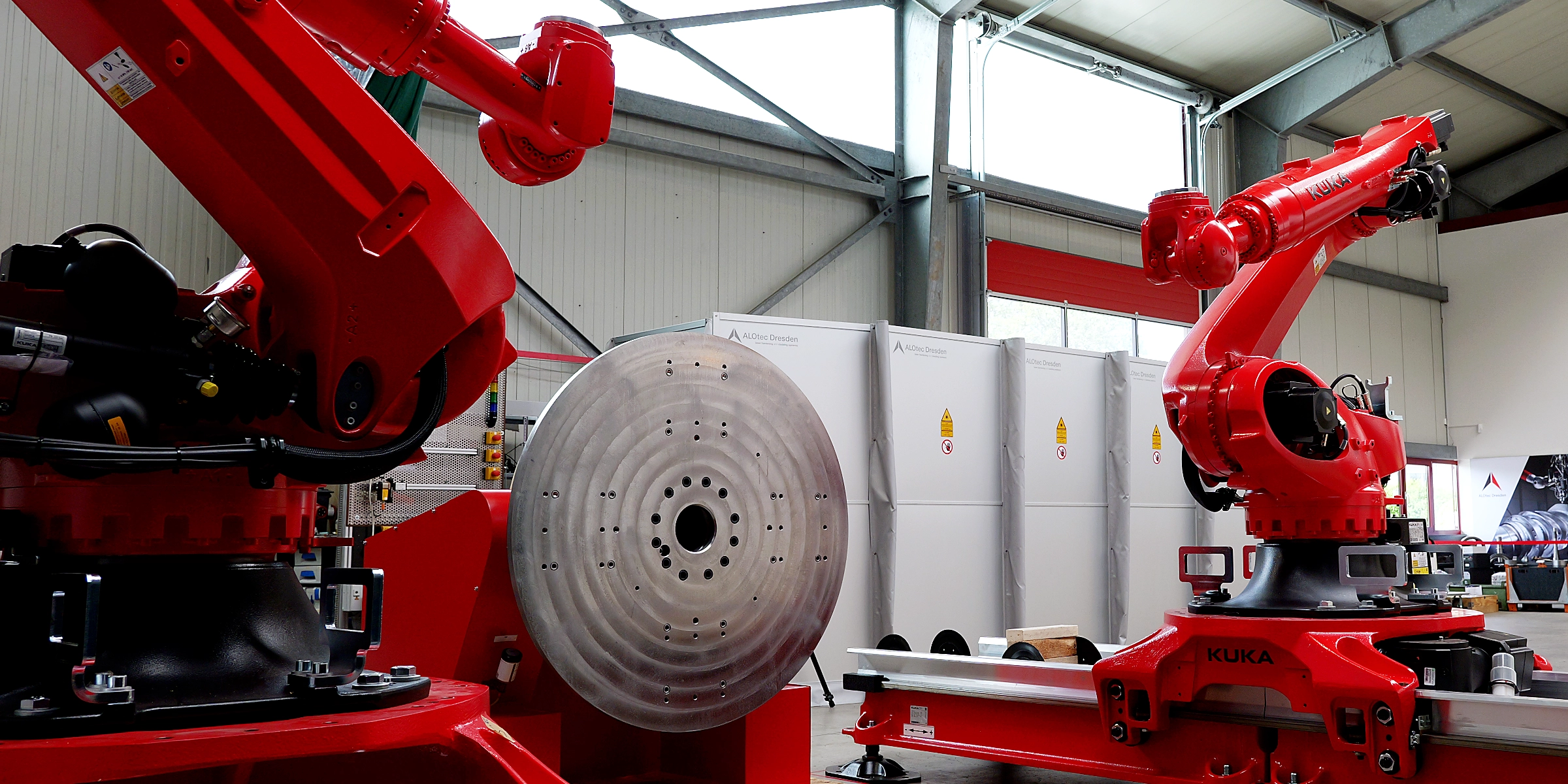

WAAM system

Currently under construction

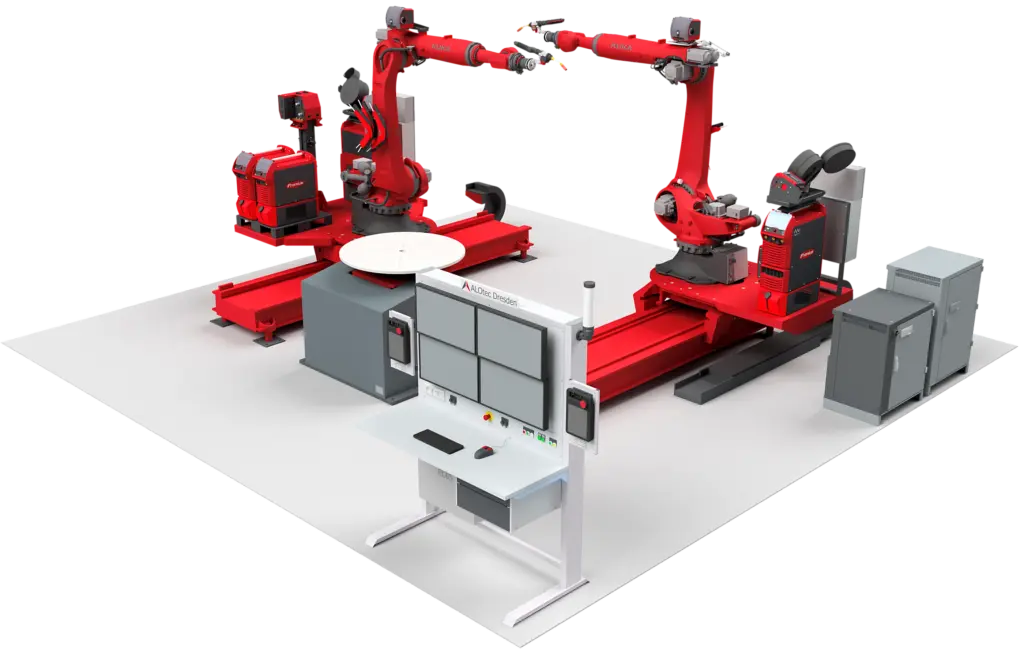

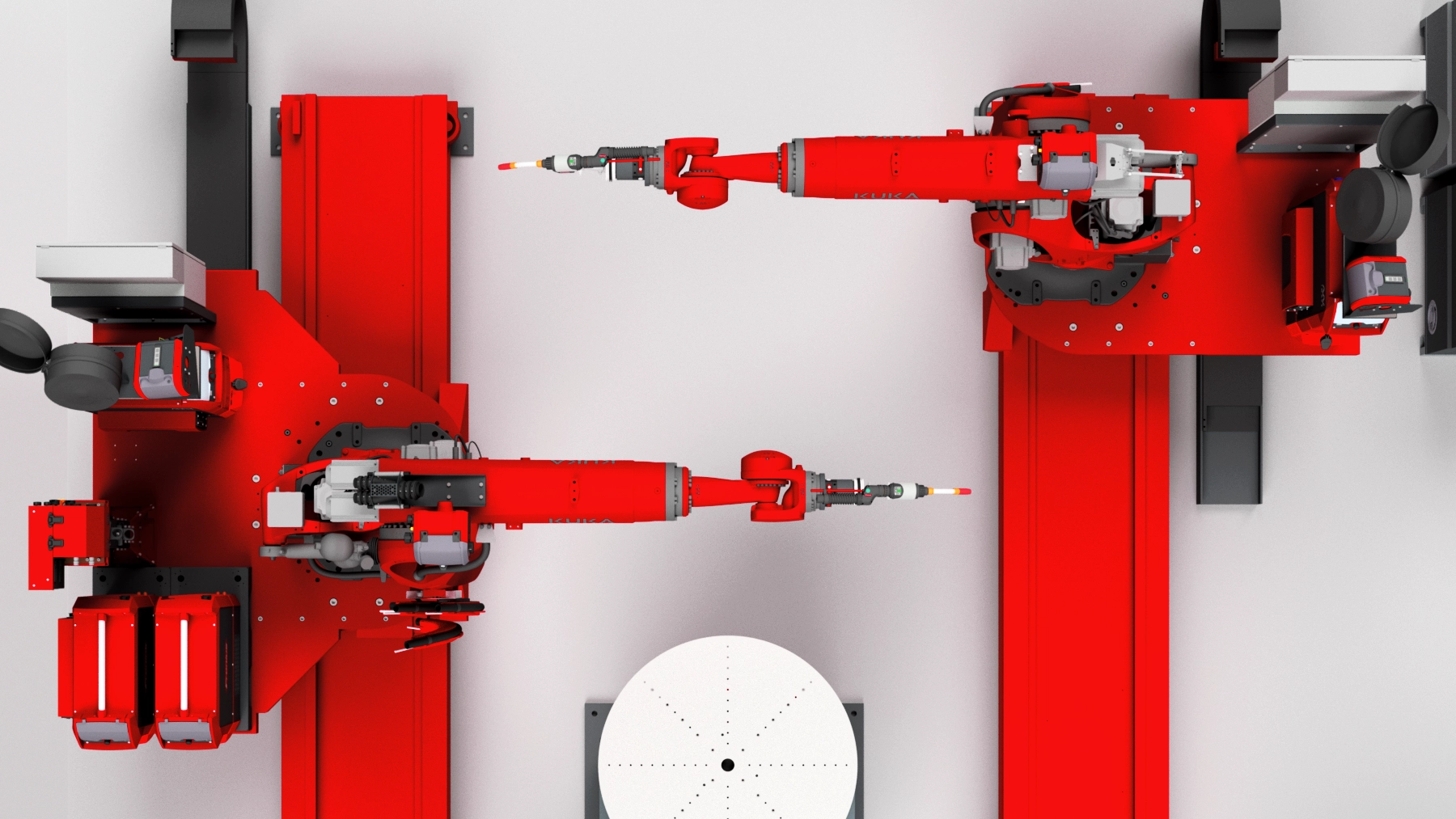

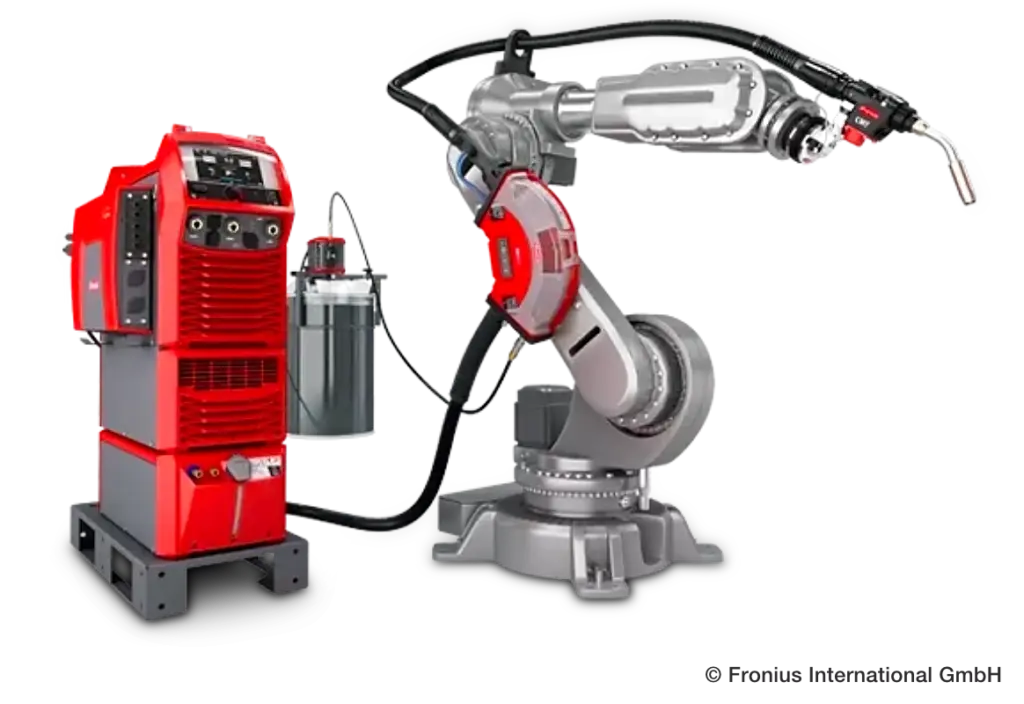

Collaborative WAAM robot system

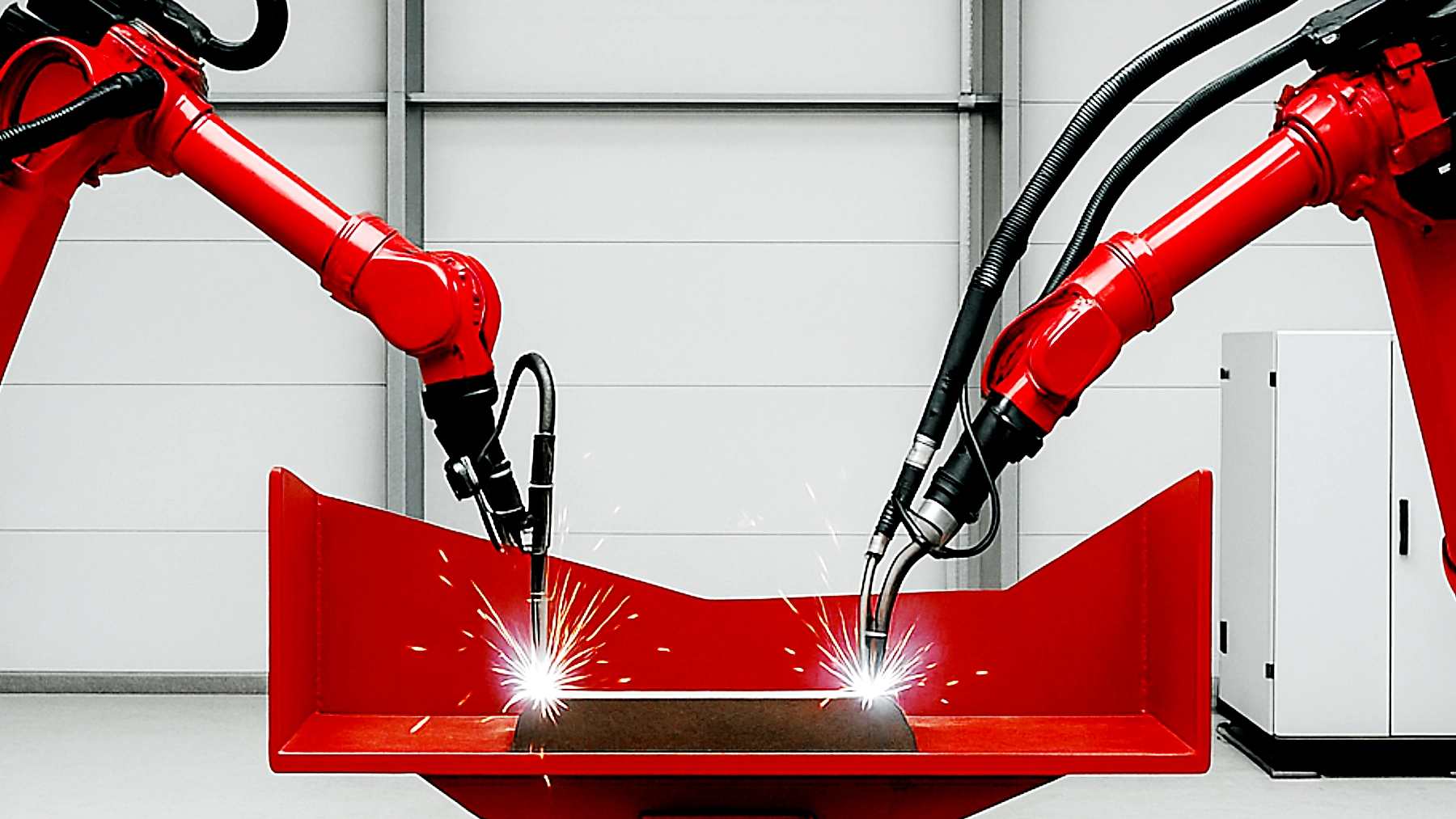

Two robots, one goal: In this stationary system – with a total of 16 synchronized axes – two welding robots work simultaneously on one workpiece – for additive manufacturing and advanced coating using WAAM (Wire Arc Additive Manufacturing).

Equipped with the latest Fronius technology – two iWave systems for automated welding solutions and a TPS/i TWIN system with PMC and CMT function – a pioneering system for researching and testing new processes and applications is being created for the Chair of Joining and Welding Technology at BTU Cottbus.

Follow the construction of the system

Creation live

Elements of the robot system at a glance

Technology in detail

This robot system combines precise movement, modern welding technology and coordinated system control. Two collaborating robots with a total of 16 synchronized axes, powerful WAAM processes with Fronius technology and a sophisticated master-slave principle make it the ideal platform for future-oriented applications in additive manufacturing and coating.

2 collaborating

robots

Two collaborating 6-axis KR120 R3100 robots work precisely together with a reach of up to 3100 mm and a payload of 120 kg – controlled by KRC ROBOTstar.

16 synchronized

axes

The system controls 16 axes simultaneously – two robots, two linear units and a turn/tilt table work in perfect synchronization.

Master-slave

operation

One robot sets the movements (master), the other follows (slave) – so both work in perfect coordination on a common component.

iWave systems

for automated

welding solutions

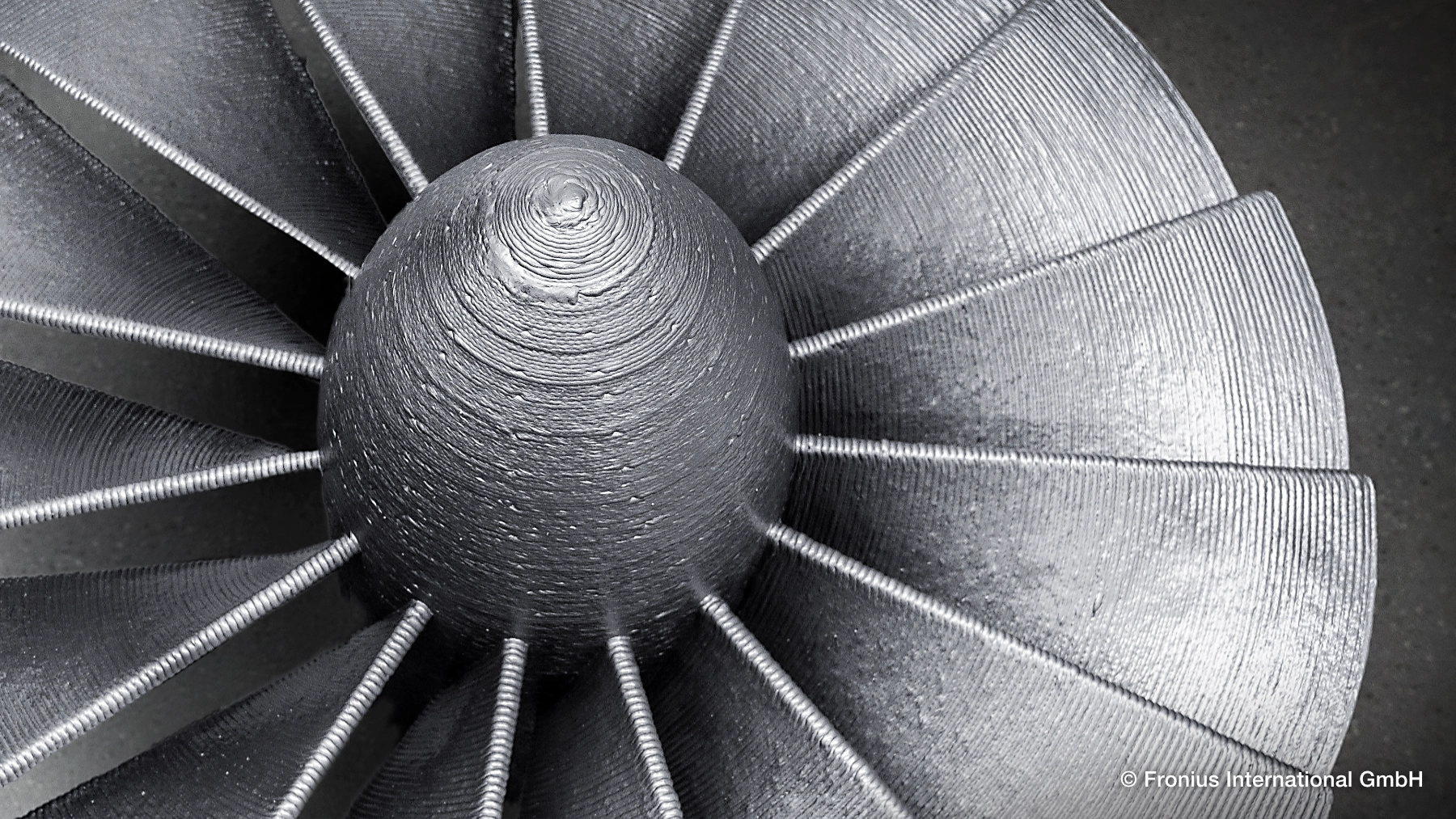

Additive manufacturing process for metal 3D printing enables fast, cost-effective and precise component production.

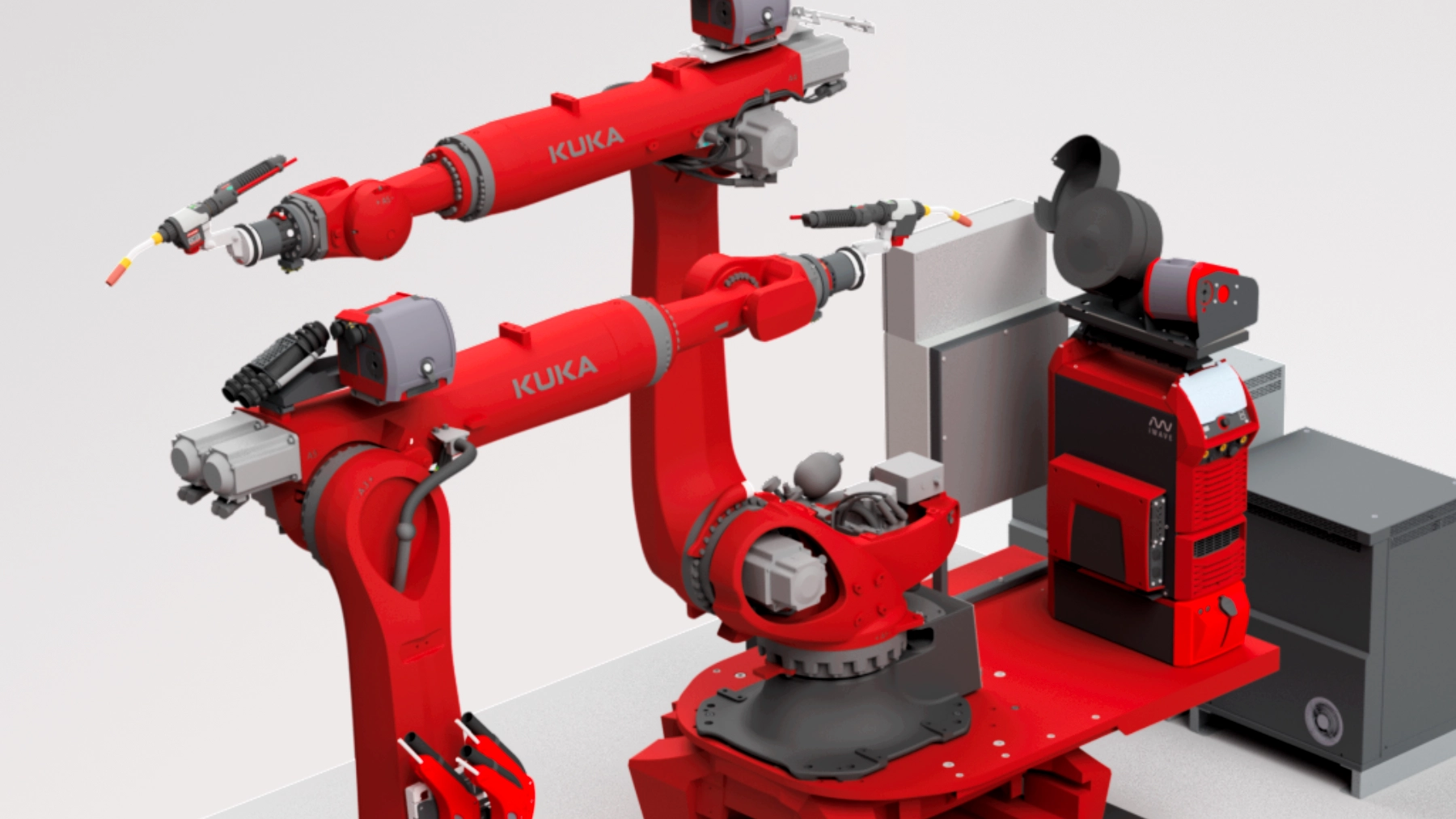

TPS/i TWIN system

with PMC and

CMT function

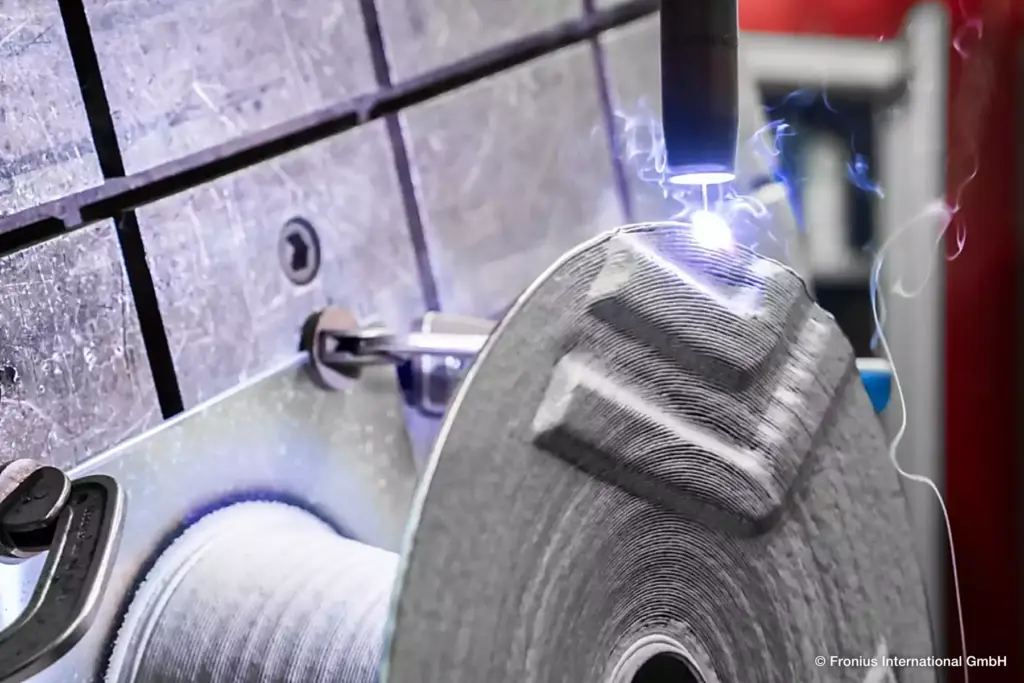

Arc deposition welding (WAAM) with PMC (Pulse Multi Control) and CMT (Cold Metal Transfer) using TPS/i TWIN system from Fronius.

Additive

manufacturing

and coating

For research into new applications and processes in the fields of additive manufacturing and coating.

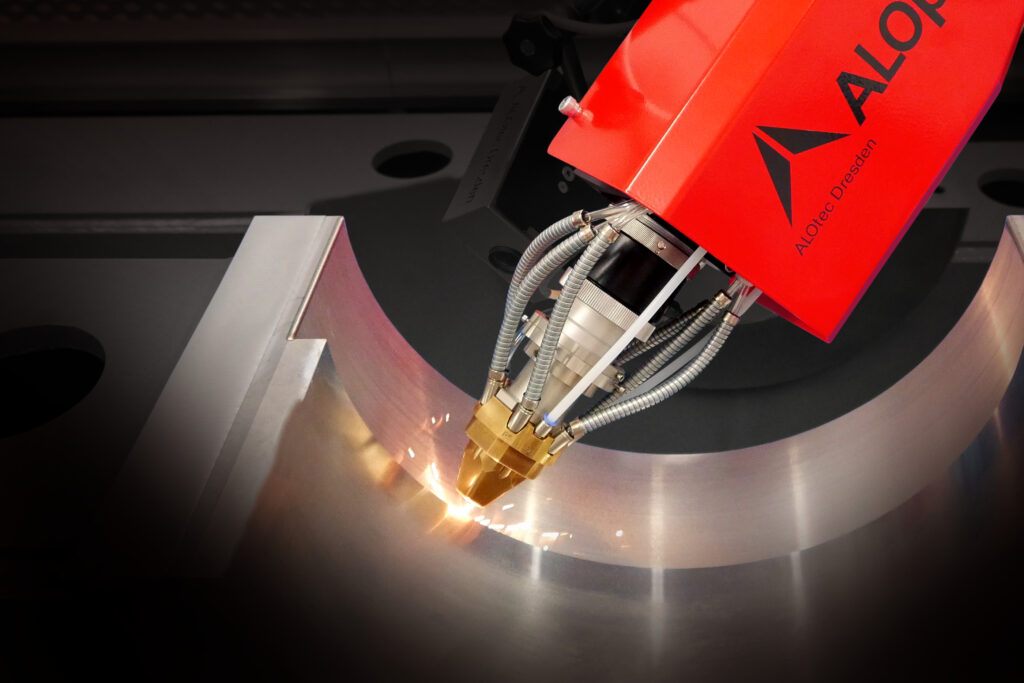

ALOarc welding process

Processing heads for WAAM

TPS/i TWIN system

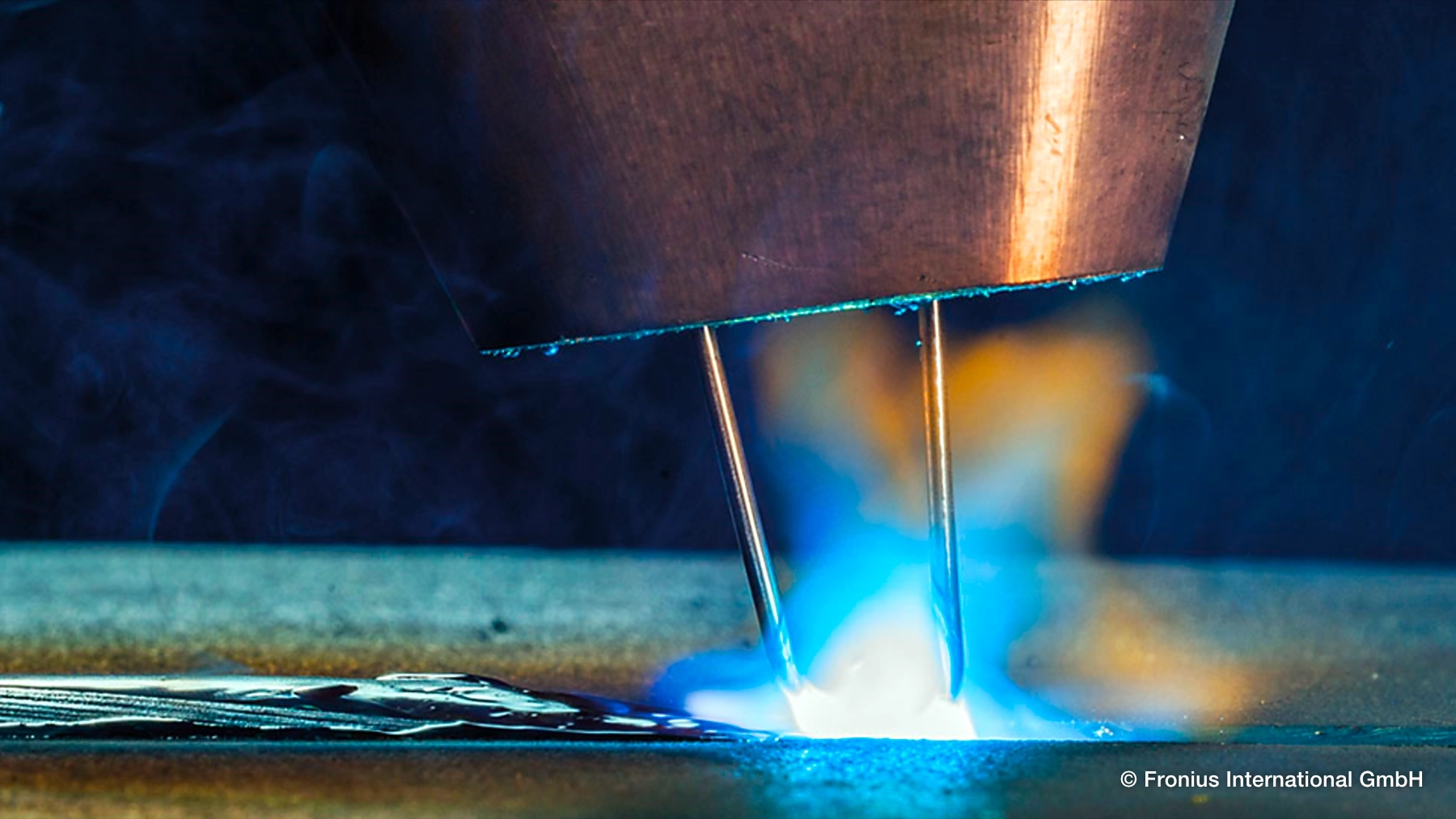

The TPS/i TWIN system from Fronius enables arc welding with two wire feeds and two power sources simultaneously. This enables higher deposition rates to be achieved – ideal for large-volume components or rapid deposition of layers.

PMC (Pulse Multi Control)

Intelligent welding process from Fronius, in which current is injected in pulses. This produces high-quality weld seams at high welding speeds.

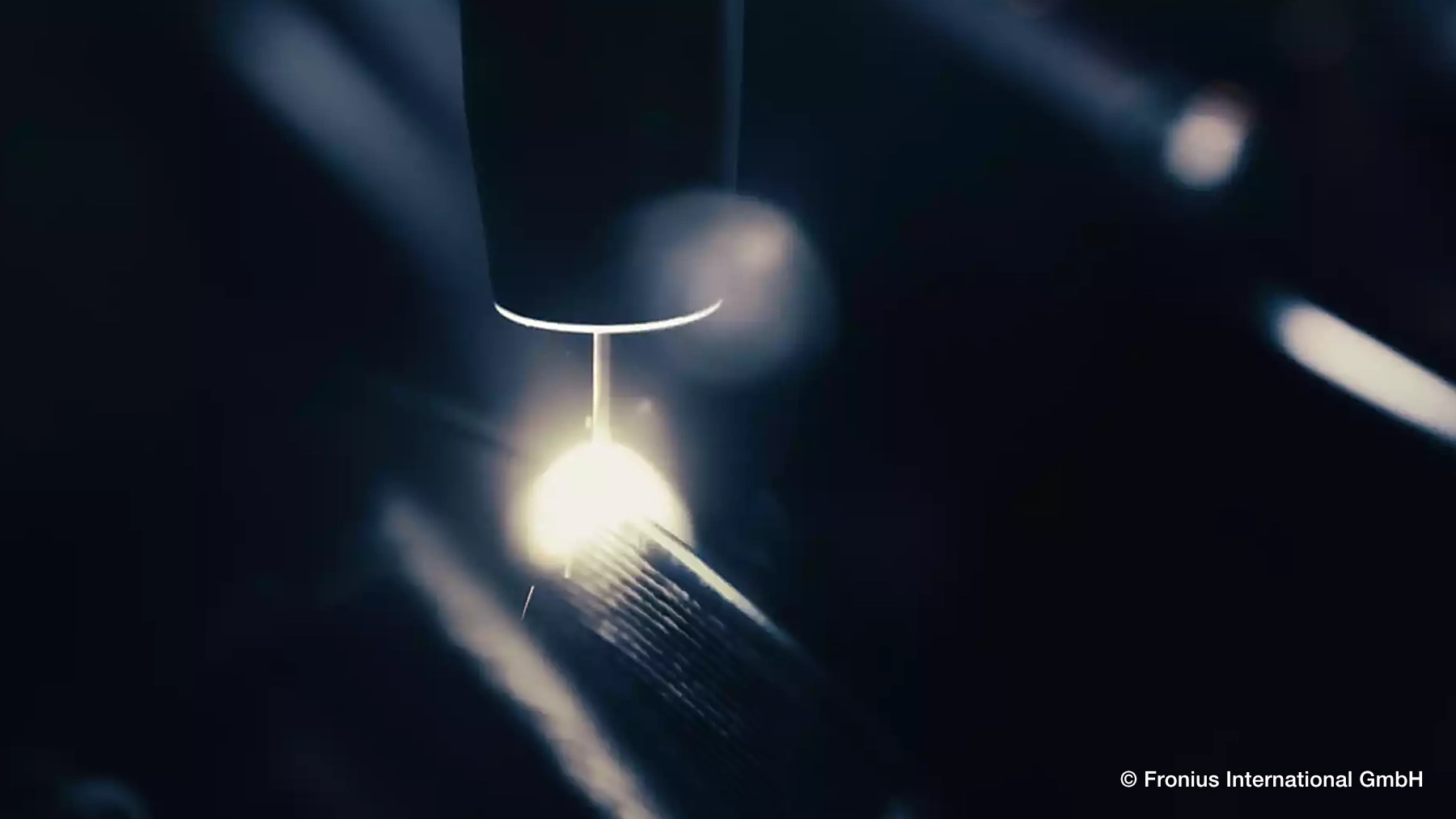

CMT (Cold Metal Transfer)

The wire moves back and forth during the welding process. The result: a spatter-free material transition.

iWave for automated welding solutions

The wire and arc-based CMT process enables complex geometries and a high degree of flexibility in component design with a high deposition rate. This makes Fronius Additive particularly suitable for prototype construction and small series.

CMT Additive Pro

The CMT process is extremely stable thanks to its revolutionary reversing wire movement, making it perfect for additive manufacturing.

The “CMT Additive Pro” characteristic curves have been specially developed for additive manufacturing. A uniform layer structure, reproducibility and other challenges can be mastered with ease.

Additive manufacturing and coating

Shaping the future with WAAM

The system is used in a scientific environment – for the development of new applications and processes in additive manufacturing and in the coating sector using WAAM. This creates innovative solutions for industry and research directly on real components.

Plant engineering that sets standards.

Start the conversation now

Would you like to find out more about the structure of the system, our technology platform or possible collaborations?

Then talk to us – we look forward to exchanging ideas.

Our systems in the moving picture