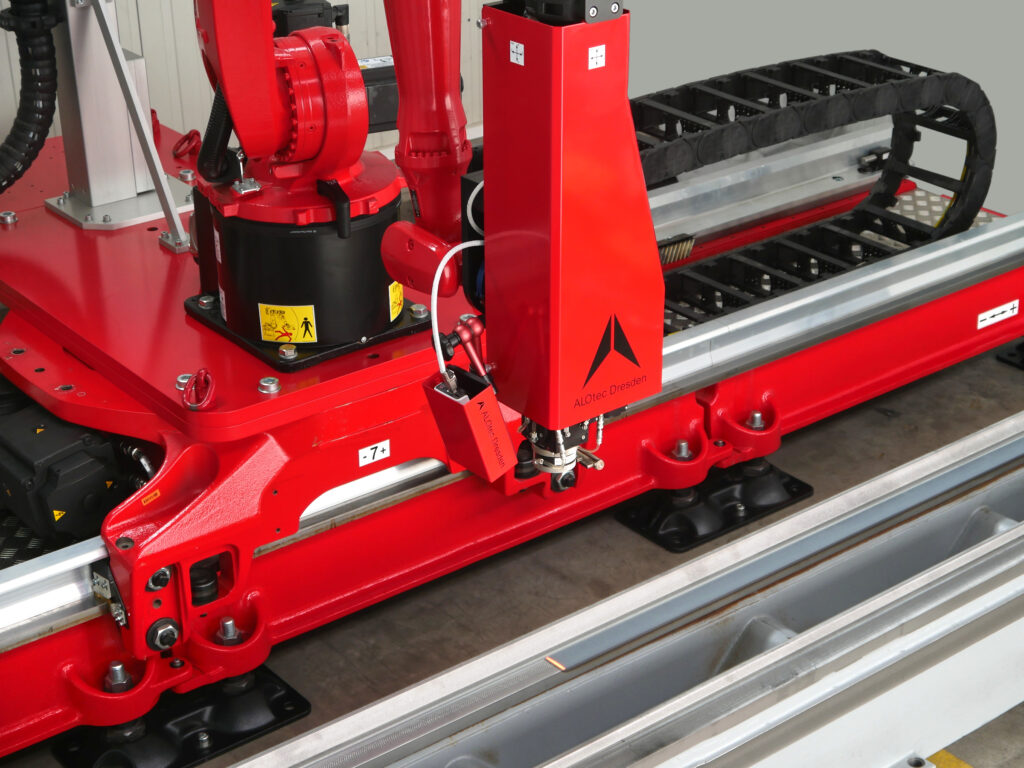

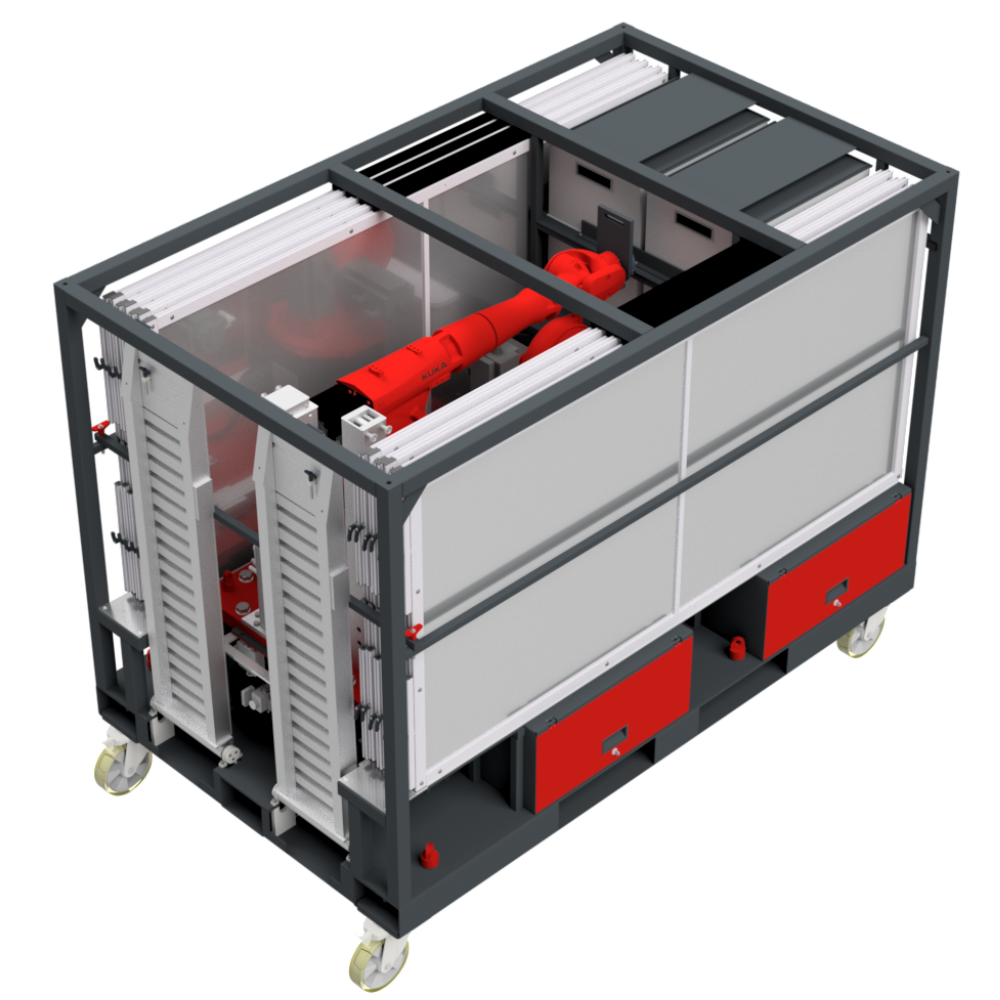

The components of the laser system are compactly stowed away for easy transportation.

Precise and mobile

ALOhybrid

ALOhybrid

Hybrid laser systems

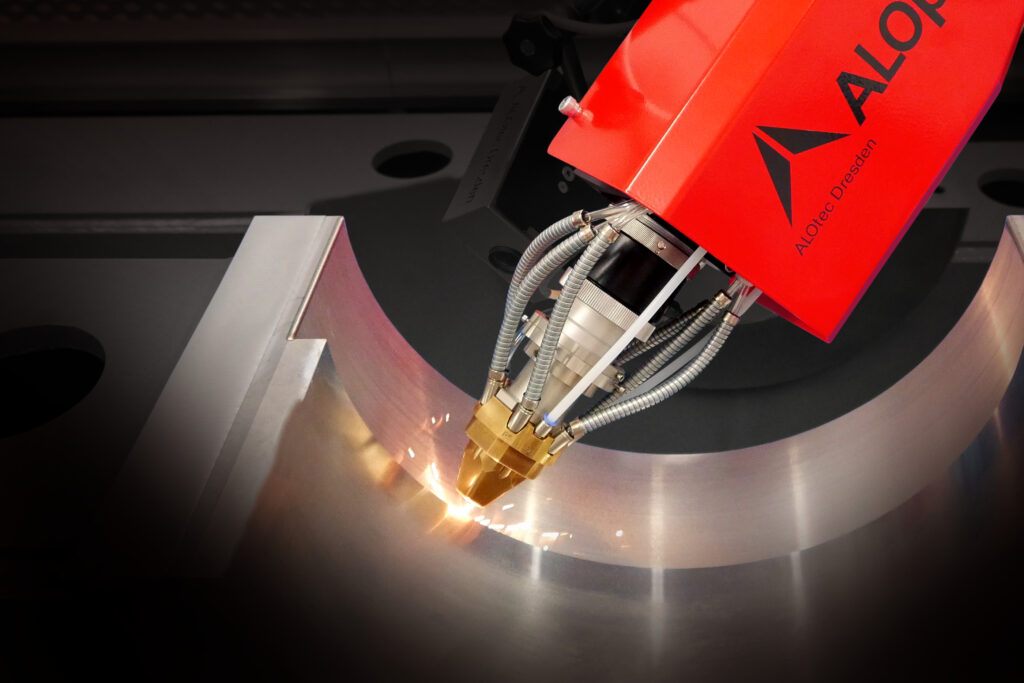

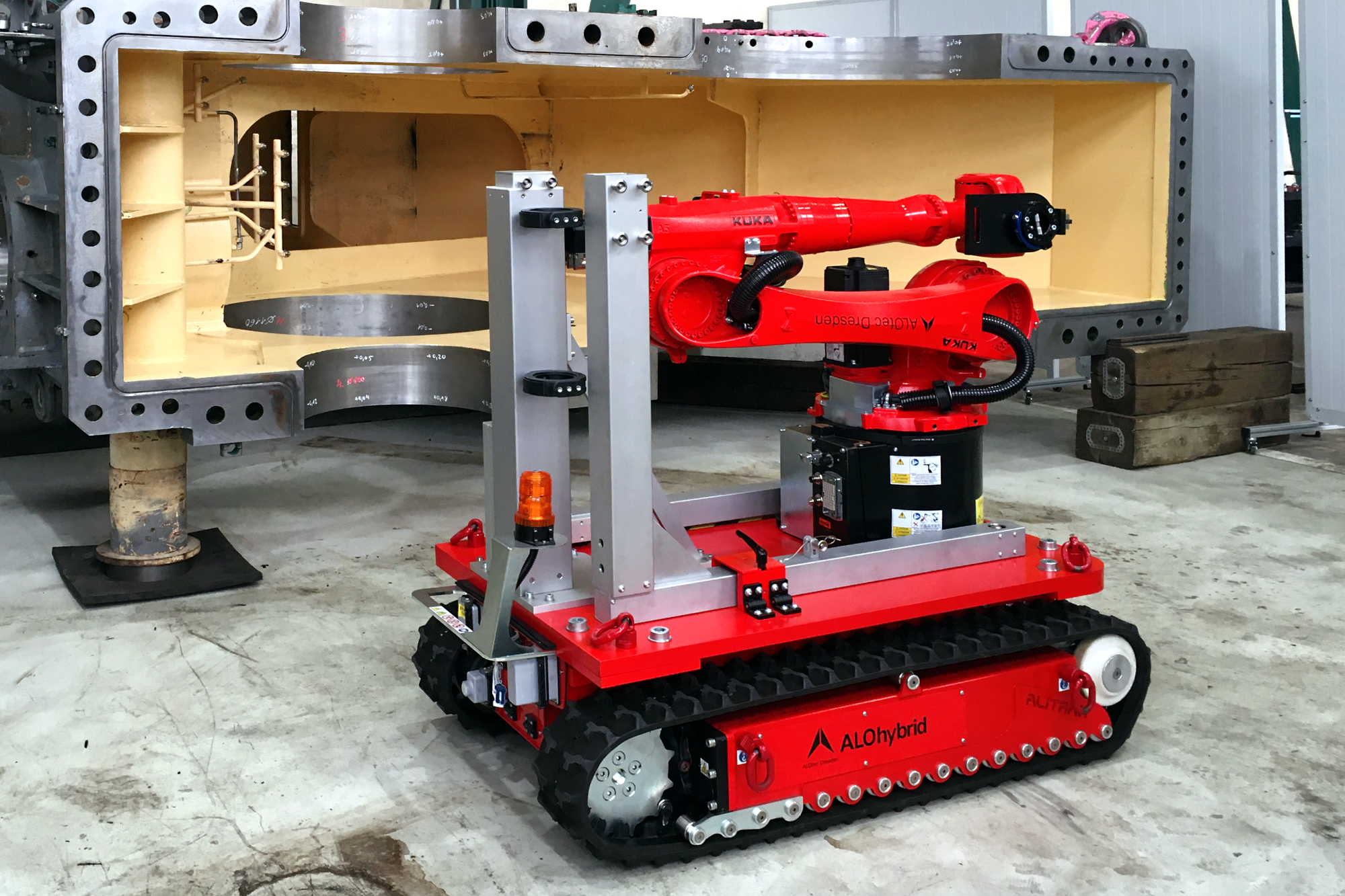

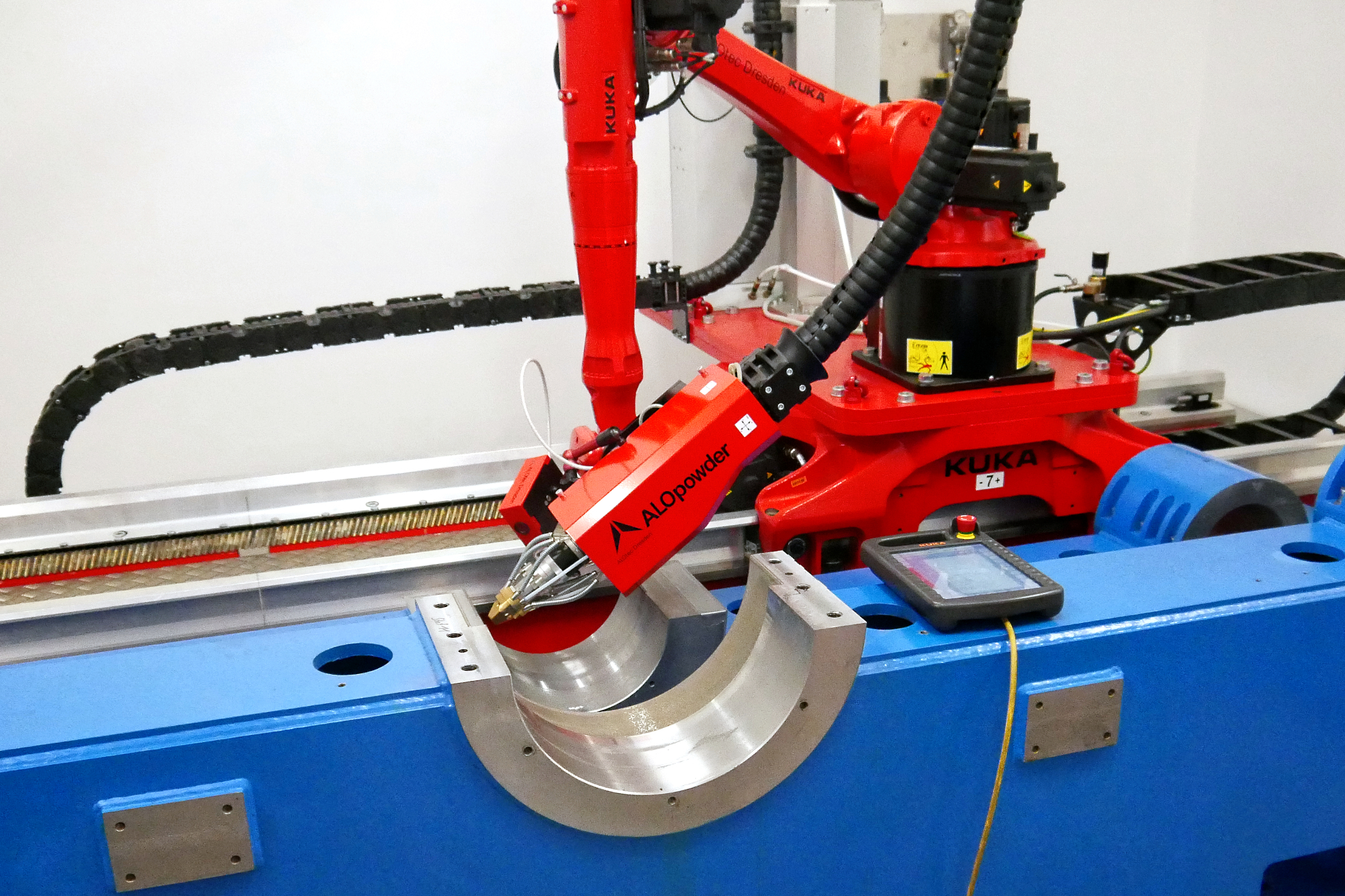

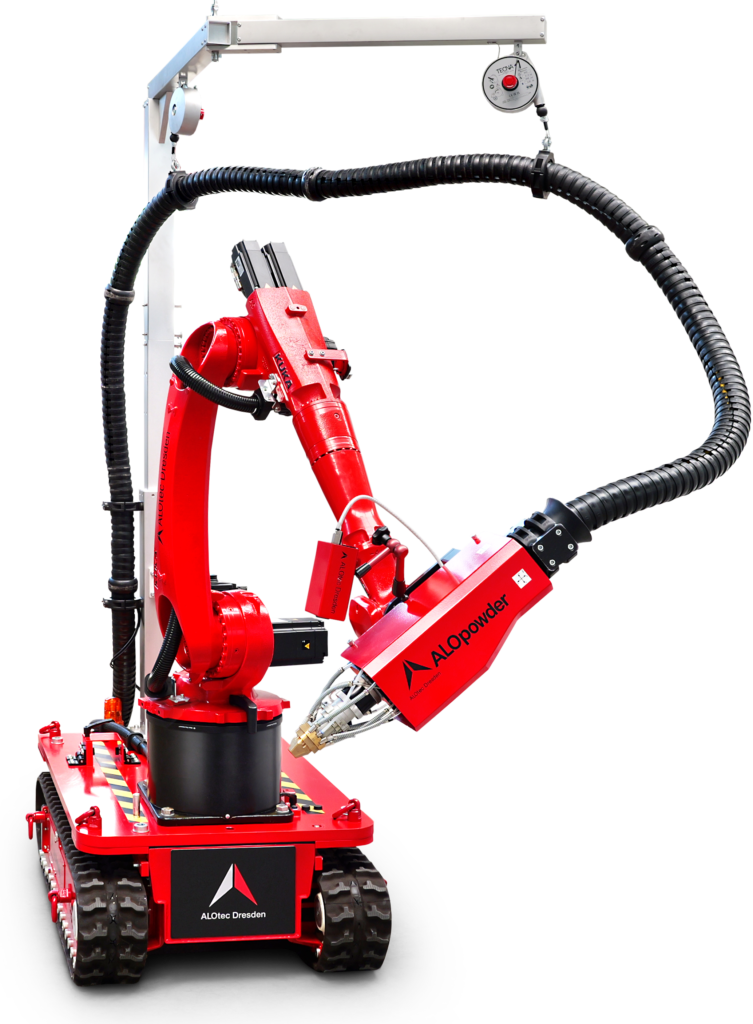

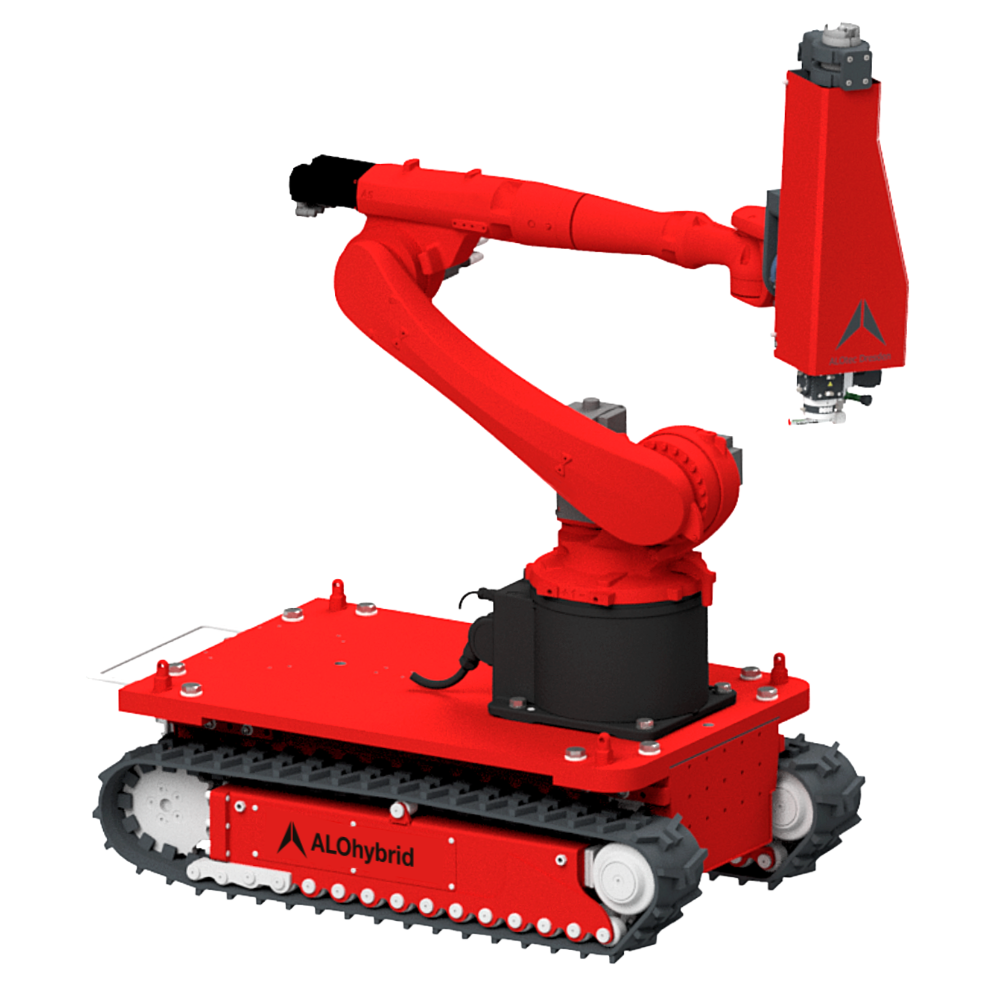

ALOhybrid is the world’s first hybrid 10-axis system for laser processing – a perfect combination of a stationary and mobile laser system.

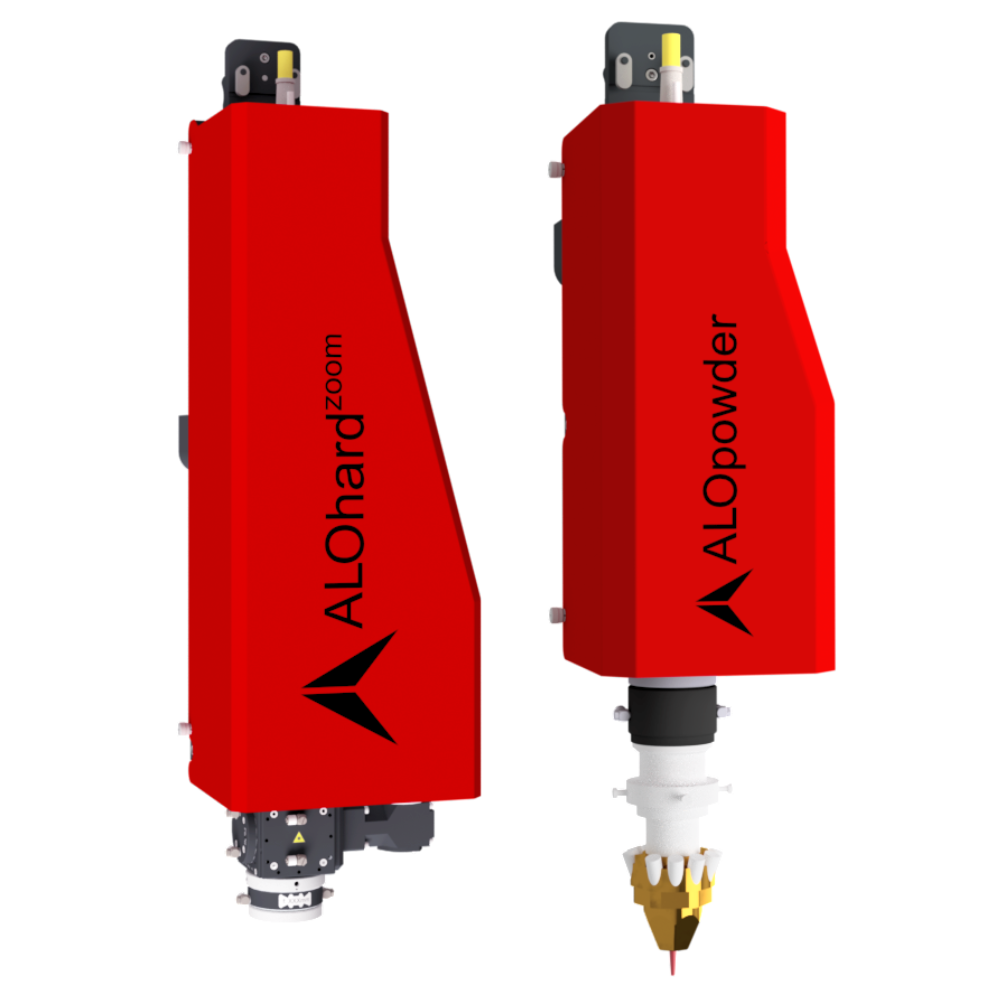

The ALOhybrid is characterised by precision and flexibility – the best of both worlds. The system can be equipped with ALOhard laser hardening optics, ALOpowder laser cladding optics and ALOarc arc welding. The system can be customised with additional components from the modular equipment.

Precision and mobility

The ALOhybrid concept

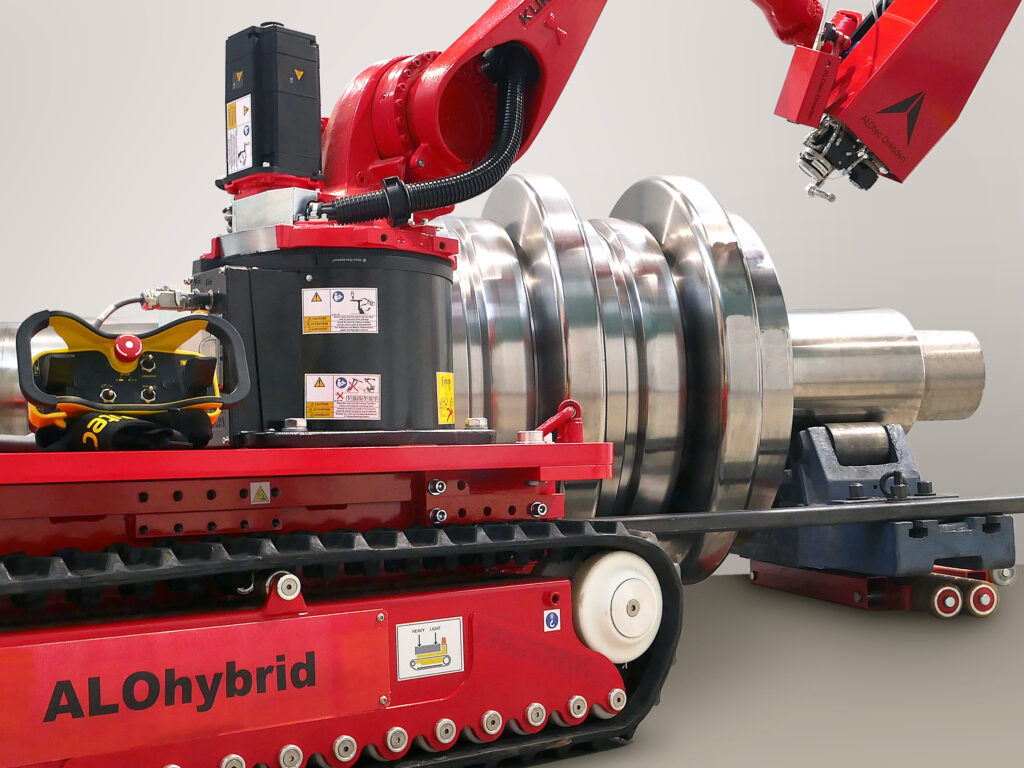

With the ALOhybrid laser system, you get the precision of a stationary system and the flexibility of a mobile laser processing system. The system is suitable for processing forming tools, machine parts, cutting tools or screw conveyors, rollers and shafts and much more.

In mobile use, the robot is connected to the media station via a 15 metre long, flexible energy chain and has a large, mobile working radius.

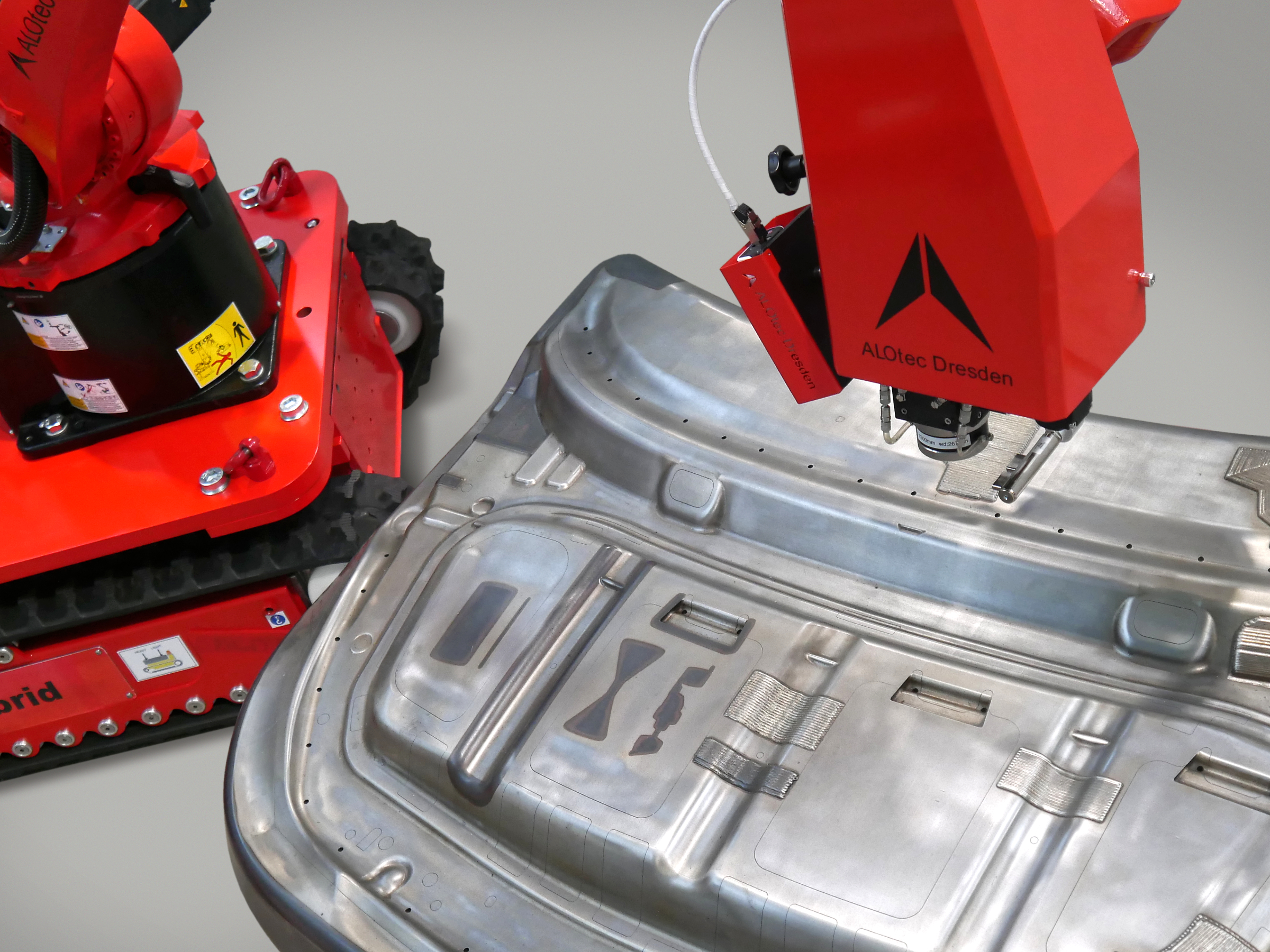

The ALOhybrid is designed for alternating use as a stationary system on a linear unit and as a mobile system on a crawler or directly on the component to be machined using a multi-clamping plate.

ALOhybrid – mobile and stationary use!

Hybrid laser system ALOhybrid

Flexible and precise

As well as being suitable for use as a stationary or mobile system, the ALOhybrid impresses with a fast and smooth technology change using a quickcoupling system, 10 synchronised axes and user-friendly operation and control.

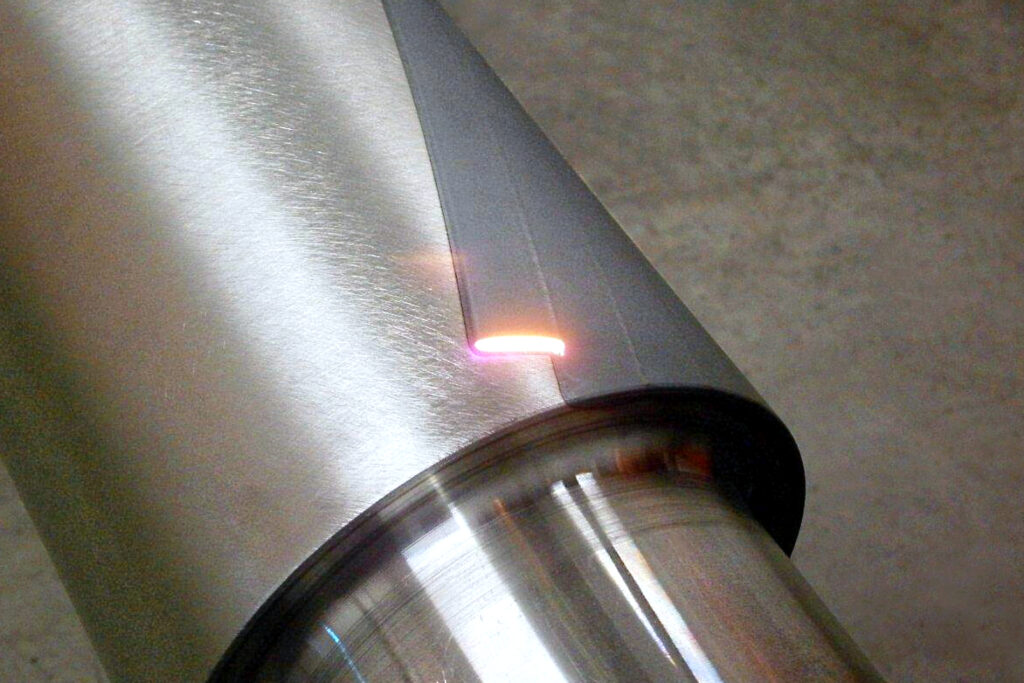

Mobile use Laser hardening with zoom

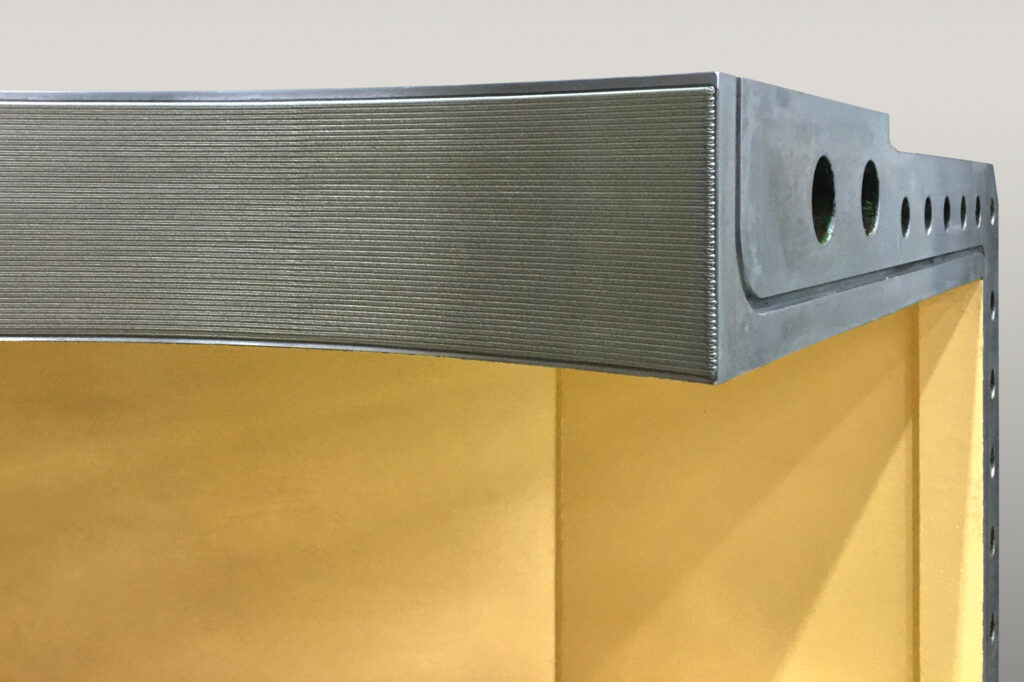

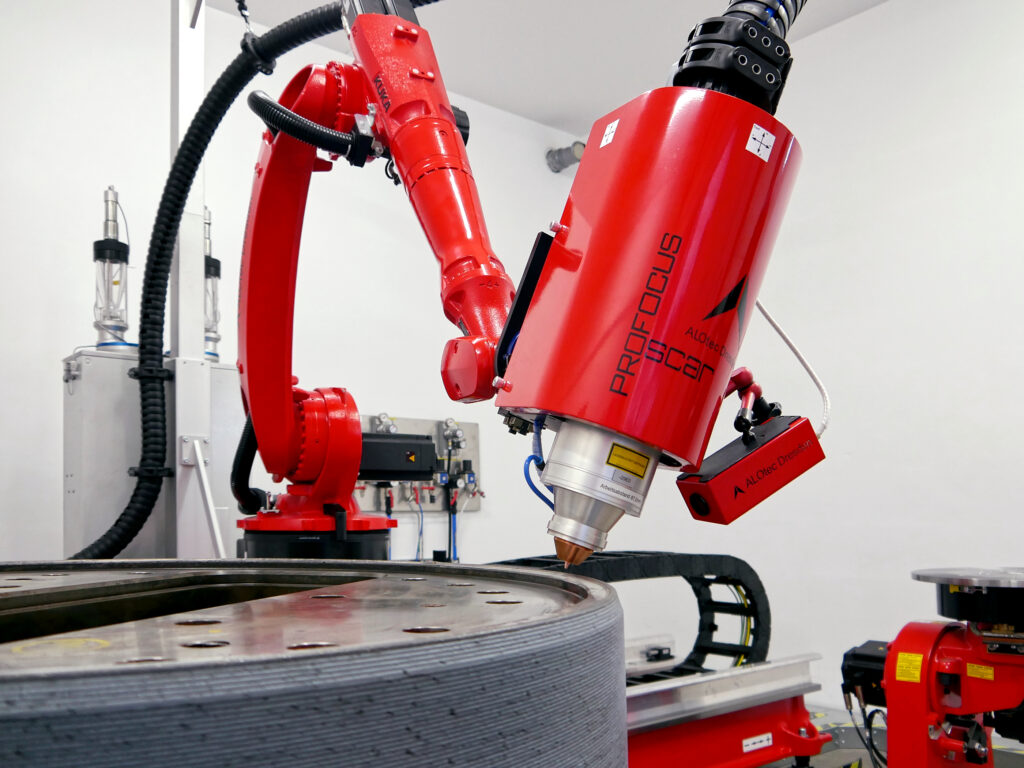

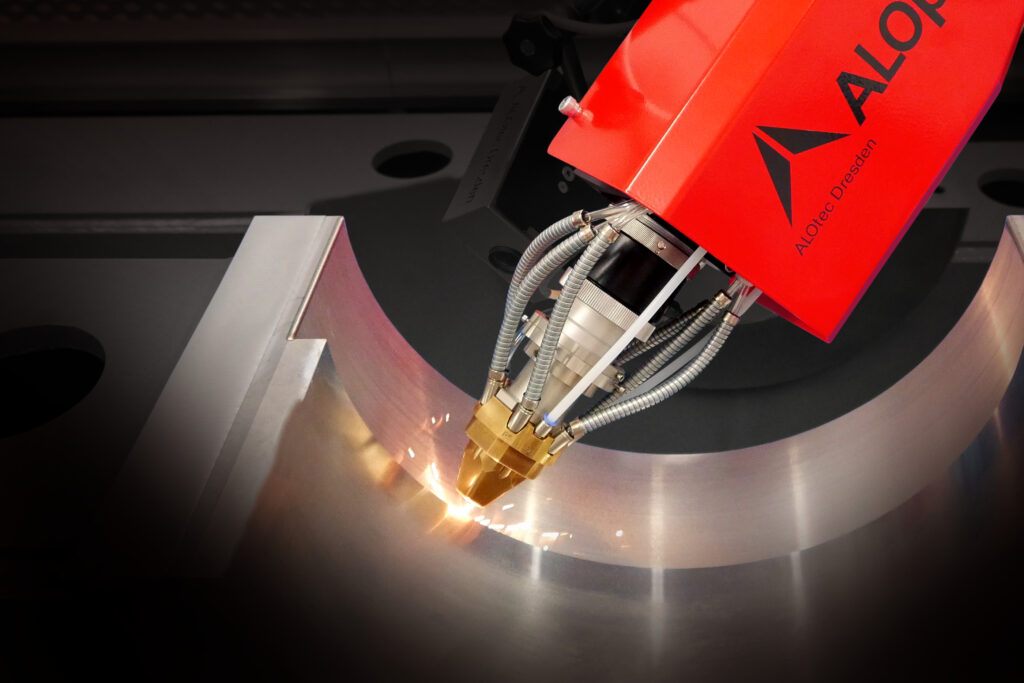

Stationary use Laser cladding

Technology change with quickcoupling system

Technology in hybrid operation

Wide range of applications

![]() ALOhard and ALOhardzoom laser hardening, ALOpowder laser powder cladding and ALOarc CMT welding in mould and tool making and mechanical engineering

ALOhard and ALOhardzoom laser hardening, ALOpowder laser powder cladding and ALOarc CMT welding in mould and tool making and mechanical engineering

![]() Specific hardening of metallic surfaces and repair or reconditioning of highly stressed component surfaces

Specific hardening of metallic surfaces and repair or reconditioning of highly stressed component surfaces

![]() Suitable for processing forming tools, machine parts, cutting tools or screw conveyors, bearing seats, rollers and much more

Suitable for processing forming tools, machine parts, cutting tools or screw conveyors, bearing seats, rollers and much more

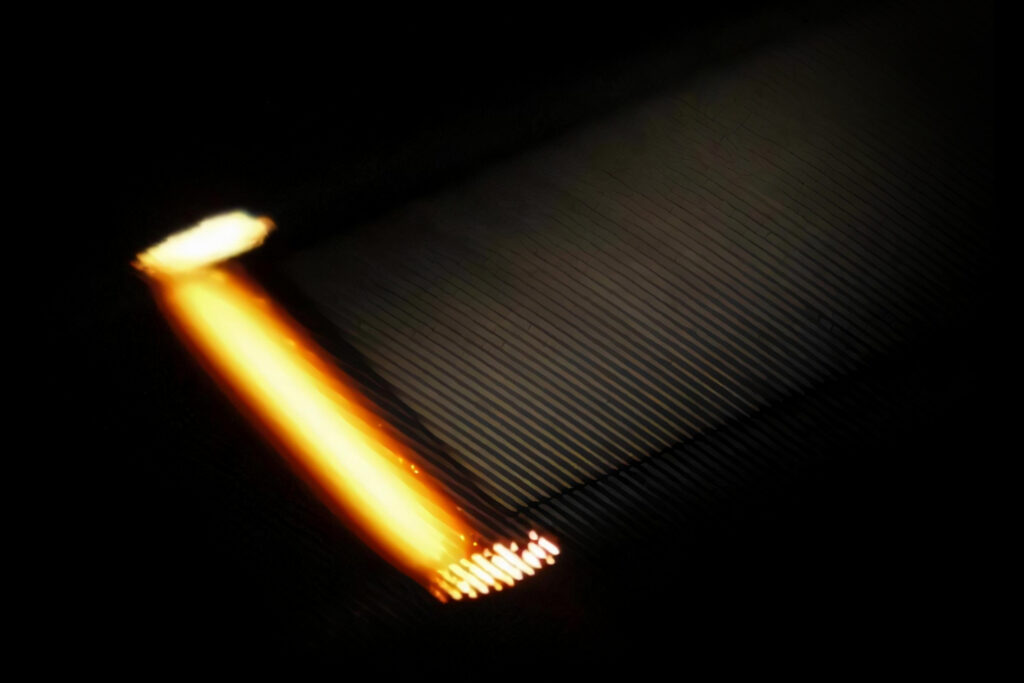

Laser hardening

with fixed and variable laser track widths

Arc welding

CMT welding with ALOarc

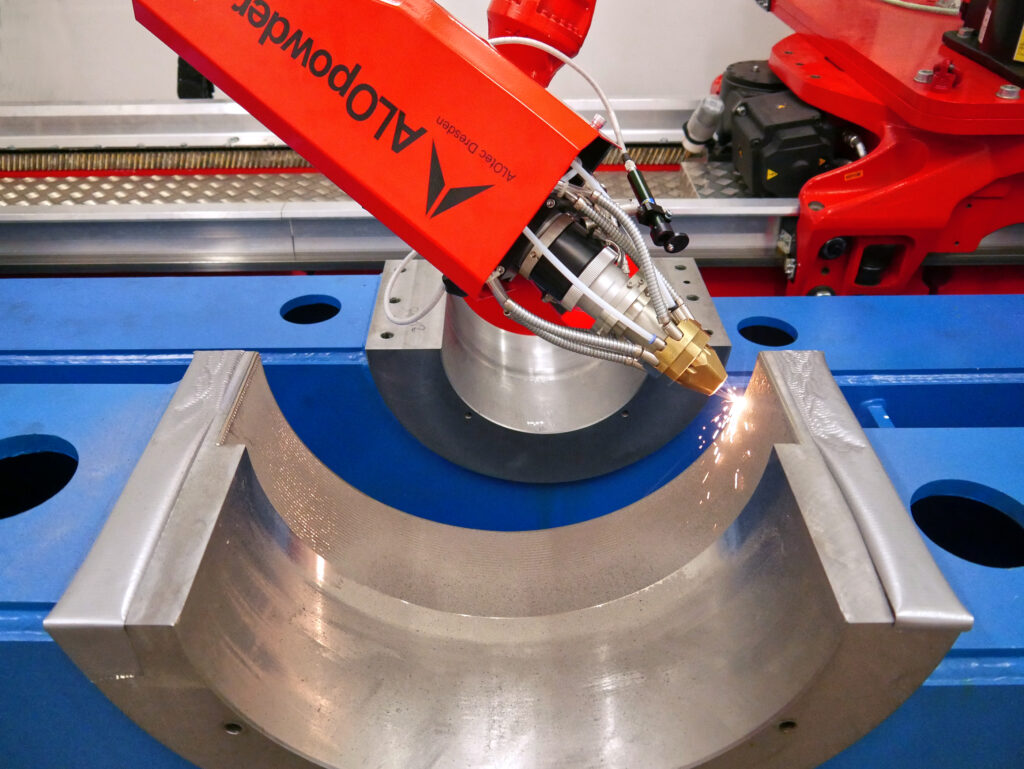

Cladding

with powder

Additional applications can be optionally employed: laser powder cladding with interior cladding optics* ALOpowderID, laser wire cladding* ALOwire, hardening with dynamic scanning optics* ALOhardscan, and a hybrid technology combining wire and powder cladding* ALOtwin.

*For these applications, modules of the hybrid laser system need to be adjusted.

On site at the customer component

Mobile processing

-

Transporting the mobile laser system

-

Loading the mobile laser system

The components of the laser system are located in transport-optimized stations and are therefore quick to load and easy to transport.

-

Setting up the mobile laser system

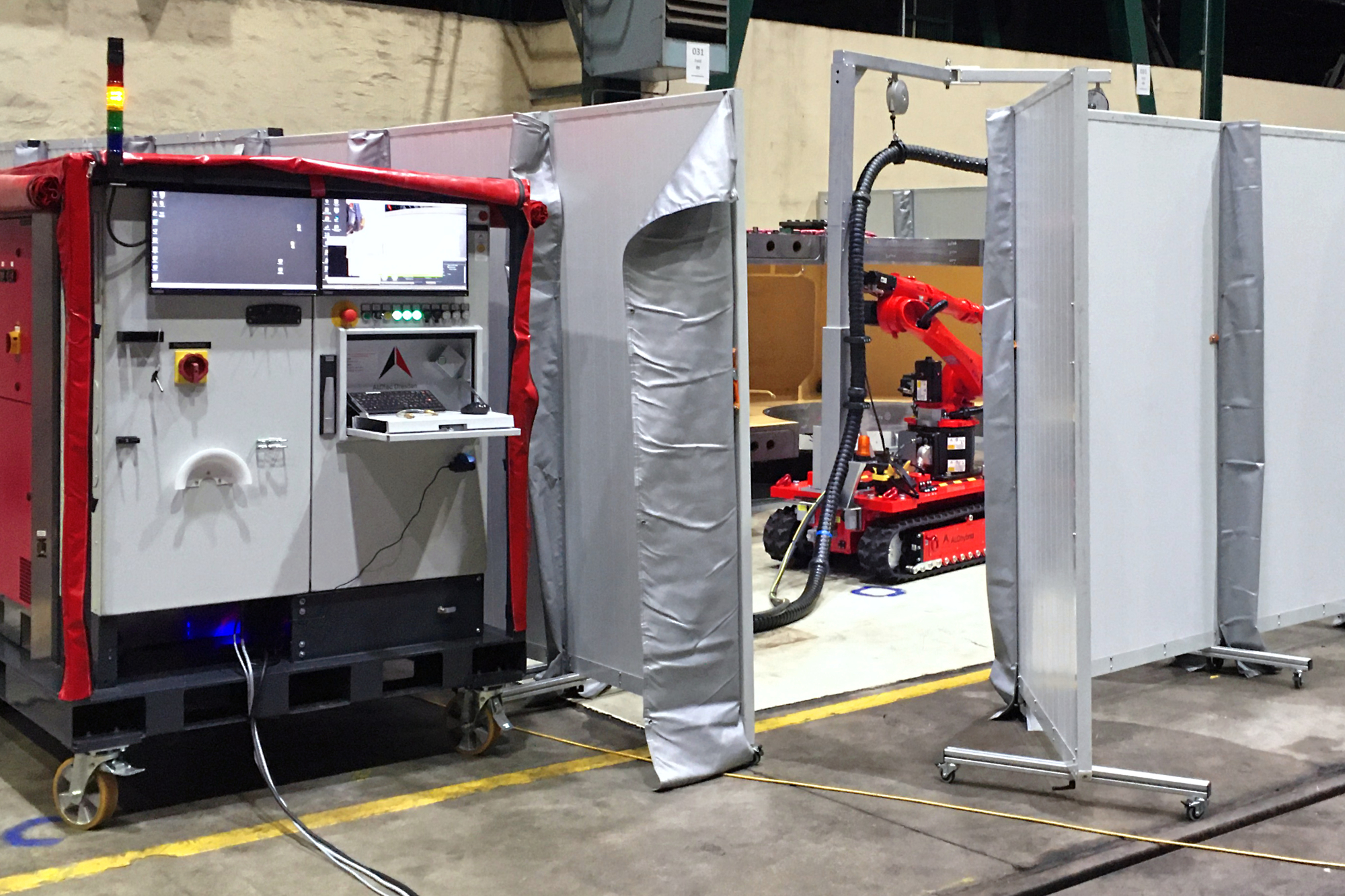

The mobile laser system is positioned and set up on site on the component.

-

Teaching the mobile laser system

Simple creation of the welding paths on the component by teaching the mobile laser system.

-

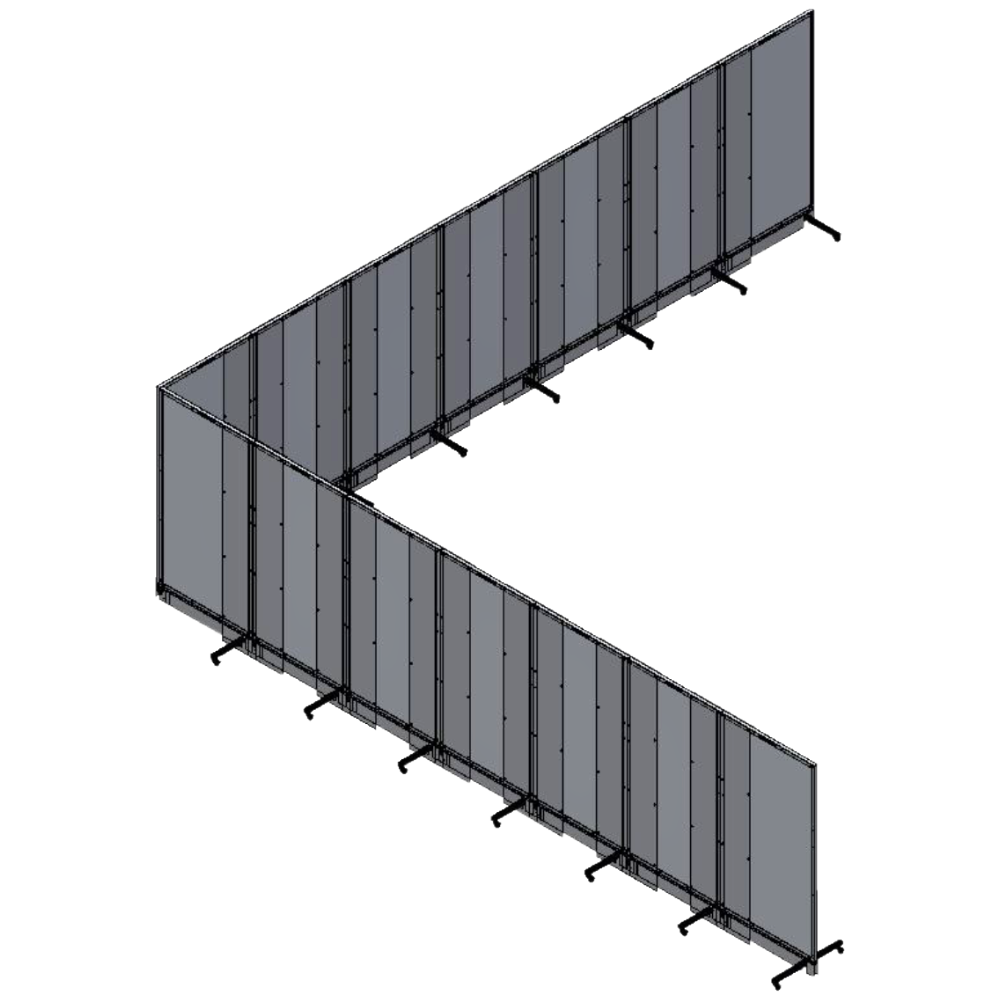

Setting up the laser safety barriers

Setting up the certified laser safety barriers around the component with the mobile laser system.

-

Setting up process control

Setting up system monitoring and process control, laser power measurement and documentation of process parameters using OPC UA.

-

Fully set up mobile laser system

The system and the powder feeder are positioned in front of the component and fully set up.

-

Process recording

Recording of the process camera during laser powder cladding on the component.

-

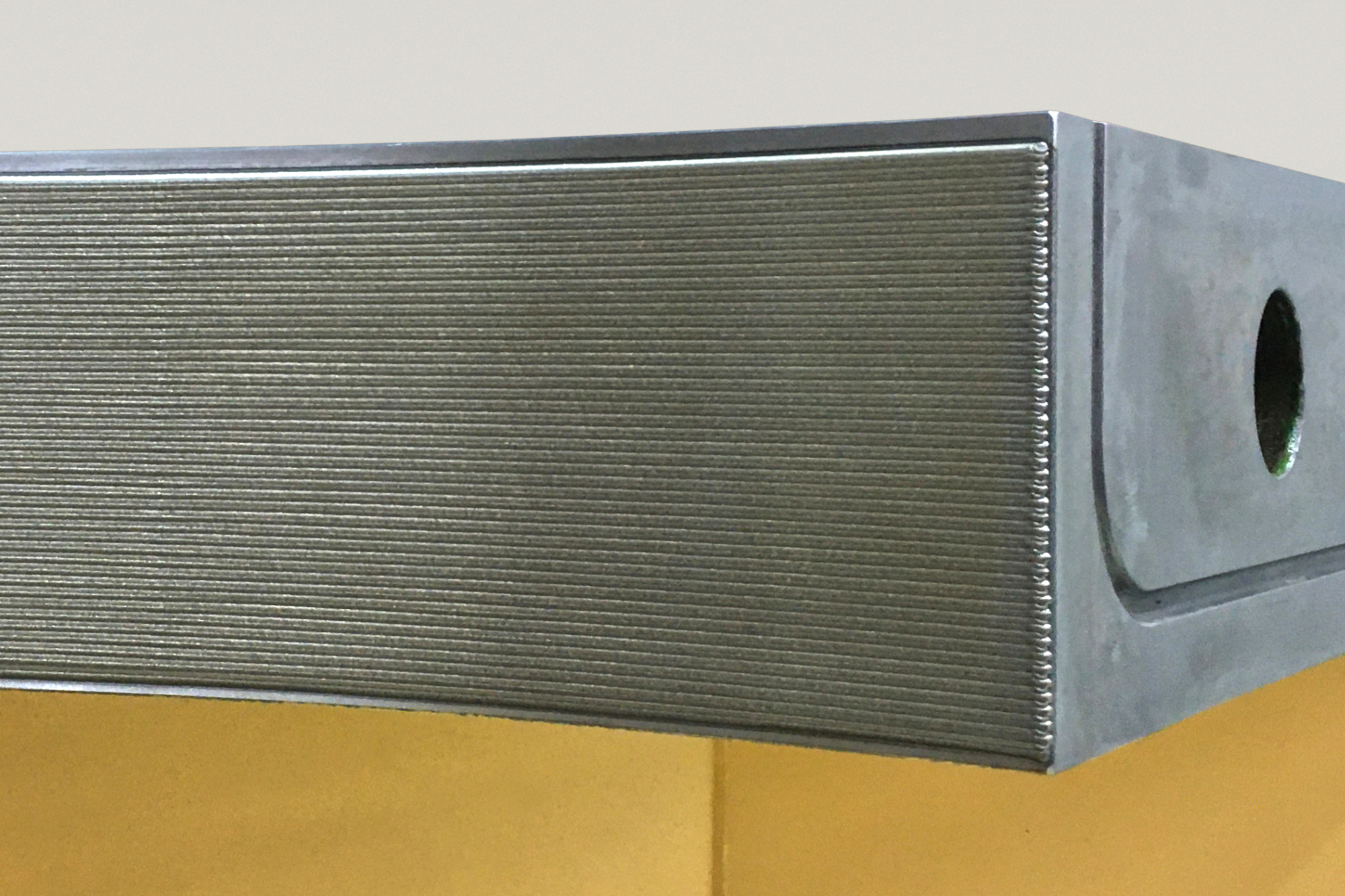

Finished bearing seat

Welding pattern as a meander track on a bearing seat with a track width of 3.8 and a layer height of 1.0 mm

-

Use as a stationary system

After the mobile repair work on site on the component, the laser system continues to be operated as a stationary 10-axis laser system.

Hybrid laser processing

Advantages of ALOhybrid

Precision and flexibility

Use on crawler tracks, on components or as a stationary support

Up to 10 synchronised axes

Up to 8 for mobile use and up to 10 synchronised axes for stationary use

Fast technology changeover

with the ALOtec quick-change system

Continuous documentation

of process parameters and laser power

Simple system positioning

on the component with the help of the crawler

Maximum 10 kW laser power

Up to 10 kW laser power possible

Simple system operation

Simple operation thanks to predefined programme sequences

Offline programming

via CAD/CAM and scan of the geometry for path planning

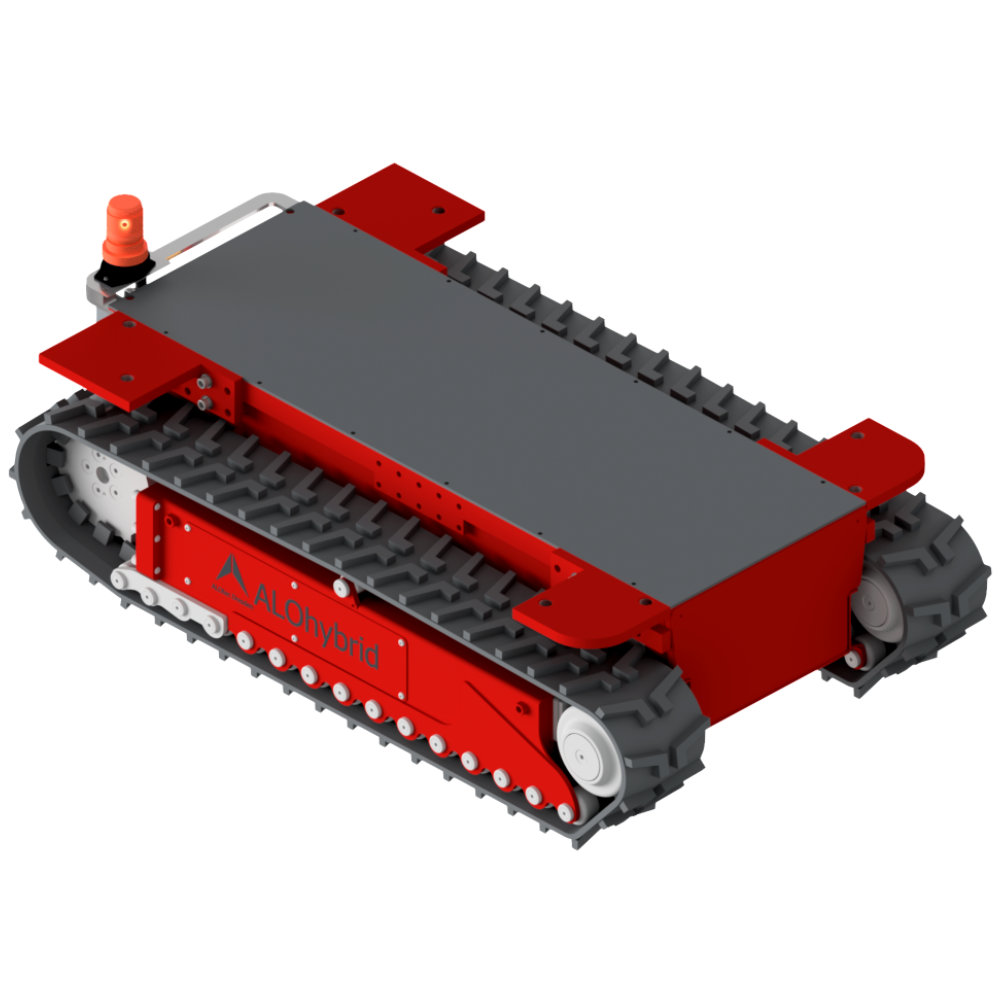

Sophisticated transport concept

Optimised transport dimensions for trucks, ships or planes

Modular system

Technical equipment

We design and manufacture your customised, mobile and stationary laser system for hardening, cladding with powder and wire or CMT welding.

Connections

Electricity / Compressed air / Gas

Robot

Axes / Reach / Payload

Laser

Power

Optics

Hardening / Cladding / CMT welding

Peripherals

Positioner and linear unit

Add ‑ on

Auxiliary and additional devices

Software

Auxiliary and additional devices

Customised equipment

System modules

Processing optics for laser hardening and cladding

6-axis robot for 3D laser beam movement

Linear unit for stationary use

Crawler unit with remote control for mobile use

Turn/tilt table with 1 or 2 axes for positioning

Mobile media station for mobile systems

Mobile station for safety barriers and robot

Laser safety barriers with certified laser protection concept

Want the best of both worlds?

Here it is:

The ALOhybrid hybrid laser system is designed for a wide range of applications and is modularly expandable. It is easy to operate and pre-installed programme sequences guide you quickly and safely through the processes.

Our laser systems in the moving picture