Container based system

ALOcase

Repair Station for Deployment

Mobile Metal 3D Printing

On-site repair and additive manufacturing – fast and easy.

Discover our mobile, container-based laser system for repair and additive manufacturing using laser cladding and arc welding.

Save time and money by having your armed forces repair or rebuild defective components directly on site. Quickly ready for use in the container or outside in the field thanks to the intuitively controllable crawler – our mobile, robust laser system is ready for efficient and high-quality repair solutions.

Our mobile laser system gives you maximum flexibility for rapid reuse of your military equipment!

Robust. Versatile. Fast.

Our Solution

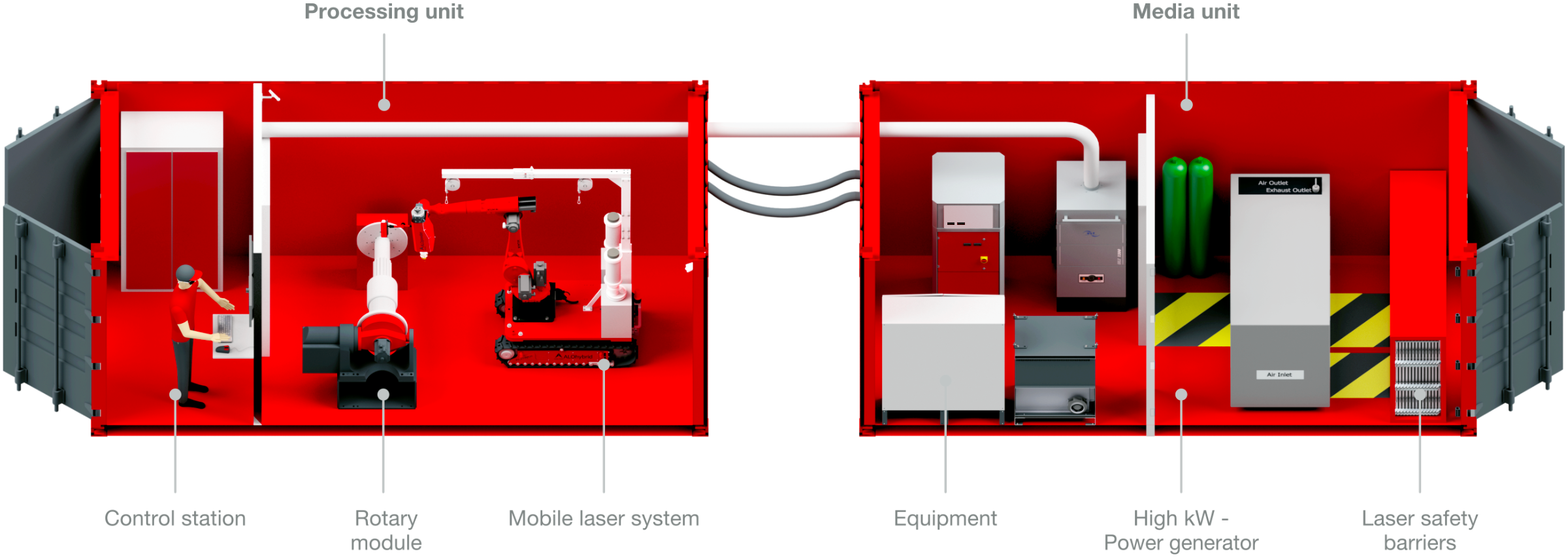

Mobile 3D metal printing center in two fully integrated 20-foot container-based systems. The system consists of a laser processing station for metal 3D print and repair jobs and a workstation area including a self-sufficient power generation of 32 A connection.

![]() Mobile Metal 3D Print

Mobile Metal 3D Print

- Robot system for direct energy deposition

- Metal 3D printing and repair jobs

- High deposition rate with various materials

- Simple contour measurement and programming

- No CAD file needed

- Operational inside and outside of the container

![]() Arc welding

Arc welding

- Specially suited for high deposition rates

- For cladding and welding

![]() Laser powder cladding

Laser powder cladding

- Application of wear-resistant coatings on components

- Precise modification of component geometries

![]() Specifications

Specifications

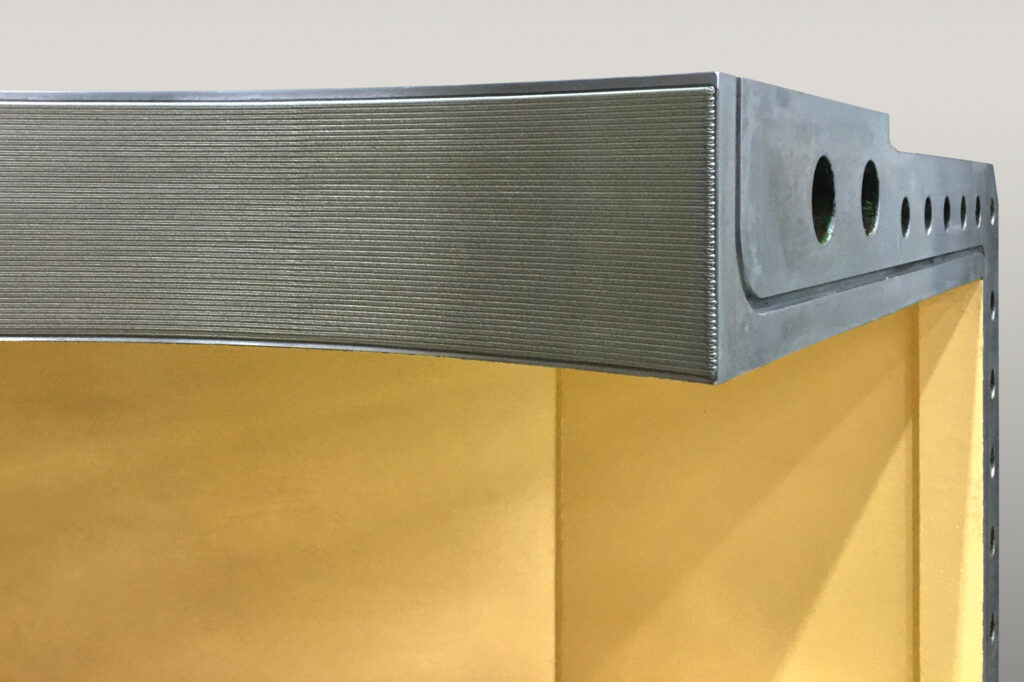

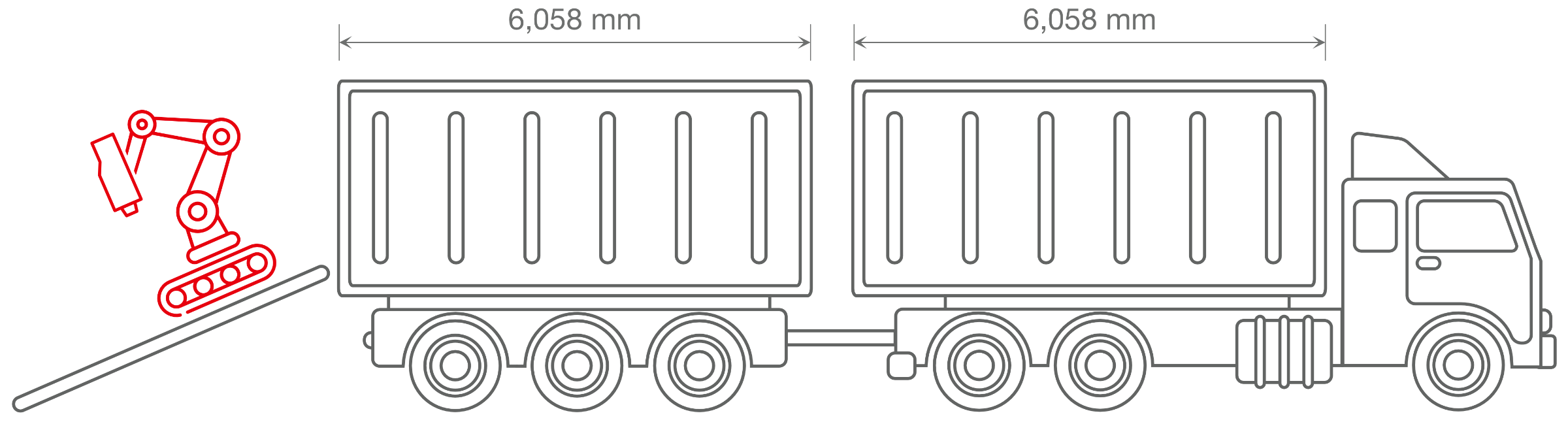

- 2 x 20 ft containers „High Cube“ for efficient transport

- Self-sufficient for several days thanks to power generator

- Easy to set-up

- System can work up to 15 meters outside the container

- Configuration according to your needs

Fast and efficient on site.

Container based system

The two fully integrated containers consist of the standard “High Cube” container system and can be transported quickly and efficiently to the repair site. The containers have a length of 6058 mm, a width of 2438 mm and are 2896 mm high.

The robot system can be driven out of the container via an access ramp and positioned directly on the appliance to be repaired. The system can be used up to 15 meters outside the container.

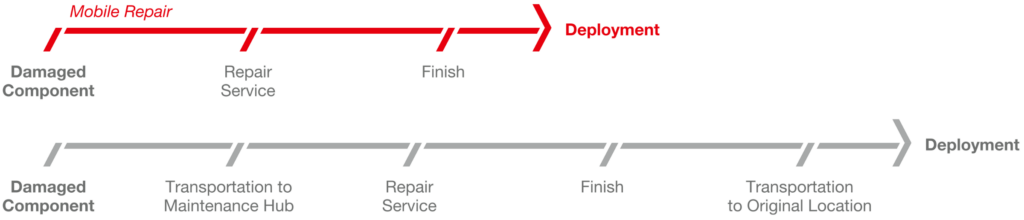

Reduces transportation times and increases combat readiness by up to 50 %!

On site – fast and easy

Your Advantages

Time-Efficient

Time saving compared to new procurement

or stationary repair and ready for use in

less than 20 min.

On-Site Deployment

Directly on site thanks to optimized transport containers. Can be used inside and up to 15 meters outside the container.

Simple operation

Robust laser system with simple and precise operation by just one user for efficient and high-quality repair solutions.

Advanced Technology

Laser powder cladding for repair and wear protection coatings and modifications of component geometries. Arc welding for cladding and welding.

Solutions you can rely on

Features

We offer a wide range of applications for efficient and high-quality repair solutions. Our mobile laser system gives you maximum flexibility for rapid reuse of your military equipment!

Technology

![]() Laser powder cladding: Application of wear-resistant coatings on components and precise modification of component geometries

Laser powder cladding: Application of wear-resistant coatings on components and precise modification of component geometries

![]() Arc welding: Specially suited for high deposition rates and for cladding and welding

Arc welding: Specially suited for high deposition rates and for cladding and welding

Cladding

with powder

WAAM

Wire Arc Additive Manufacturing / CMT welding

System

![]() Mobile 3D metal printing center in two fully integrated 20-foot container-based systems.

Mobile 3D metal printing center in two fully integrated 20-foot container-based systems.

Processing unit

Media unit

Our container-based system in the moving picture

Roll it – Laser on

Are you interested?

Let´s talk!

Are you interested in our container-based system, do you need advice or would you like to receive a quote?

Please use the form below for a quick response.

Compact and flexible like no other!

We can do mobile.

The ALOflex mobile laser system is designed for a wide range of applications directly on the component at the customer’s site and can be expanded on a modular basis.

Our laser systems in the moving picture