Free Impulse Seminar

Laser hardening

Impulse Seminar Laser hardening

Experience laser hardening & WAAM systems live

Impulse seminar on September 24, 2025, in Dresden/Kesselsdorf

Experience the industrial application of modern laser processes in a compact afternoon seminar: In our free impulse seminar “Wear protection for metal components with laser hardening,” we will show you the technical, economic, and application-specific advantages of laser hardening and present current developments in the field of additive manufacturing.

This seminar is part of the “Additiv vor Ort” series organized by Building 3D e.V. and is supported by the Saxony Trade & Invest.

Register now for free – places are limited.

Laser hardening impulse seminar

Specialist presentations & technology insights

- Introduction to laser hardening

Dr. Steffen Bonß explains the process in comparison to conventional hardening technologies (e.g., furnace hardening, induction hardening, nitriding) and presents specific component applications. - Practical experience

ALOtec customers report on their experiences with the technology, focusing on cost-effectiveness, process stability, and component quality. - Technology insights with a focus on geometric diversity

Dr. Clemens Kuhn presents special optics for hardening complex components and applications in the field of laser cladding.

Hands-on plant engineering

Collaborative WAAM system under construction

During the event, we will be presenting our new WAAM (Wire Arc Additive Manufacturing) system for the first time, which is currently being developed for BTU Cottbus.

- Two collaborating robots in master-slave mode

- 16 synchronized axes for high flexibility

- Powerful WAAM processes based on the latest Fronius technology

The facility represents the real-world implementation of industrial additive manufacturing technology – right on site and open to visitors.

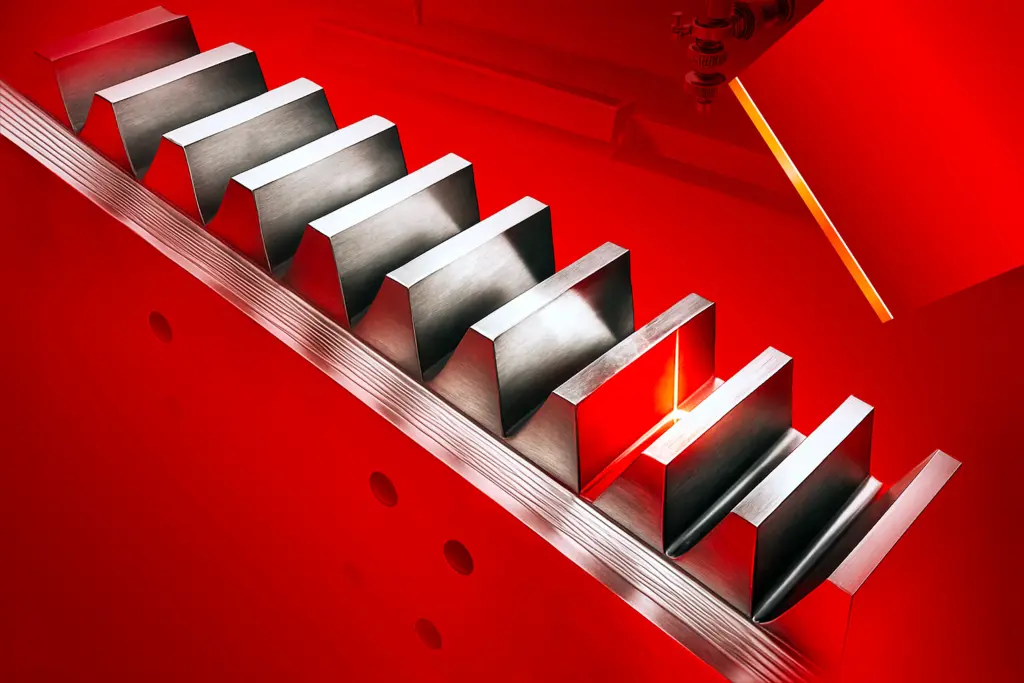

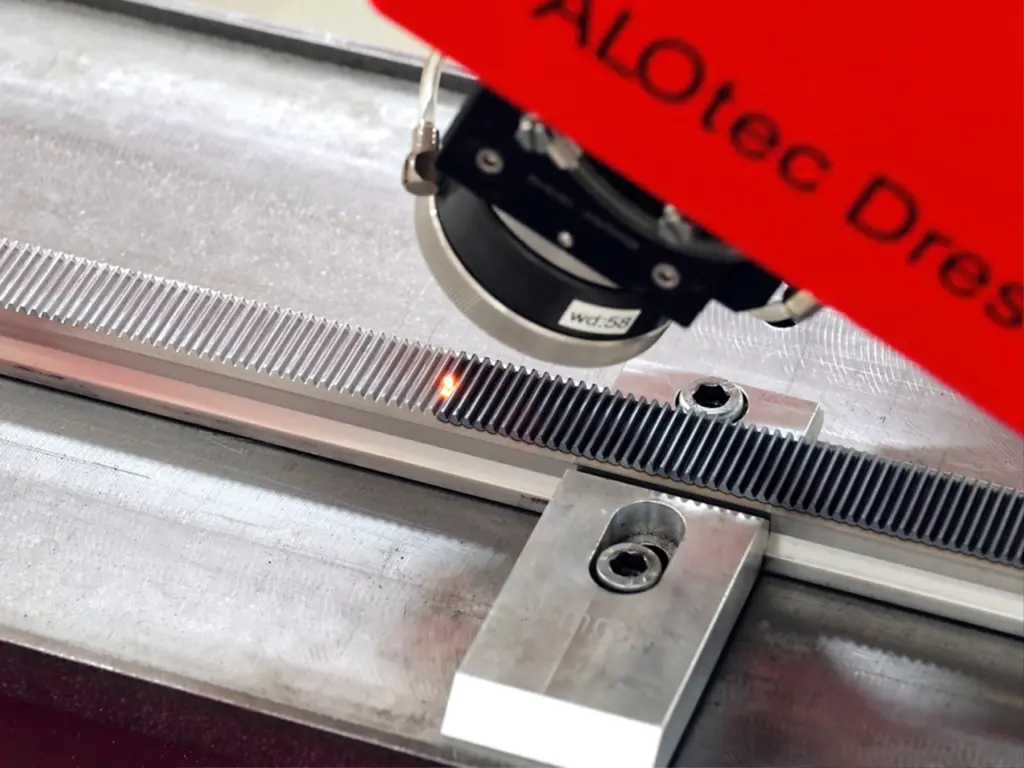

Wear protection through laser hardening

Live demonstration

At one of our facilities, we will demonstrate laser hardening in real-life operation. Experience the entire process live—from programming to the various optics to the hardened component.

Space for exchange

Professional exchange & conclusion

Coffee, cold drinks, and light snacks will be available throughout the event.

At the end of the event, we invite you to join us for a relaxed get-together at the buffet – ideal for in-depth discussions, professional exchanges, and personal networking.

Laser hardening impulse seminar

Event details

Venue

ALOtec Dresden GmbH

Zum Wiesengrund 2

01723 Kesselsdorf

Date and time

Wednesday, September 24, 2025

1:30 p.m. to approx. 4:00 p.m.

Target group

The seminar is aimed at specialists and managers from the following industries:

- Mechanical engineering

- Metal processing

- Mold and gear manufacturing

- Automotive

- Agricultural engineering

- Mining

Registration

Register now for free via Building 3D.

Participation is free of charge. Due to space limitations, the number of participants is limited.

What others think about the technology

Laser hardening from the customer’s perspective

“We have actively opted for laser hardening in selected projects because we are very satisfied with the performance and would like to pass on the advantages of laser hardening to our customers!”

Laura Erbert, Project management Getriebebau Nossen