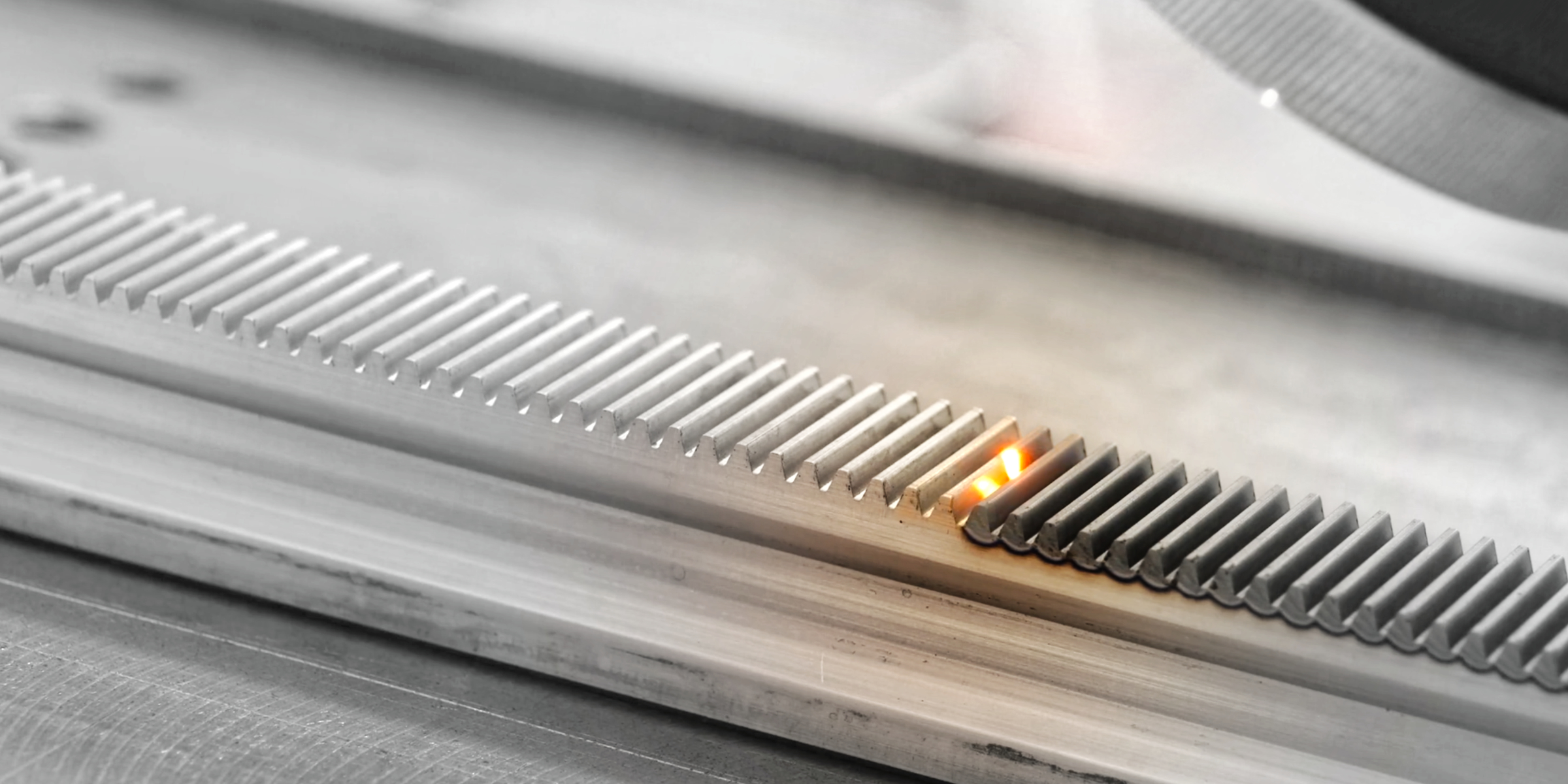

Laser hardening of gear racks with ALOhardzoom

The precise laser hardening of the tooth flanks ensures high gear quality and a long service life. Due to the defined heat input through the laser spot the smallest possible distortion of the part is achieved.

Using ALOhardzoom we are able to react to different tooth geometries (modul, area to be hardened etc.) – the laser hardening process is ideal for complex components due to the precise control and flexible shaping of the laser beam.

Our laser power control permanently monitors the hardening process via a thermal camera and regulates the laser power depending on the temperature, keeping it constant to ensure a homogeneous hardening result.

Our new video about laser hardening of gear racks on Youtube:

ALOtec Dresden delivers a robust laser hardening process and convinces with speed and reliability.