Content category.php

We had the opportunity to carry out an exciting modernization project for our customer, VEM Sachsenwerk GmbH. VEM is known worldwide for its high-quality medium- and high-voltage machines – from wind power generators to ship propulsion systems. Our goal was to bring the manufacturing technology for these components up to the latest state of the art.

![]() The challenge: Maximum performance in the smallest of spaces

The challenge: Maximum performance in the smallest of spaces

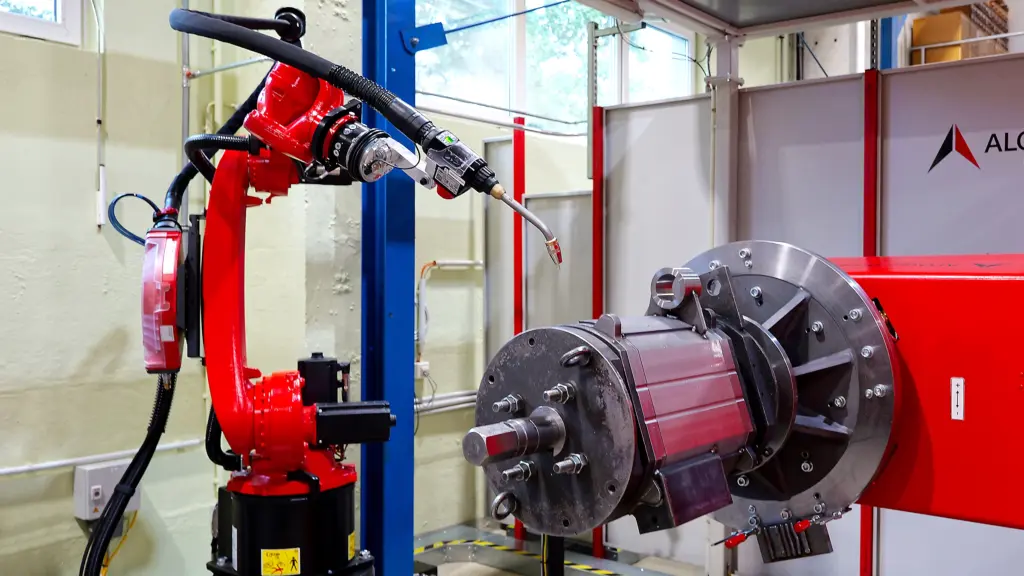

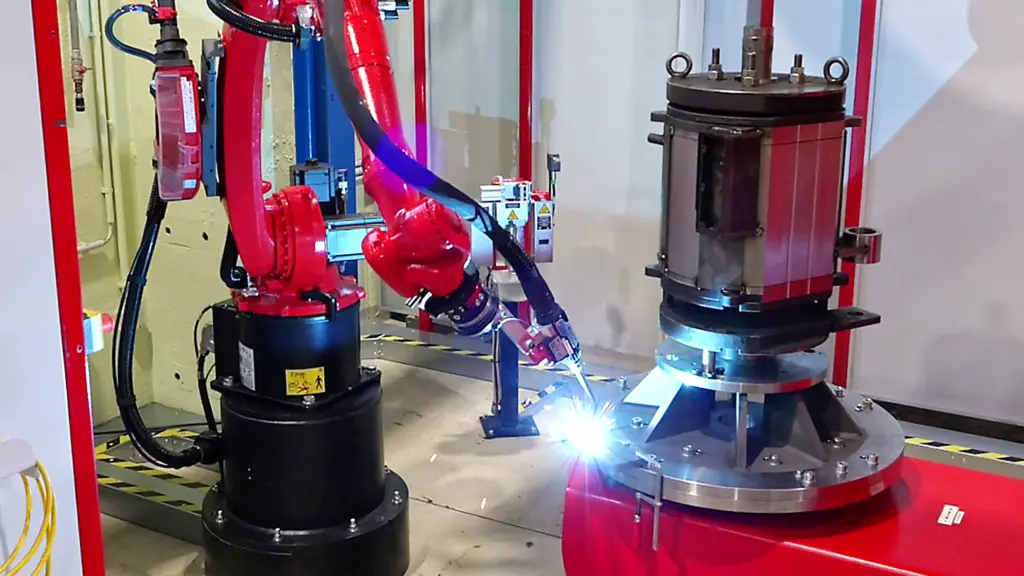

The task required a special engineering feat: the robotic welding system had to be as compact as possible, but at the same time be able to move heavy components safely. Our solution is a special design of the two-axis positioner (RDS-2600). By specifically shortening the swivel arm, we were able to minimize the space required without compromising on the maximum load capacity.

![]() Technology upgrade for arc welding

Technology upgrade for arc welding

At the heart of the new cell is a KUKA KR20 R1810 robot equipped with state-of-the-art welding technology. We integrated the Fronius TPS 400i system, which meets the highest standards for steel, stainless steel, and aluminum applications.

To make programming and handling in daily operation as efficient as possible, the system has been expanded with special software macros. These greatly simplify complex tasks such as rotationally symmetrical track repetitions or the welding of circular segments.

![]() An overview of the technical highlights:

An overview of the technical highlights:

- Robot: KUKA KR20 R1810 (6 axes, 20 kg payload)

- Welding technology: Fronius TPS 400i (wire/arc) including wire cleaning station and cutter

- Handling: Special design of the RDS-2600 positioner

- Components: Components for electric motors (connection welding)

We would like to thank VEM Sachsenwerk GmbH for their trust and successful cooperation on this project.

Would you like to learn more about our system engineering? We look forward to providing you with comprehensive advice.