Why laser hardening? A practical example from the industry

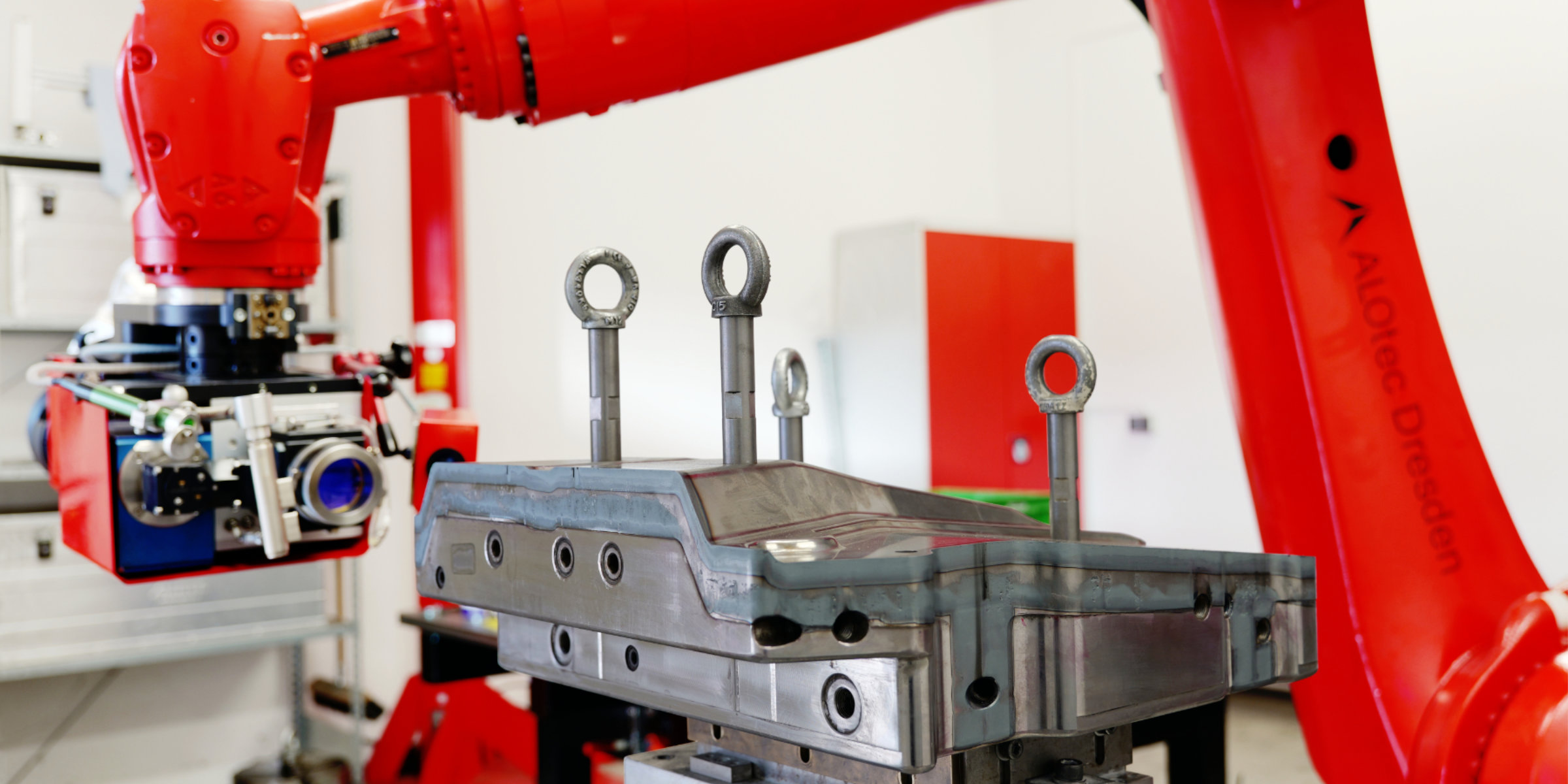

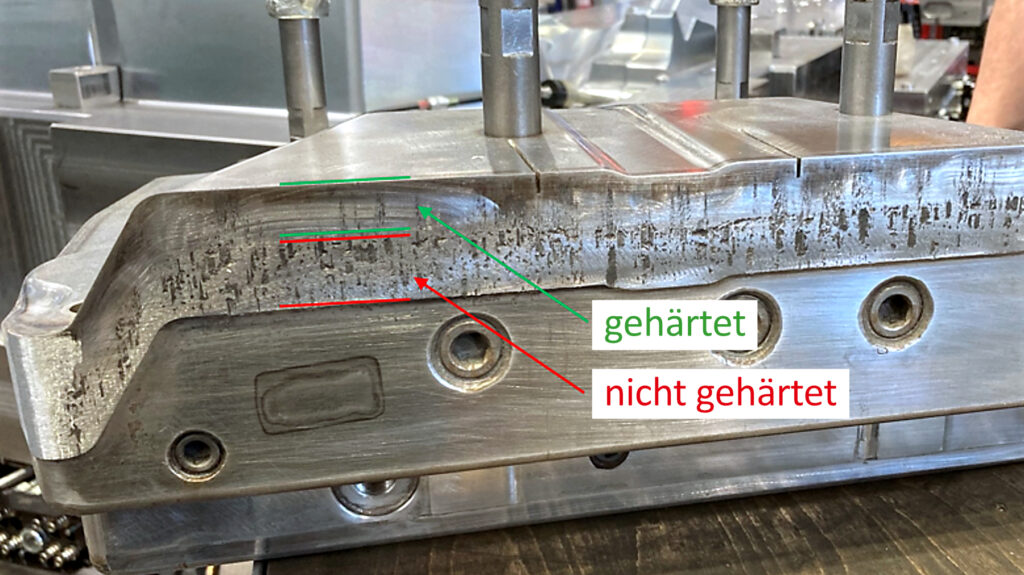

Laser hardening at ALOtec: a stroke segment component was already hardened by us in 2021 and has been in use in the industry for a full 3 years since then. The results speak for themselves: in the hardened area that we treated back then, wear has remained almost minimal. The areas that were not hardened, on the other hand, show clearly visible scuff marks – typical signs of wear that can occur on unprotected surfaces..

Now, after three years, our customer has turned to us again. The task: to also harden the previously untreated areas all around in order to further maximize the service life of the entire component.

The material of the stroke segment, 1.2311 (40CrMnMo7), is perfect for laser hardening. This impressively demonstrates how important the right combination of material and surface treatment is for long-term success.

With laser hardening, we ensure targeted and effective hardening that reduces wear where it counts most.

Do you also have components that show wear problems?

We are happy to support you with customized solutions for your tools and components.